Temperature control device, hydraulic steering system and commercial vehicle

A temperature control device and steering system technology, which is applied in the field of commercial vehicles, can solve problems such as the inability to actively control the working temperature of the hydraulic oil of the system, the bursting of radiators and low-pressure oil pipes, the increase of system energy consumption and the heat production of the system, and achieve a good heat dissipation effect , fast heat dissipation, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

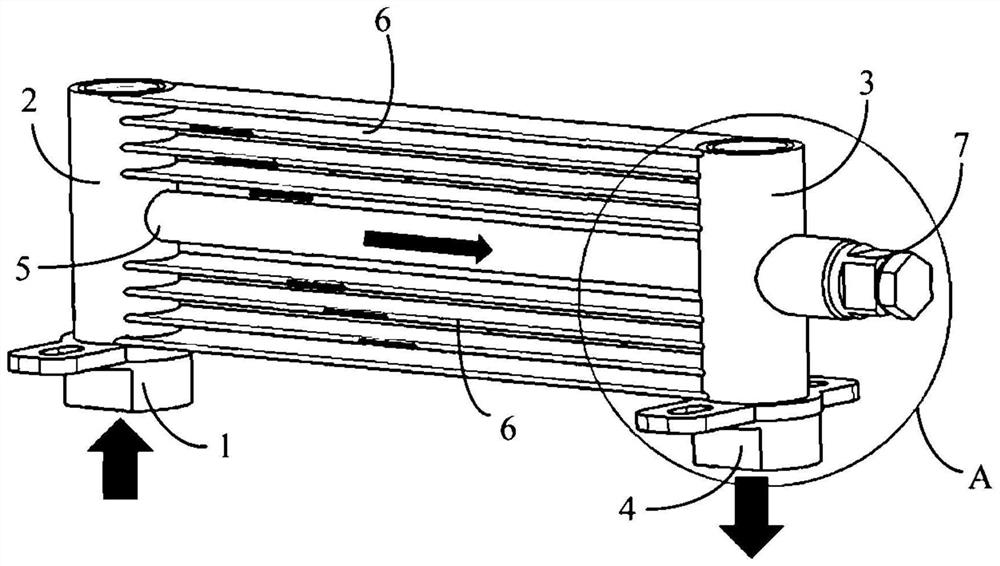

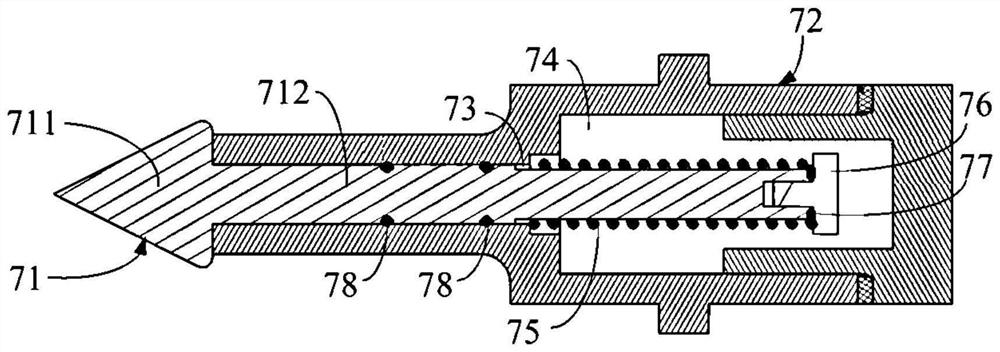

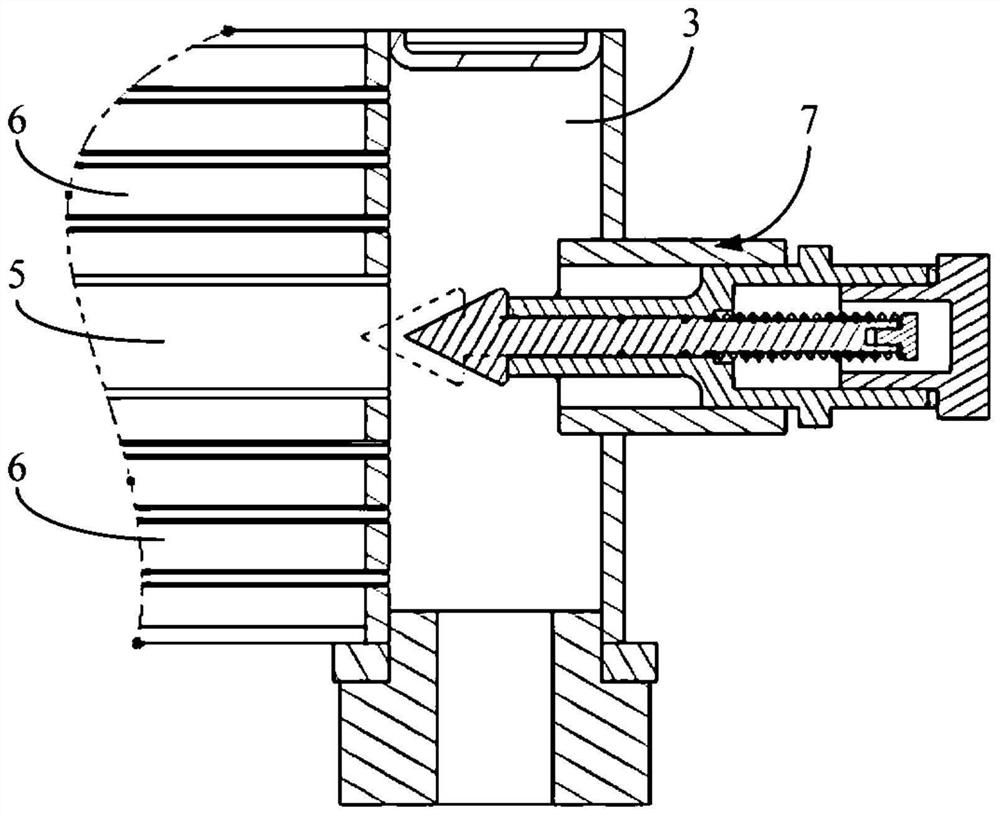

[0040]The plurality of auxiliary passages 6 are always fully open, and no valve may be provided to control the opening and closing of the auxiliary passages 6 or to adjust the flow of the auxiliary passages 6 . The flow rate of the main channel 5 is controlled by a temperature control valve assembly 7 . The temperature control valve assembly 7 is configured to control the flow rate of the main channel 5 to decrease when the temperature of the hydraulic oil increases, and to control the flow rate of the main channel 5 to increase when the temperature of the hydraulic oil decreases. The main channel 5 is set such that its channel resistance when it is in a fully open state is smaller than that of the auxiliary channel 6 when it is in a fully open state. The main channel 5 can be cylindrical, for example, and its flow resistance is relatively small when the channel is fully open.

[0041] By setting the temperature control valve assembly 7 to control the flow rate of the main ch...

Embodiment 2

[0048] The difference between the second embodiment and the first embodiment is that the positions of a plurality of auxiliary channels 6 and the main channel 5 are limited in the second embodiment, and the plurality of auxiliary channels 6 are spaced apart and stacked, and are arranged on the main channel 5 on the same side.

Embodiment 3

[0050] The difference between the third embodiment and the second embodiment is that in the third embodiment, the plurality of auxiliary channels 6 are divided into two groups of auxiliary channels, and the two groups of auxiliary channels are respectively arranged on both sides of the main channel 5, and each group The auxiliary channel group includes a plurality of auxiliary channels 6 . Compared with the solution in which multiple auxiliary channels 6 are arranged on the same side of the main channel 5, in the solution of the embodiment of the present invention, since the auxiliary channel groups are respectively arranged on both sides of the main channel 5, the overall structure of the temperature control device is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com