Sleeve grouting reinforcing steel bar interlocking joint and full-prefabrication construction method for shear wall through sleeve grouting reinforcing steel bar interlocking joint

A sleeve grouting and shear wall technology, which is applied to walls, buildings, building reinforcements, etc., can solve the problems of high cost of joints, not dense grouting, and difficult grouting, etc., and achieve the goal of improving construction efficiency and improving prefabricated assembly rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

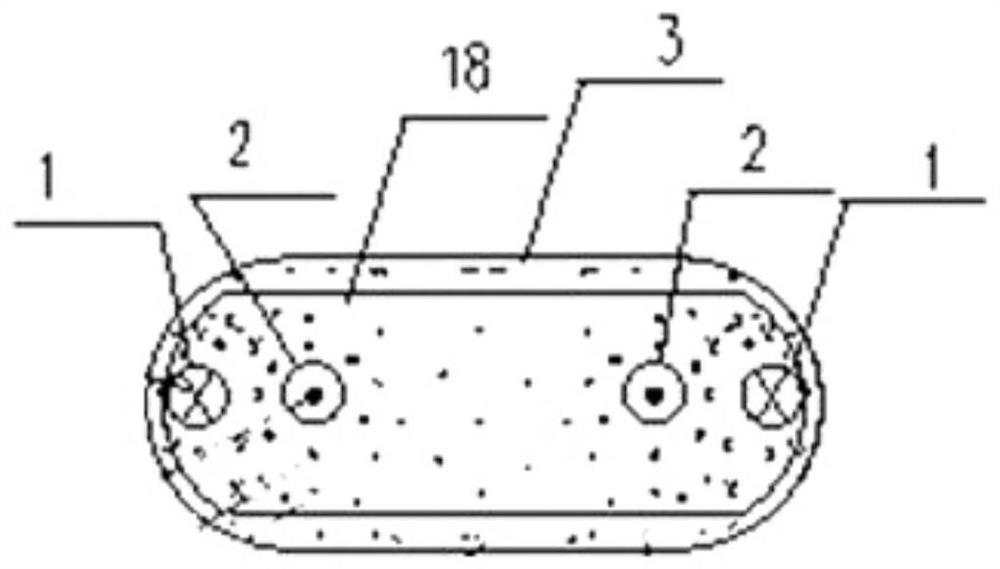

[0090] Such as figure 2 Shown: a sleeve grouted steel bar interlocking joint, mainly used for the connection of steel bars in the edge members of prefabricated shear walls, which includes two sets of first steel bar 1 and second steel bar 2 with opposite directions of force, for example and not limitation , there are two steel bars in each group, and four steel bars are placed in an oval sleeve 3, wherein the two first steel bars 1 are respectively connected to the inner walls of both sides of the sleeve 3 by spot welding, and the two first steel bars 1 are The upper part protrudes upwards along the inner wall of the sleeve 3, the two second steel bars 2 are placed in the lower part of the sleeve 3 and are respectively located inside the two first steel bars 1, and the lower parts of the two second steel bars 2 protrude toward the lower part of the sleeve 3; The lower part of the sleeve 3 is provided with a sleeve grouting port 4, and the upper part of the sleeve 3 is provide...

Embodiment 2

[0122] By way of example and not limitation, this embodiment provides a specific implementation of the interlocking joint of four steel bars grouted in a cylinder, in order to analyze and demonstrate the feasibility, performance and effect of the interlocking joint of this application.

[0123] (1), composition of grouting sleeve self-locking joint

[0124]a) Sleeve 3. The sleeve is generally composed of two circular arcs and a rectangle. The sleeve is processed by hot-rolling steel plates. The inner and outer walls do not need to be processed, and the cost is low. Considering the convenience of construction and the constraints of the sleeve, the optimal shape of the sleeve is shown in Figure 15. By increasing the thickness of the sidewall on the long side of the sleeve, the sleeve constraint is increased, which is unique to this application.

[0125] When the diameter of the steel bar is 12, 14, 16, 18, 20mm, the length of the sleeve can be increased by 2d-3d, and the transv...

Embodiment 3

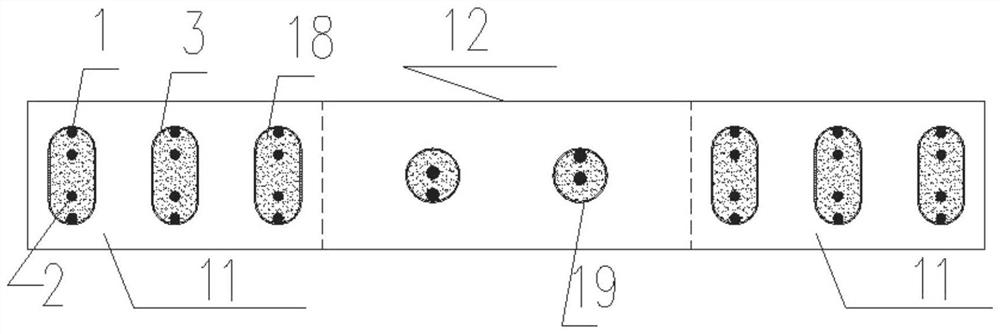

[0156] Such as image 3 , 4 , 5, 18 A fully prefabricated construction method for a shear wall, the above-mentioned interlocking joint is applied to the edge member 11 of the shear wall, so that the prefabricated assembled shear wall is a fully prefabricated component, the prefabrication rate is improved, and the shear force is avoided. Wet work on the wall speeds up the construction progress. The specific steps are as follows:

[0157] The first step: the factory makes the upper shear wall 7, the upper shear wall 7 includes the edge member 11 of the shear wall and the wall body 12 of the shear wall, and the wall body 12 of the shear wall is provided with a prefabricated wall body sleeve 28. The prefabricated wall body sleeve 28 is provided with a prefabricated wall middle steel bar joint 19, a prefabricated wall middle and upper shear wall steel bar 26, and a prefabricated wall middle and lower shear wall middle steel bar 27;

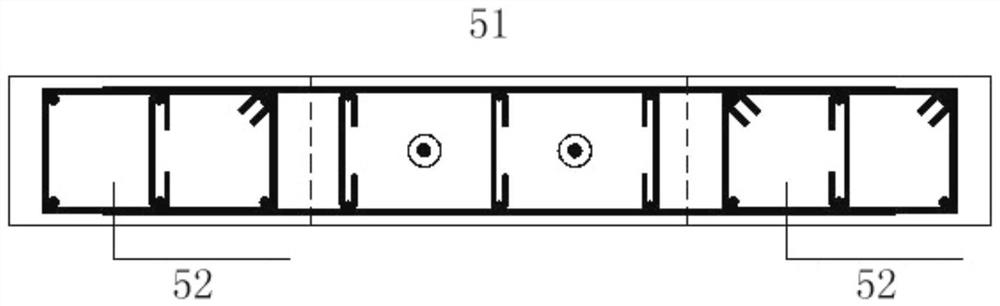

[0158] The second step: make some sleeves 3, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com