Landscape planting soil particles as well as preparation method and use method thereof

A landscape and particle technology is applied in the field of landscape planting soil particles and their preparation, which can solve the problems of insufficient soil porosity and poor water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

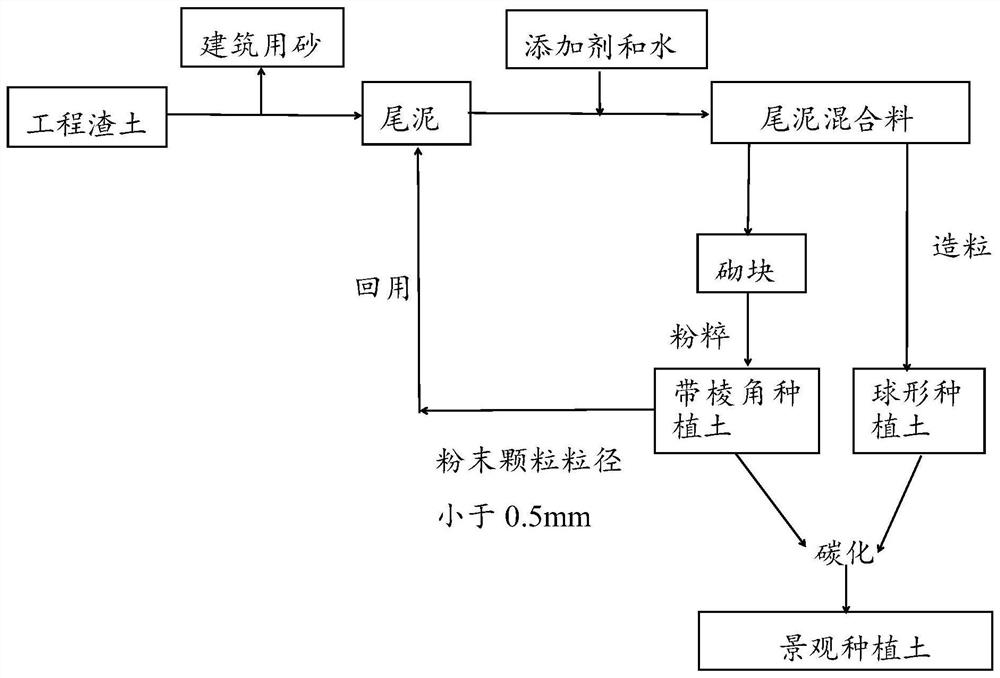

[0027] The invention provides a method for preparing landscape planting soil particles, comprising the following steps:

[0028] Mix tailings, additives and water to obtain tailings mixture;

[0029] Pretreating the tailings mixture to obtain primary planting soil;

[0030] Carbonizing the primary planting soil to obtain the landscape planting soil particles;

[0031] The pretreatment includes pouring-crushing and / or granulation;

[0032] The additives include binders, water reducers, foaming agents and nutrients.

[0033] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0034] The invention mixes tail mud, additives and water to obtain tail mud mixture.

[0035] In the present invention, the tailings are preferably obtained by washing engineering dregs to remove construction sand. In the present invention, the tailings preferably include more than 95% clay, and the clay...

Embodiment 1

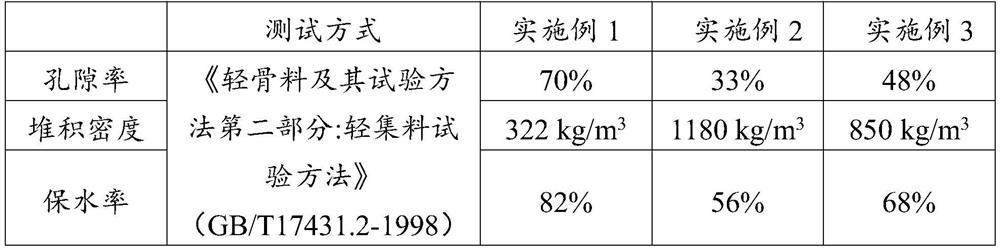

[0057] With 50 parts by weight of tailings (the composition of tailings is 97% clay and 3% impurity, and the composition of described clay is silicon oxide 62%, aluminum oxide 22%, iron oxide 5%, calcium oxide 4%, potassium oxide 4% %), 20 parts by weight of Portland cement, 0.5 parts by weight of polycarboxylate superplasticizer, 1 part by weight of sodium lauryl sulfate foaming agent, 2 parts by weight of vegetation leaves and 10 parts by weight of water are mixed to obtain tailings Mixture;

[0058] The tailing mud mixture is poured to obtain blocks, and then the blocks are crushed to obtain angular planting soil with a diameter ≥ 5 mm, and particles with a diameter of less than 0.5 mm are reused in the tail mud.

[0059] The obtained angular planting soil is carbonized to obtain landscape planting soil particles; the carbonization temperature is 25° C., the pressure is normal pressure, the carbonization humidity is 60%, the carbonization carbon dioxide concentration is ≥ 9...

Embodiment 2

[0061] With 50 parts by weight of tailings (the composition of tailings is 97% clay and 3% impurity, and the composition of described clay is silicon oxide 62%, aluminum oxide 22%, iron oxide 5%, calcium oxide 4%, potassium oxide 4% %), 20 parts by weight of Portland cement, 0.5 parts by weight of polycarboxylate superplasticizer, 1 part by weight of animal hoof horn type protein active material foaming agent, 2 parts by weight of vegetation fallen leaves and 10 parts by weight of water are mixed to obtain tail mud mixture;

[0062] The tailings mixture is granulated to obtain spherical planting soil with a diameter ≥ 5 mm, and the particles with a diameter of less than 0.5 mm are reused in the tailings.

[0063] The obtained spherical angle planting soil is carbonized to obtain landscape planting soil particles; the carbonization temperature is 25° C., the pressure is normal pressure, the carbonization humidity is 60%, the carbonization carbon dioxide concentration is ≥ 95%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com