Non-convex variable contig sparse variation method for steel ingot ultrasonic signal noise reduction

An ultrasonic signal and contig technology, which is applied in the direction of using sonic/ultrasonic/infrasound for material analysis, processing the response signal of detection, analyzing material, etc. Amplitude attenuation, improve the effect of waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

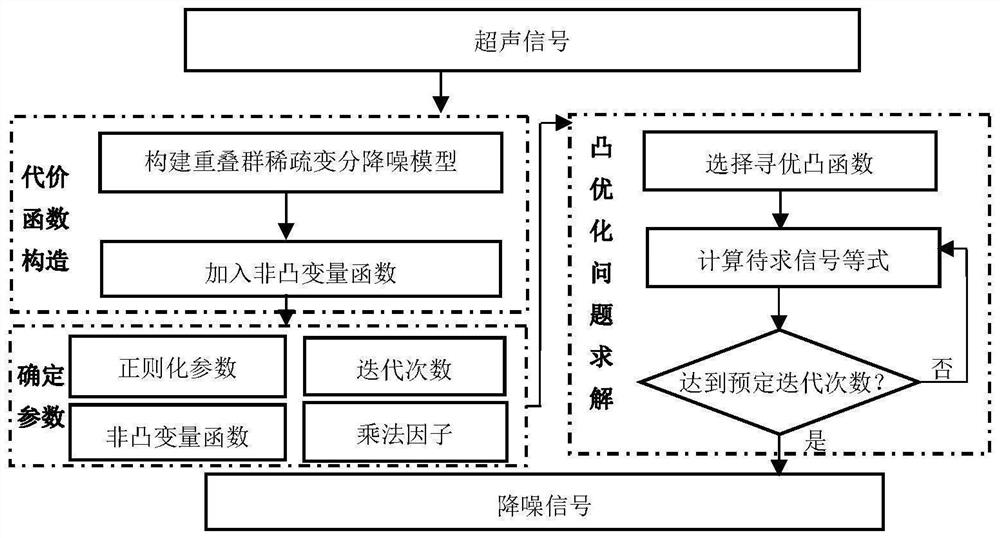

[0052] Combine below Figure 1 to Figure 9 , taking typical steel ingot ultrasonic signals and ultrasonic imaging as examples, the implementation process of the non-convex variable contig sparse variational method is described in detail.

[0053] (1) Non-convex variable contig sparse variation method for noise reduction analysis of steel ingot ultrasonic signal

[0054] The specific implementation steps of the non-convex variable contig sparse variation method for noise reduction of typical steel ingot ultrasonic signals are given below.

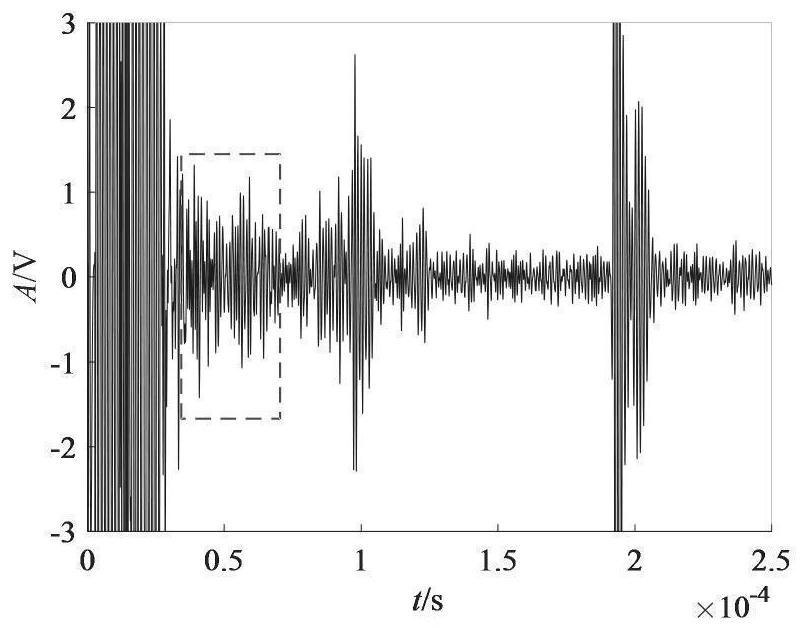

[0055] 1. Through the DPR 500 ultrasonic pulse transmitter receiver, use the Shanchao 1Z30N probe to collect the ultrasonic signal of the test piece 42CrMo die-cast billet steel ingot, figure 2 The time-domain waveform diagram of the ultrasonic signal of the steel ingot is given.

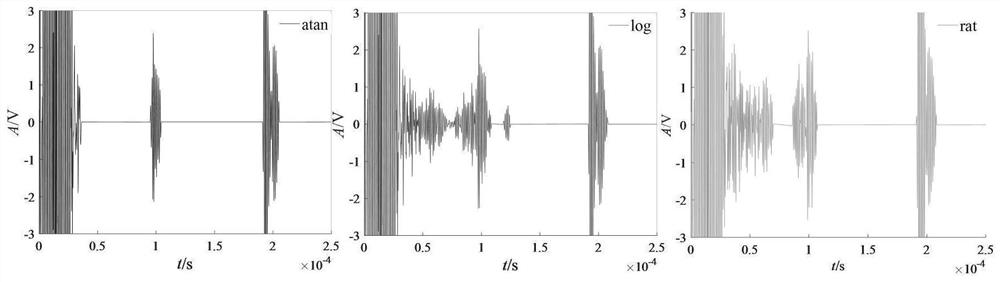

[0056] 2. Under the same regularization parameter and multiplication factor level, use three non-convex variable functions to perform non-convex variable conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com