PDMS photoetching micro-nano bubble preparation method and micro-nano bubble test method

A technology of micro-nano bubbles and photolithography, which is applied in the preparation of test samples, the mixing of gas/vapor and liquid, and the analysis of materials through optical means, can solve the problems of lack of production methods for large-scale production of micro-nano bubbles, and achieve The effects of test comprehensiveness, comprehensive functions and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

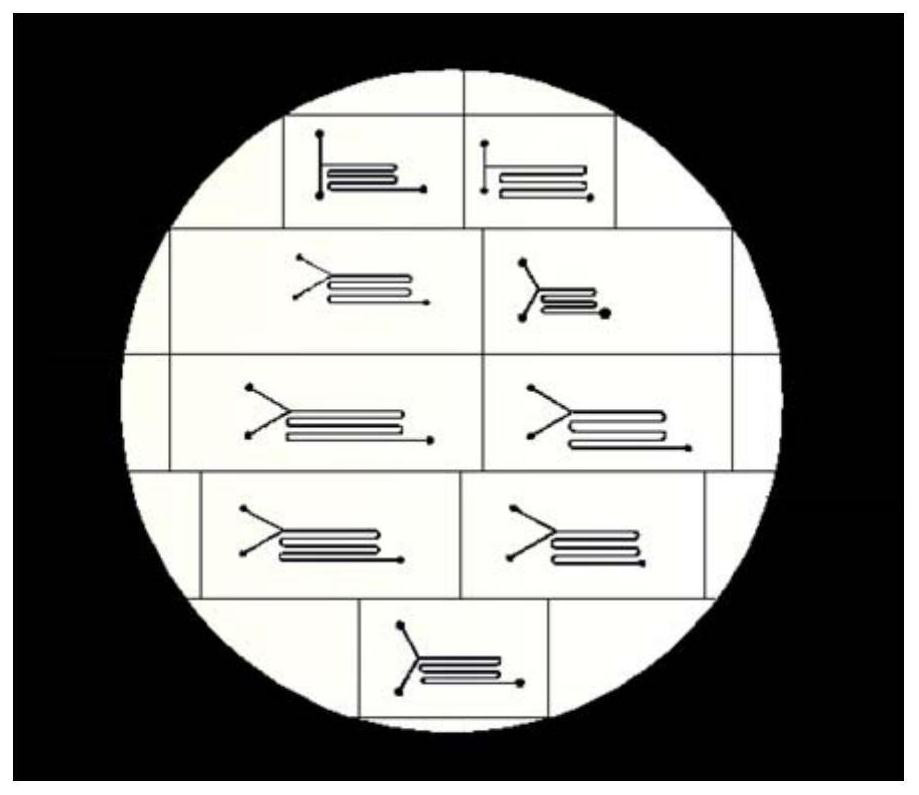

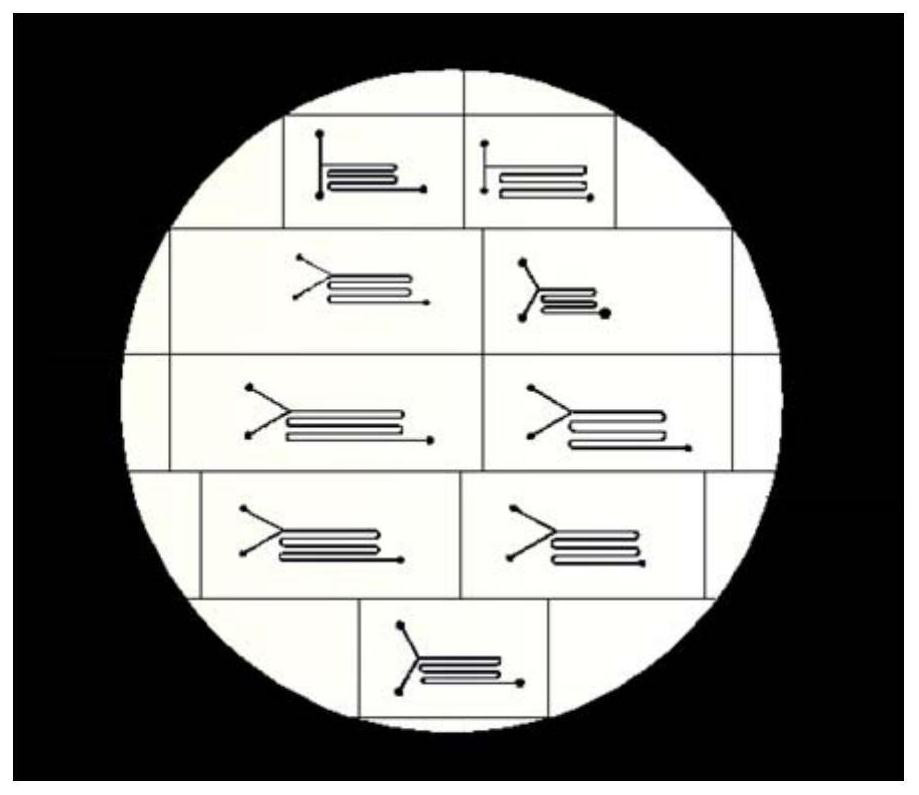

[0028] to combine figure 1 — figure 2 As shown, the preparation method of PDMS photolithography micro-nano bubbles comprises the following steps:

[0029] Step A, set up a nano-bubble generating device; the device consists of a micro-flow pump equipped with a liquid injector and controlling the flow rate of the liquid, a micro-flow pump equipped with a gas injector and controlling the flow rate of the gas, and a quick photo and screenshot software installed for real-time observation The computer for the flow of liquid and gas in the channel and the movement of the bubbles, and the microscope for magnifying the channel to facilitate seeing clear bubbles on the display are connected to each other.

[0030] Step B, micro-channel design and template production; design nine types of micro-channels with different channel widths and different angles between the two entrances of the channel, make a mask according to the channel diagram, and clean the mask with alcohol After drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com