Overall lifting construction operation platform

A work platform and overall lifting technology, applied in construction, scaffolding accessories, housing structure support, etc., can solve problems such as easy shaking, avoid falling, facilitate subsequent lifting, and reduce the installation time of wall-penetrating components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

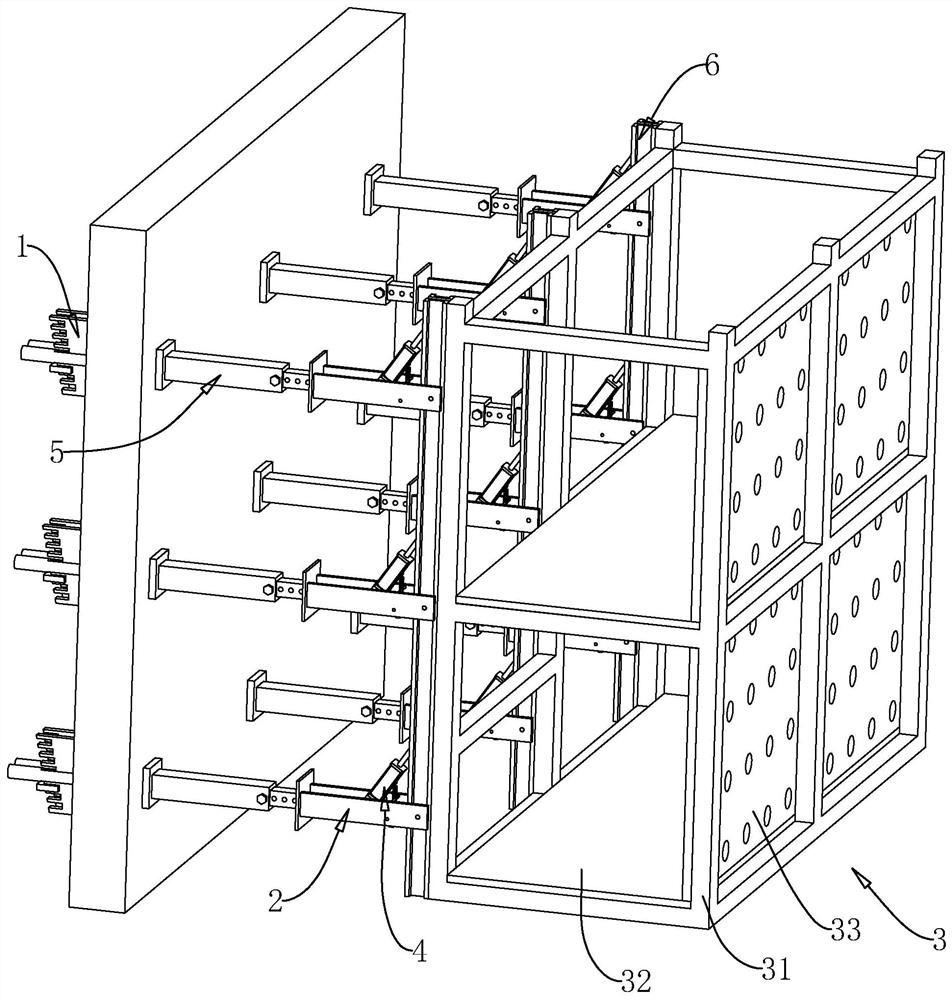

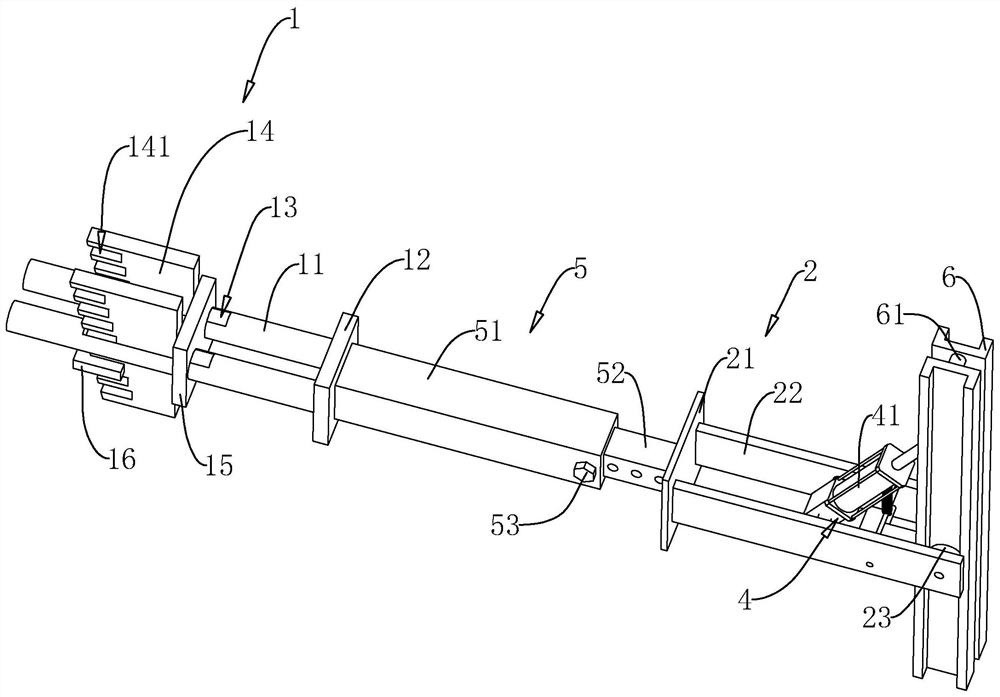

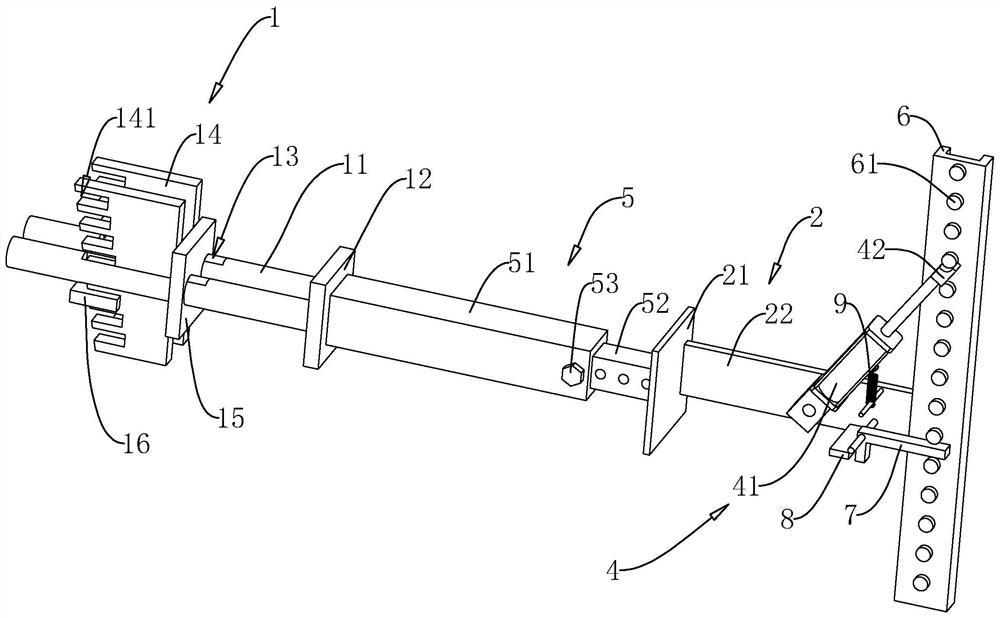

[0036] The following is attached Figure 1-3 The application is described in further detail.

[0037] The embodiment of the present application discloses an overall lifting construction work platform. refer to figure 1 , the overall lifting construction work platform includes a wall-through assembly 1 horizontally installed on the building wall, one end of the wall-through assembly 1 is located inside the wall, the other end is located outside the wall, and the wall-through assembly 1 located outside the wall The end is connected with an attachment support assembly 2, and a frame assembly 3 is arranged on the outside of the wall and along the height direction of the building. The frame assembly 3 can move vertically along the height direction of the wall, and the attachment support assembly 2 is away from the wall. The end of the component 1 is slidingly fitted with the frame component 3, and a power component 4 is arranged on the attachment support component 2. One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com