Rapid repair process for external insulation of water immersion power secondary equipment

A technology for secondary equipment and external insulation, applied in electrical components, detergent compositions, cleaning methods and utensils, etc., can solve problems such as corrosion damage to lines, equipment, damage to external insulation of equipment, and safe power supply. The effect of repairing process science, shortening power outage time and saving manpower and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

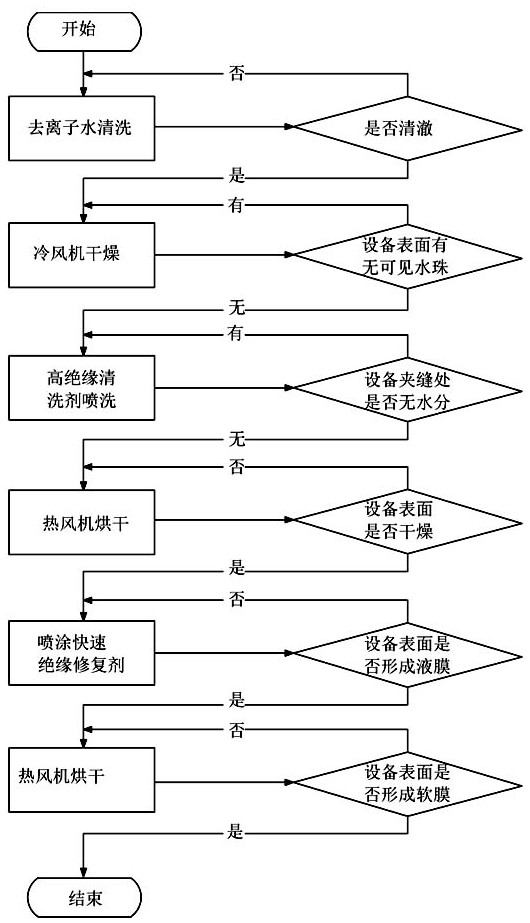

[0020] The process flow of the present application will be described in detail below to facilitate the understanding of those skilled in the art.

[0021] The electrical secondary equipment described in the present invention includes electrical equipment such as various motors, generators, transformers, relays, switches, commutators, brushes, batteries, and antennas.

[0022] Such as figure 1 As shown, the rapid repair process of the external insulation of the water-immersed power secondary equipment of the present invention comprises the following steps:

[0023] first step, washing

[0024] According to the provisions of GB / T 11446.1 "Electronic Grade Water", deionized water of EW-Ⅳ grade and above that removes anions and cations in water is used to remove conductive anions and cations while removing sediment stains. In order to ensure the insulation performance of the equipment; when cleaning, control the pressure of the spray gun to 0.4-0.6Mpa (the maximum cannot exceed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com