Silicon carbide crystal ingot bonding and machining equipment capable of automatically centering and method thereof

A processing equipment, silicon carbide technology, applied in mechanical equipment, material gluing, connecting components, etc., can solve the problems of resource cost waste, processing failure, difficult concentricity, etc., achieve fast and accurate positioning, improve bonding efficiency, and improve adhesion. The effect of combined efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

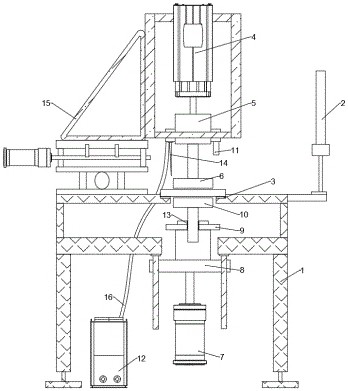

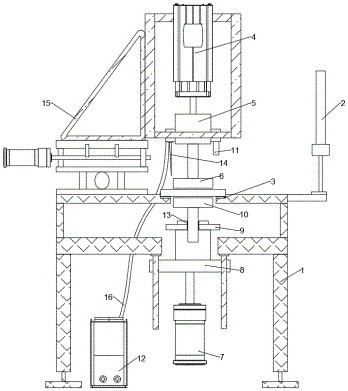

[0035] Such as figure 1 As shown, a silicon carbide ingot bonding processing equipment that can be automatically centered includes a machine body 1, an industrial computer 2, a ring-shaped workbench 3 fixed on the machine body 1, and a sliding connection to the machine body. The telescopic cylinder 4 on 1, the first clamping mechanism 5 fixedly connected to the telescopic cylinder 4, the first bonding jig 6 connected to the first clamping mechanism 5, and the lifting module fixed on the machine body 1 7. The second clamping mechanism 8 fixedly connected with the lifting module 7, the positioning plate 9 installed on the second clamping mechanism 8, the second bonding jig 10 connected to the second clamping mechanism 8, and the second A distance measuring sensor 11 fixedly connected to a clamping mechanism 5, a bonding wax spray device 12 arranged on the machine body 1, a needle-shaped bonding wax spray head 14 fixedly connected to the first clamping mechanism 5, a horizontal d...

Embodiment 2

[0043] Different from Embodiment 1, the center of the machine body 1 can be provided with a ladder-shaped building groove, and the workbench 3 is fixed on the machine body 1 in a stacked manner, which is convenient for the lifting module 7 to drive the second bonding process. The tool 10 moves up and down through the workbench 3, and the workbench 3 of different sizes can be replaced according to the size of the silicon carbide ingot. The workbench 3 enables the silicon carbide ingots of different sizes to be placed on the machine body 1 smoothly. In the example, a 6-inch positioning flat plate 9 is selected, and the positioning hole 13 provided thereon has a size of 130mm, which is used to support a 6-inch silicon carbide crystal ingot.

[0044] The first clamping mechanism 5 and the second clamping mechanism 8 are centering chucks, which can be pneumatic three-jaw or four-jaw chucks, and are used to clamp the first bonding fixture 6 or the second bonding fixture 10 the end. ...

Embodiment 3

[0047] A method for bonding silicon carbide crystal ingots that can be automatically centered, using the equipment in Embodiment 2, comprising the following steps:

[0048] S1. Assemble and inspect silicon carbide ingot bonding processing equipment

[0049] S11. Check whether the telescopic cylinder 4, the first clamping mechanism 5, the lifting module 7, and the second clamping mechanism 8 are operating normally;

[0050] S12. Fixing the first bonding jig 6 with the first clamping mechanism 5 is equivalent to fixing the first bonding jig 6 with the telescopic cylinder 4;

[0051] S13. Select a 6-inch positioning plate 9 and install it on the second clamping mechanism 8, and set the end of the second bonding jig 10 in the positioning round hole 13 to realize the fixing of the center of the second bonding jig 10 , and then use the second clamping mechanism 8 to clamp the second bonding jig 10;

[0052] S14. Check whether the silicon carbide ingot bonding processing equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com