Manufacturing process of non-woven fabric artificial flower and artificial flower

A production process and non-woven fabric technology, which is applied in artificial flowers, non-woven fabrics, textiles and papermaking, etc., can solve the problems of affecting processing efficiency and cutting effect, limiting the production efficiency of artificial flowers, and detaching edges, etc. Achieve better and richer colors, improve production efficiency, and lower VOC release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-4

[0064] Preparation examples 1-4 all relate to a kind of non-woven fabric preparation process, and the process steps are as follows:

[0065] Step 1. Dry the spinning particles at 160-175°C, and then heat to 250-270°C to melt the spinning particles to form a spinning material; the spinning particles can be PET particles, PP particles, or PET particles and PBT particles mixture;

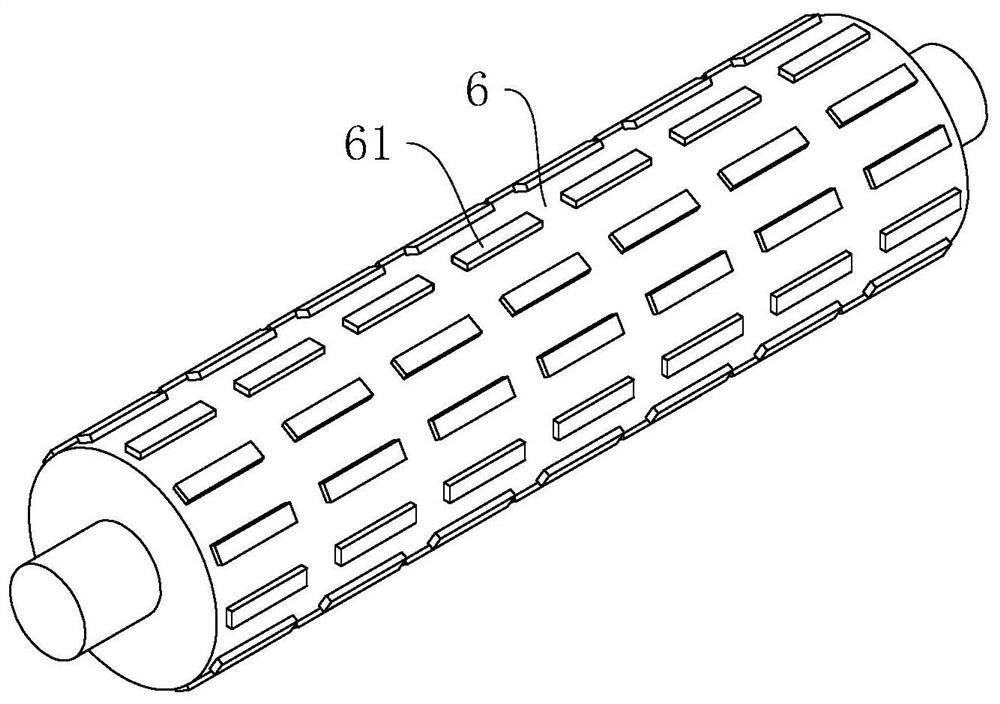

[0066] Step 2, the spinning material is sprayed through the spinneret and spun into fiber filaments with a thickness of 1-2D;

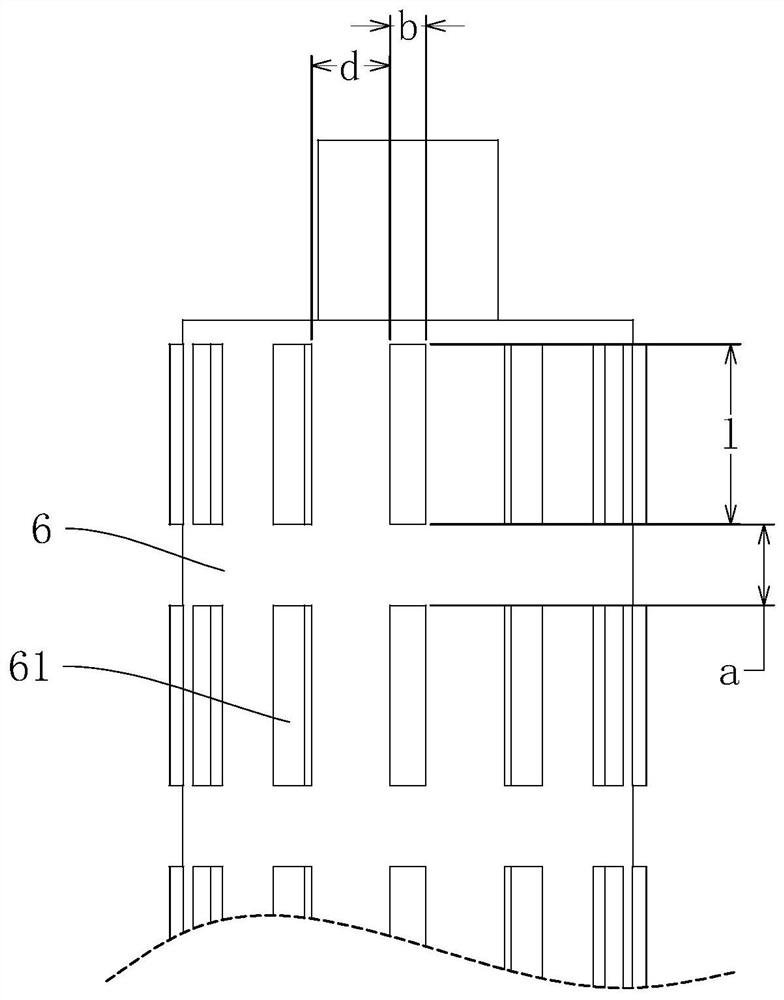

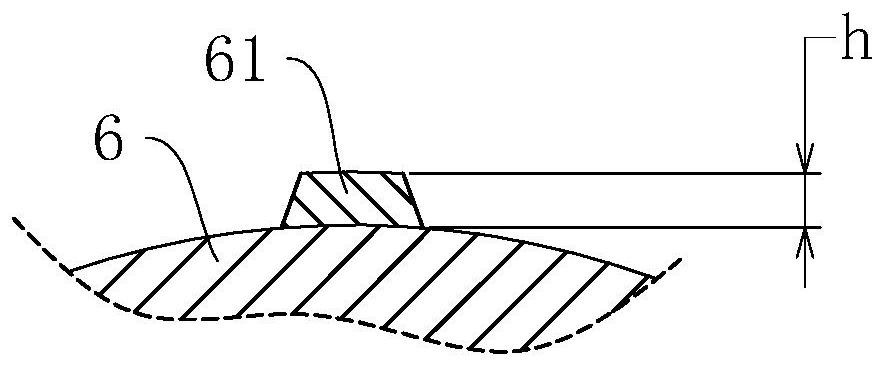

[0067] Step 3. After the fiber filaments are flattened into a web, use at least one embossing roller to cooperate with the pressure roller to carry out hot pressing and shaping to obtain a grammage of 20-120g / m 2 The surface of the embossing roller is evenly distributed with embossed bumps, the embossed bumps are in the shape of straight lines or curved strips, and the cross-section is rectangular or trapezoidal. When choosing multiple embossing rollers and backing rollers f...

Embodiment 1

[0087] A kind of non-woven fabric imitation flower production process, with the non-woven fabric that preparation example 1 makes as petal production raw material, refer to Figure 6 , the specific process steps are as follows:

[0088] (1) Cutting process

[0089] The non-woven fabric is cut into petal shapes to obtain cutting pieces. In order to facilitate the subsequent clamping and fixing device by means of the blank, a through hole is formed in the central part of the cut blank synchronously during cutting. In order to improve the cutting effect, 2 to 20 pieces of non-woven fabrics can be laminated and then cut synchronously during cutting, so that multiple petal-shaped cutting pieces can be obtained at one time. In this example, when cutting, 10 sheets of nonwoven fabrics were laminated at a time.

[0090] (2) Dyeing process

[0091] refer to Figure 7 and Figure 8 , the dyeing process needs to be completed by clamping and fixing the tablet. The sheet clamping an...

Embodiment 2

[0105] A non-woven fabric artificial flower production process, using the non-woven fabric prepared in Preparation Example 2 as the raw material for making petals, the difference from Example 1 is that the process parameters of each step are different, see Table 4 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com