High-low voltage conversion circuit with low temperature coefficient and high power supply rejection ratio

A technology with high power supply rejection ratio and low temperature coefficient, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve problems such as complex circuit structure, consumption, unstable low-voltage power supply, etc., to simplify the circuit structure and reduce the number of chips The effect of area, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

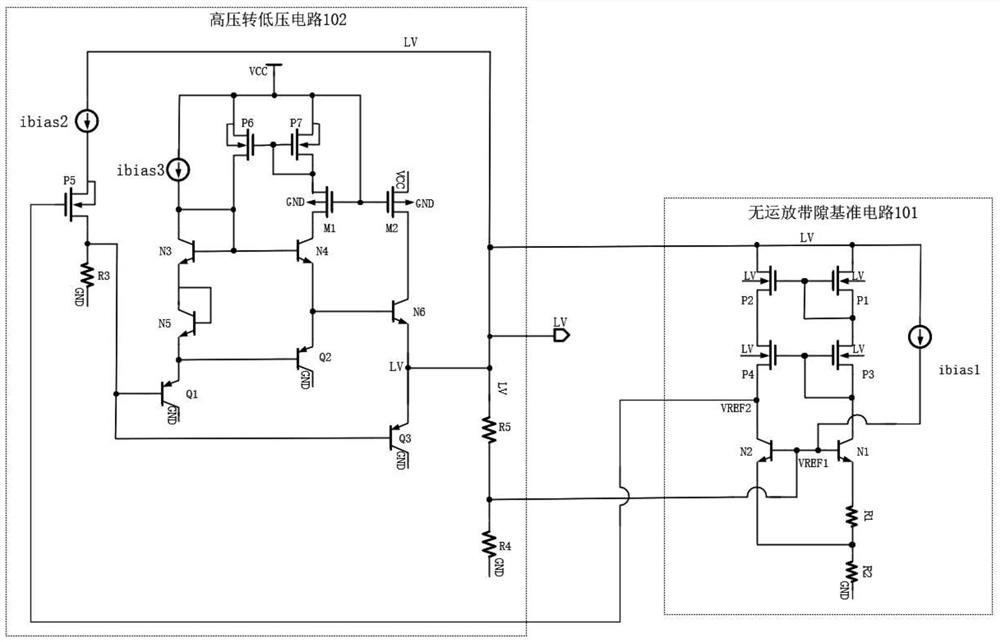

[0023] Embodiment 1: as figure 1 As shown, a high-voltage conversion circuit with a low temperature coefficient and a high power supply rejection ratio includes a non-op-amp bandgap reference circuit 101 and a high-voltage to low-voltage circuit 102; the non-op-amp bandgap reference circuit 101 and the high-voltage to low-voltage circuit 102 connect.

Embodiment 2

[0024] Embodiment 2: On the basis of Embodiment 1, the non-op-amp bandgap reference circuit 101 includes a first current generation unit, a low temperature coefficient bandgap reference voltage generation unit, a feedback voltage unit, and a second current generation unit; the first The current generation unit provides the first current to the entire non-op-amp bandgap reference circuit 101, the second current generation unit provides the second current to the bandgap reference voltage generation unit with low temperature coefficient, and the feedback voltage of the feedback voltage unit is sent to the high voltage to low voltage circuit 102.

Embodiment 3

[0025] Embodiment 3: On the basis of embodiment 2, the bandgap reference voltage generation unit of low temperature coefficient comprises NPN tube N1, NPN tube N2, resistor R1 and resistor R2; The emitter stage of NPN tube N1 and the lower end of resistor R1, resistor The upper end of R2 is connected; the emitter of NPN tube N2 is connected with the upper end of resistor R1; the lower end of resistor R2 is grounded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com