Preparation method of heat storage material

A technology of heat storage material and phase change material, which is applied in the field of heat storage material preparation, can solve the problems of high melting point of industrial-grade paraffin, restrictions on the application of paraffin, and easy leakage of paraffin, so as to broaden the range of phase change temperature, improve latent heat value, Good heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

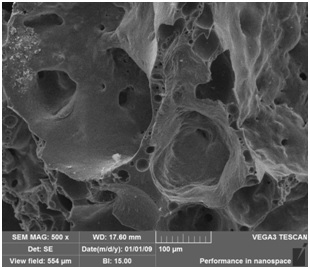

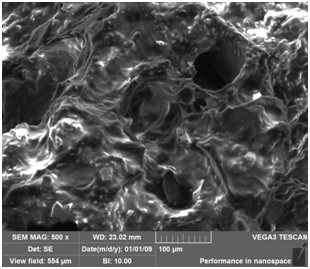

Image

Examples

Embodiment 1

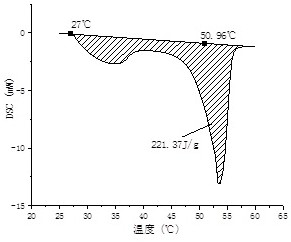

[0026] Example 1 Preparation of heat storage material 1

[0027] Heat 80g of 54# solid section paraffin in a water bath to 60°C to melt, then add 20g of liquid paraffin and stir and mix for 30min to obtain a binary phase change material with a melting point of 40°C, and the liquid paraffin accounts for the binary phase change The weight percentage of material is 20%;

[0028] Heat 20g of hexadecylamine to 80°C in a water bath to melt, then add 80g of the above-mentioned binary phase change material and stir and mix at 60°C to obtain a ternary phase change material, the hexadecylamine occupies the ternary phase The percentage by weight of variable material is 20%;

[0029] Heat and melt 99.5 g of the above-mentioned ternary phase-change material in a water bath, then add 0.5 g of nano-aluminum nitride, and stir evenly to obtain a quaternary phase-change material. The weight percentage is 0.5% by weight;

[0030] Add 60g of porous carrier ceramsite with a particle size not gr...

Embodiment 2

[0031] Example 2 Preparation of heat storage material 2

[0032] Heat 50g of 54# solid section paraffin in a water bath to 80°C to melt, then add 50g of liquid paraffin and stir and mix for 60 minutes to obtain a binary phase change material with a melting point of 25°C, and the liquid paraffin occupies the The weight percentage of the material is 50%;

[0033] Heat 40g of hexadecylamine to 100°C in a water bath to melt, then add 60g of the above-mentioned binary phase change material and stir and mix at 80°C to obtain a ternary phase change material, the hexadecylamine occupies the ternary phase The percentage by weight of variable material is 40%;

[0034] Heat and melt 98g of the above-mentioned ternary phase-change material in a water bath, then add 2g of nano-aluminum nitride, stir evenly to obtain a quaternary phase-change material, and the nano-aluminum nitride accounts for the weight of the quaternary phase-change material The percentage is 2% by weight;

[0035] Ad...

Embodiment 3

[0036] Example 3 Preparation of heat storage material 3

[0037] Heat 70g of 54# solid sliced paraffin in a water bath to 70°C and melt, then add 30g of liquid paraffin and stir and mix for 45min to obtain a binary phase change material with a melting point of 35°C. The weight percentage of the material is 30%;

[0038] Heat 35g of hexadecylamine to 90°C in a water bath to melt, then add 65g of the above binary phase change material and stir and mix at 70°C to obtain a ternary phase change material, the hexadecylamine occupies the ternary phase The percentage by weight of variable material is 35%;

[0039] Heat and melt 99 g of the above-mentioned ternary phase-change material in a water bath, then add 1 g of nano-aluminum nitride, stir evenly to obtain a quaternary phase-change material, and the nano-aluminum nitride accounts for the weight of the quaternary phase-change material The percentage is 1% by weight;

[0040] Add 65g of porous carrier ceramsite with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com