Trimethylgallium on-line analysis device and analysis method thereof

A trimethylgallium and analysis device technology, which is applied in the field of trimethylgallium online analysis devices, can solve the problems of inflexible connection of sampling analysis, trimethylgallium sampling and analysis, etc., achieve convenient and efficient sample recovery, avoid interference, exhaust gas, etc. receive convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

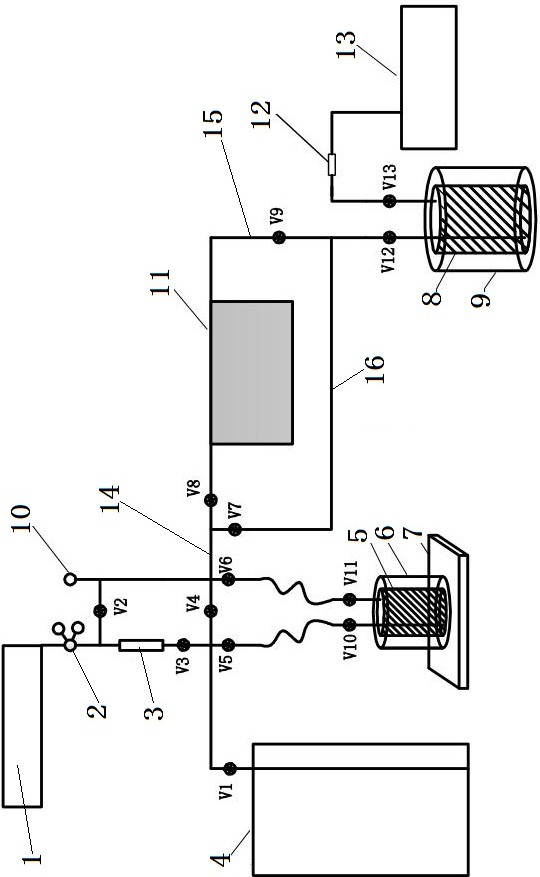

[0027] like figure 1 As shown, the present embodiment provides a trimethylgallium online analysis device, including a trimethylgallium storage tank 4, the trimethylgallium storage tank 4 is connected to the gas chromatograph 11 through a pipeline one 14, and the pipeline one 14 connected to the sampling bottle 5, the gas chromatograph 11 is connected to the absorption tank 8 by the pipeline two 15, and the absorption tank 8 is connected with the vacuum pump 13; the pipeline one 14 and the pipeline two 15 are also connected by the pipeline three 16; the sampling The bottle 5 is covered with a heating pack 6, and the bottom of the sampling bottle 5 is provided with an electronic scale 7; the absorption tank 8 is provided with a cold hydrazine 9, and liquid nitrogen is poured into the cold hydrazine 9 for cooling; the pipeline one 14 is also connected with The mass flow meter 3 and the pressure gauge 10 are connected to the mass flow meter 3 with a pressure reducing valve 2 conne...

Embodiment 2

[0030] This embodiment provides a trimethylgallium online analysis method:

[0031] Step 1: Front replacement: first turn on the vacuum pump 13, close the valves V1, V2, V3, V7, V8, and V9, open the valves V4, V5, V6, V10, V11, V12, and V13, and set the pressure of the pressure reducing valve to 20.4 Mpa, open the valve V2 to replenish nitrogen until the pressure gauge 10 shows 0.4Mpa, then close it, open the valve V7 and then close it after evacuating for 5 minutes, this is a replacement, repeat the operation 5 times to complete the replacement, and finally close the valves V5, V6, V10, V11, the replacement After completion, ensure that the pipeline is not disturbed by other impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com