Harness assembly line balancing

A wire harness and processing device technology, applied in the field of electronic design automation, can solve problems such as manufacturing bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

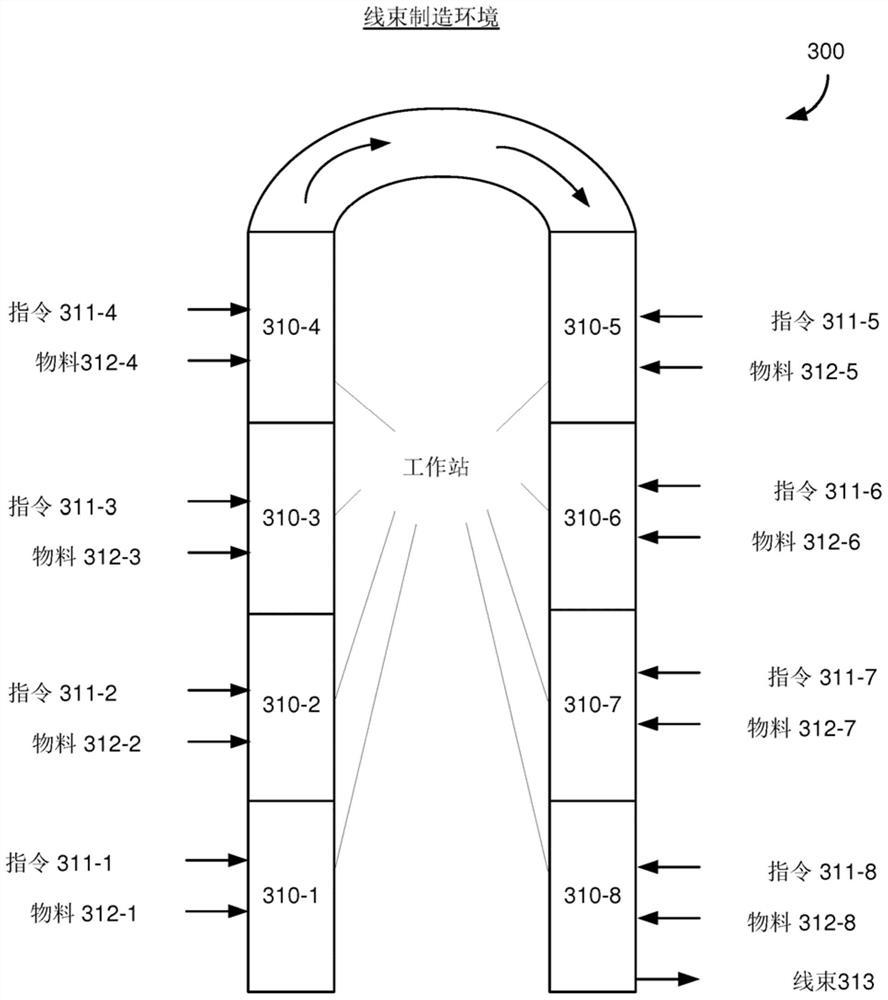

[0015] Illustrative Operating Environment

[0016] Execution of various electronic design automation processes according to various embodiments may be implemented using computer-executable software instructions executed by one or more programmable computing devices. Since these embodiments may be implemented using software instructions, the components and operations of a general-purpose programmable computer system that may utilize various embodiments will first be described. Furthermore, due to the complexity of some electronic design automation processes and the sheer scale of many circuit designs, various electronic design automation tools are configured to operate on computer systems capable of running multiple processing threads simultaneously.

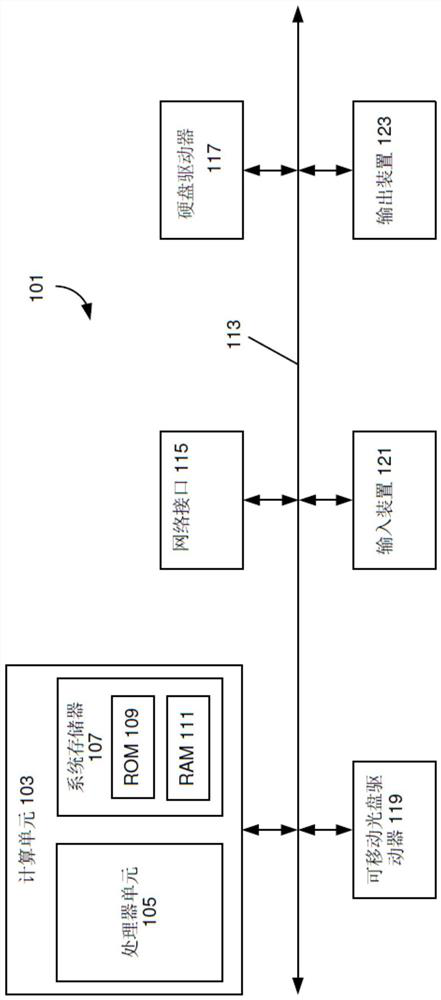

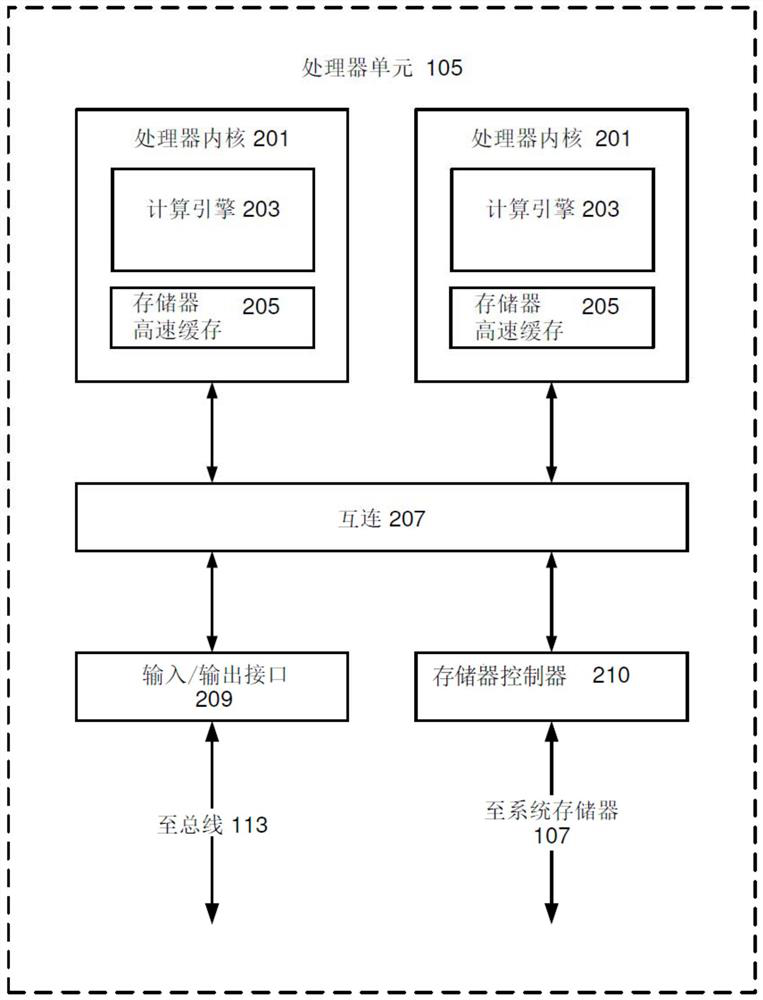

[0017] A computing device, such as a programmable computer, can implement the various examples by executing software instructions. Correspondingly, figure 1 An illustrative example of computing device 101 is shown. As can be s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap