Super-large-specification wind power rotor workpiece and intelligent assembly system and assembly method thereof

A super-sized rotor technology, which is applied in the super-large wind power rotor workpiece and its intelligent assembly system and assembly field, can solve the problem of unreasonable and intelligent structural design of the rotor workpiece, inability to realize component transportation and assembly, adverse effects of permanent magnet magnetism, etc. problems, to achieve the effect of convenient assembly and operation, reduced transportation difficulty, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

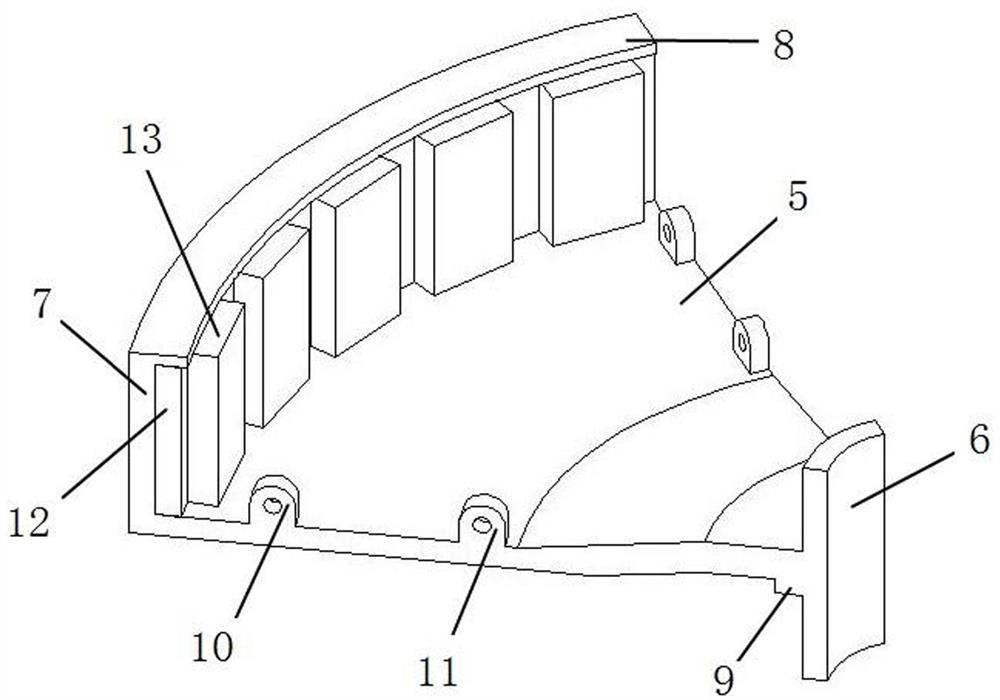

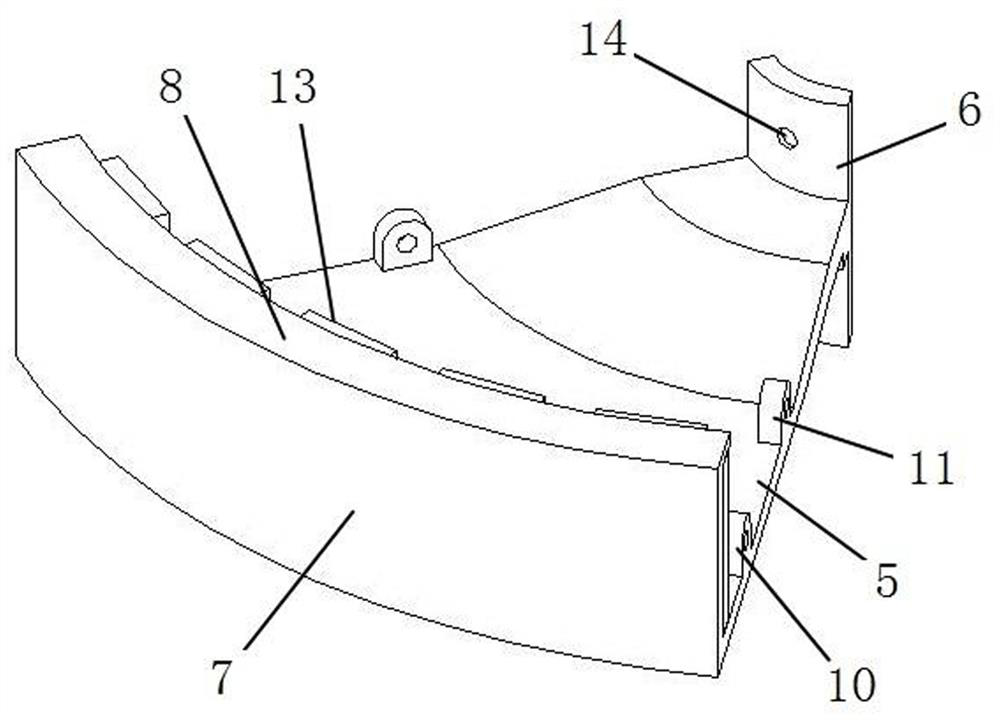

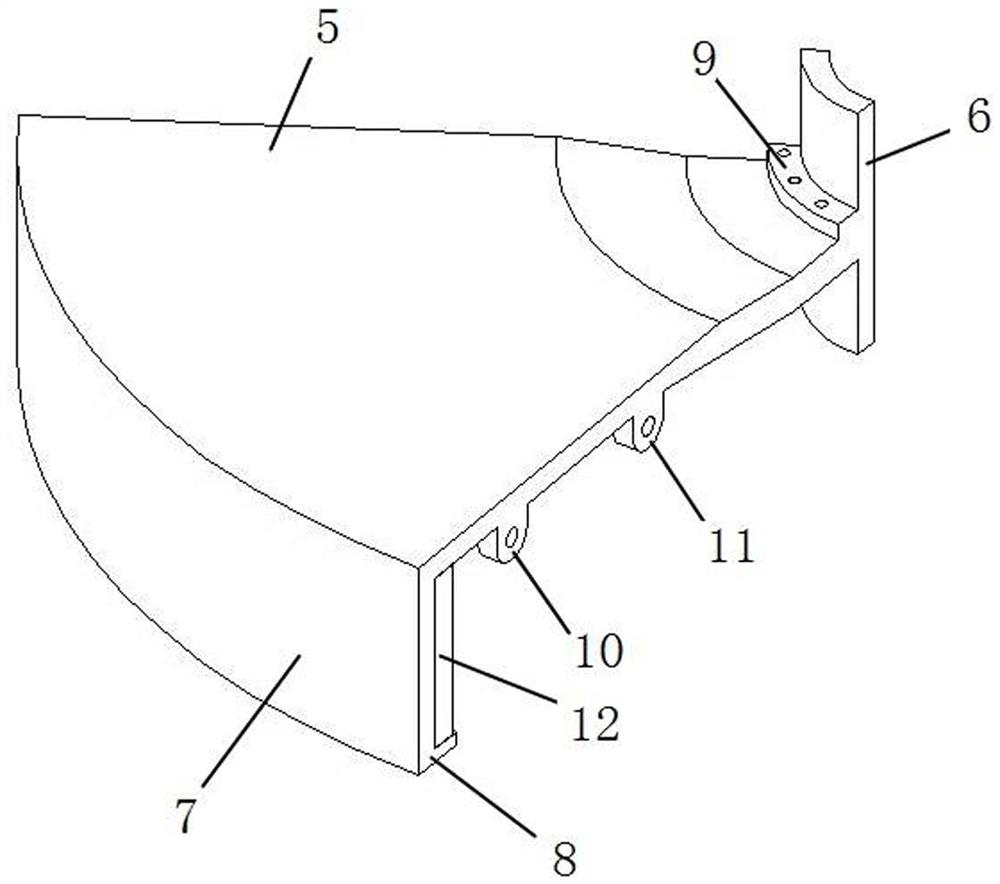

[0040] This embodiment is a super-sized wind power rotor workpiece. The rotor workpiece is a combined outer rotor structure, including six rotor module units distributed in an annular array. The outer diameter of the rotor workpiece is 0.8-3m.

[0041]In this embodiment, the rotor module unit includes a mounting block, a non-magnetic heat conducting strip 12 and a permanent magnet block 13 made of permanent magnets. The mounting block consists of a yoke plate 5, an inner arc-shaped sleeve plate 6, and an outer arc-shaped mounting plate 7 , The baffle plate 8, the first ear plate 10 and the second ear plate 11 constitute. Wherein, the yoke plate 5 has a fan-shaped plate structure, and its central angle is 60 degrees. The inner end of the yoke plate 5 is connected with an inner arc-shaped sleeve plate 6 , and the outer end is connected with a baffle plate 8 through an outer arc-shaped mounting plate 7 . The two sides of the yoke plate 5 are respectively provided with a first lu...

Embodiment 2

[0046] This embodiment is improved on the basis of Embodiment 1. The inner side of the non-magnetic heat-conducting strip 12 is preformed with an installation groove for easy installation of the permanent magnet block 13, and the outer side of the permanent magnet block 13 is provided with a two-dimensional code for marking its installation position. , the non-magnetic heat conduction strip 12 is made of transparent magnesia ceramic material which is convenient for observing the two-dimensional code on the outside of the permanent magnet block 13. The transparent magnesia ceramic material has the advantages of non-magnetic heat conduction and transparency, and the present invention innovatively uses it as a permanent magnet block Carrier.

[0047] A specific application of this embodiment is: the permanent magnet block 13 and the carbon steel rotor rim (that is, the installation area formed by the yoke plate 5, the outer arc-shaped installation plate 7, and the baffle plate 8) ...

Embodiment 3

[0049] This embodiment is improved on the basis of Embodiment 1. The outer side of the non-magnetic heat conducting strip 12 is provided with a positioning groove, and the inner side of the outer arc-shaped mounting plate 7 is provided with a positioning protrusion, and the positioning protrusion cooperates with the positioning groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com