Flue-cured tobacco-sweet potato-mung bean intercropping and rotation planting method

A planting method and intercropping technology, which are applied in the field of intercropping rotation between flue-cured tobacco, sweet potato and mung bean, can solve problems such as inconvenience of operation, and achieve the effects of not wasting land resources, reducing surface evaporation, and utilizing soil nutrients in a balanced manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Tobacco monoculture: the ridge distance is 140cm, the ridge height is 30cm, the tobacco adopts equidistant planting mode, and the plant spacing is 65cm; it is managed according to the conventional cultivation method.

Embodiment 2

[0040] Monocropping sweet potato: the ridge spacing is 90cm, the ridge height is 25cm, and the sweet potato adopts the equidistant planting mode, and the plant spacing is 28cm; it is managed according to the conventional cultivation method.

Embodiment 3

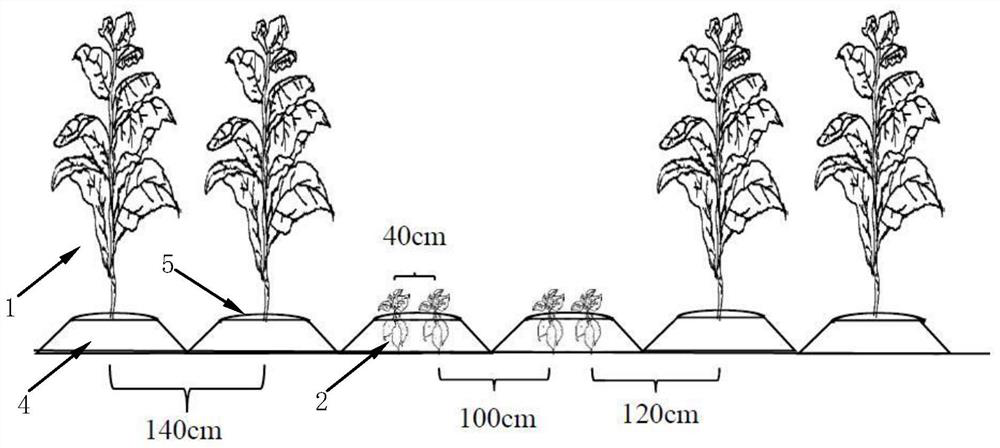

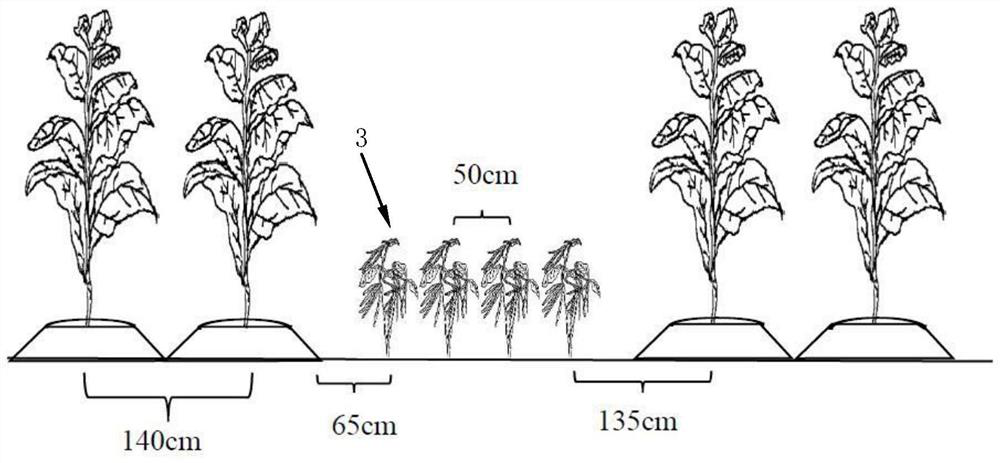

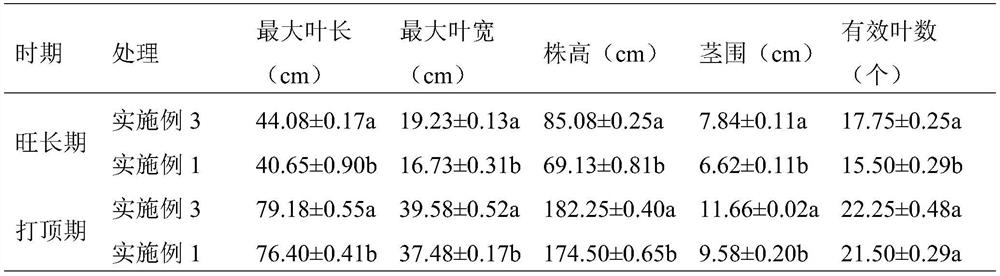

[0042] Flue-cured tobacco-sweet potato-mung bean intercropping planting (detailed method as mentioned above): ridge distance is 140cm, ridge height is 30cm, transplant tobacco and sweet potato according to the mode of two ridges of tobacco, two ridges of sweet potato, two ridges of tobacco, two ridges of sweet potato, each tobacco Plant two rows of sweet potatoes on the ridge, and finally two rows of tobacco and four rows of sweet potatoes. After the sweet potatoes are harvested, level the land and sow mung beans (row sowing). , the spacing between sweet potatoes in the same row of sweet potatoes is 25-30cm, the row spacing of two rows of sweet potatoes in the same tobacco ridge is 40cm, the row spacing of two rows of sweet potatoes in adjacent tobacco ridges is 100cm, and the spacing of mung beans in the same row of mung beans is 15-20cm , the row spacing of adjacent mung beans is 50cm; tobacco, sweet potato and mung beans are managed according to conventional cultivation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com