Silane crosslinked polyethylene resin composition for pipes and method for preparing pipes

A polyethylene resin, silane cross-linking technology, applied in the direction of tubular articles, applications, household appliances, etc., can solve the problem of high temperature creep resistance of cross-linked polyethylene not involving silane, and achieve excellent long-term hydrostatic strength, excellent resistance to The effect of high temperature creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

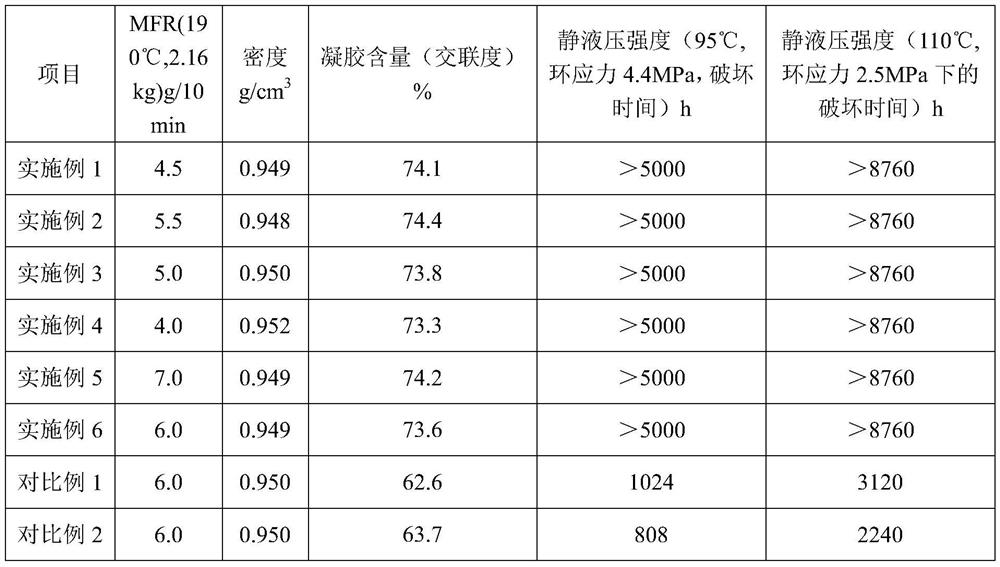

Examples

Embodiment 1

[0029] The composition ratio (by weight) of the silane crosslinked polyethylene resin composition for pipes is as follows:

[0030] Polyethylene resin: 100 parts;

[0031] Vinyltrimethoxysilane (A171): 2.0 parts;

[0032] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane: 0.2 parts;

[0033] Hindered phenol antioxidant: tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 0.1 part;

[0034] Phosphite antioxidant: tris[2.4-di-tert-butylphenyl] phosphite: 0.1 part;

[0035] Dibutyltin dilaurate: 0.1 parts.

[0036] Among them, the MFR (190°C, 2.16kg weight) of polyethylene resin is 4.5g / 10min, and the density is 0.949g / cm 3 .

[0037] Preparation method: Add polyethylene resin, unsaturated silane, grafting initiator and antioxidant into the extruder respectively, and in the presence of grafting initiator, polyethylene resin is grafted with unsaturated silane to form silane grafted polymer. Ethylene, and extruded pipe; then under the action of water...

Embodiment 2

[0039] The composition ratio (by weight) of the silane crosslinked polyethylene resin composition for pipes is as follows:

[0040] Polyethylene resin: 100 parts;

[0041] Vinyl tri(methoxy-ethoxy) silane (A-172): 2.0 parts;

[0042] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane: 0.15 parts;

[0043] Hindered phenol antioxidant: 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanate: 0.15 parts;

[0044]Phosphite antioxidant: tris[2.4-di-tert-butylphenyl] phosphite: 0.15 parts;

[0045] Dibutyltin dilaurate: 0.2 parts.

[0046] Among them, the MFR (190°C, 2.16kg weight) of polyethylene resin is 5.5g / 10min, and the density is 0.948g / cm 3 .

[0047] Preparation method: Add polyethylene resin, unsaturated silane, grafting initiator and antioxidant into the extruder respectively, and in the presence of grafting initiator, polyethylene resin is grafted with unsaturated silane to form silane grafted polymer. Ethylene is extruded into a pipe; then under the action of water and...

Embodiment 3

[0049] The composition ratio (by weight) of the silane crosslinked polyethylene resin composition for pipes is as follows:

[0050] Polyethylene resin: 100 parts;

[0051] Vinyltriethoxysilane (A151): 2.5 parts;

[0052] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane: 0.1 parts;

[0053] Hindered phenol antioxidant: 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene: 0.2 parts;

[0054] Phosphite antioxidant: tris[2.4-di-tert-butylphenyl] phosphite: 0.2 parts;

[0055] Dibutyltin dilaurate: 0.15 parts;

[0056] Among them, the MFR (190°C, 2.16kg weight) of polyethylene resin is 5.0g / 10min, and the density is 0.950g / cm 3 .

[0057] Preparation method: Add polyethylene resin, unsaturated silane, grafting initiator and antioxidant into the extruder respectively, and in the presence of grafting initiator, polyethylene resin is grafted with unsaturated silane to form silane grafted polymer. Ethylene is extruded into a pipe; then under the action of water and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com