Tail gas circulating equipment of sleeve lime kiln

A technology of sleeve lime kiln and exhaust gas circulation, which is applied in the fields of dispersed particle filtration, transportation and packaging, and dispersed particle separation, etc., which can solve problems such as failure to meet environmental protection emission requirements, out-of-control NOx, and increased air coefficient in the kiln, and achieve improved catalytic performance. Reduction efficiency and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

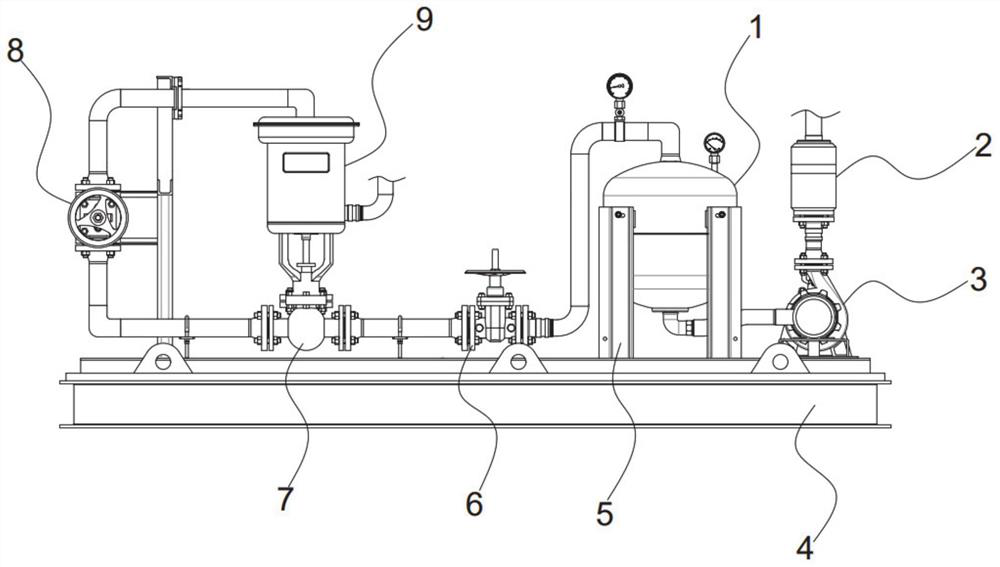

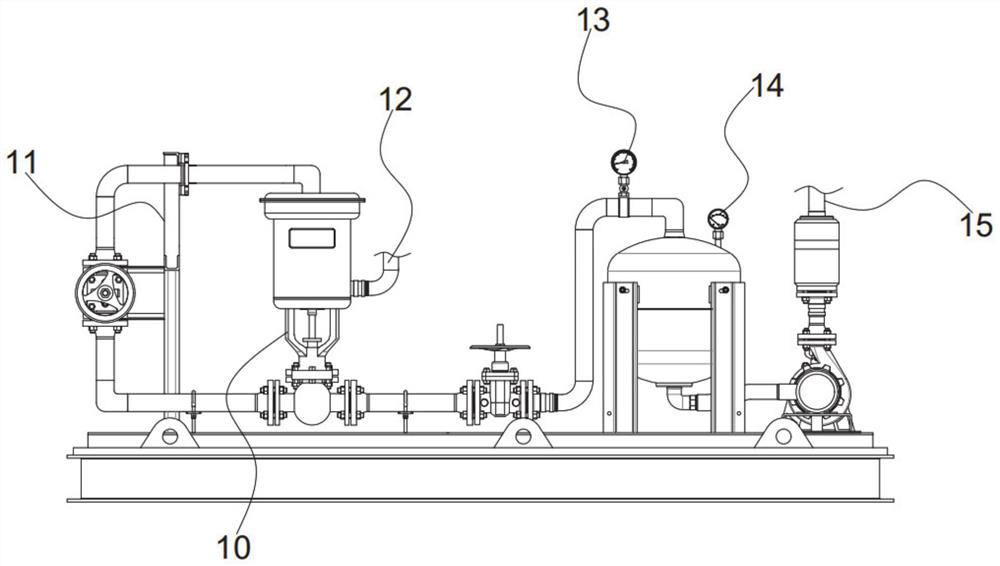

[0031] Example: see attached Figure 1-4 , the present invention provides a technical scheme: a kind of tail gas circulation equipment of a sleeve lime kiln, which comprises:

[0032] base 4;

[0033] The air pump 3, the air pump 3 is fixedly installed on the top surface of the base 4;

[0034] Powder filter 2, the powder filter 2 is arranged above the air suction pump 3, the top port of the powder filter 2 is connected with the exhaust port of the sleeve lime kiln by the air suction pipe 15, and the bottom port of the powder filter 2 is connected with the air suction pump. The top ports of 3 are connected by pipes;

[0035] Cooling tower 1, the cooling tower 1 is fixedly installed on the top surface of the base 4 using the mounting frame 5, and the bottom port of the cooling tower 1 and the left port of the air extraction pump 3 are connected by a pipe;

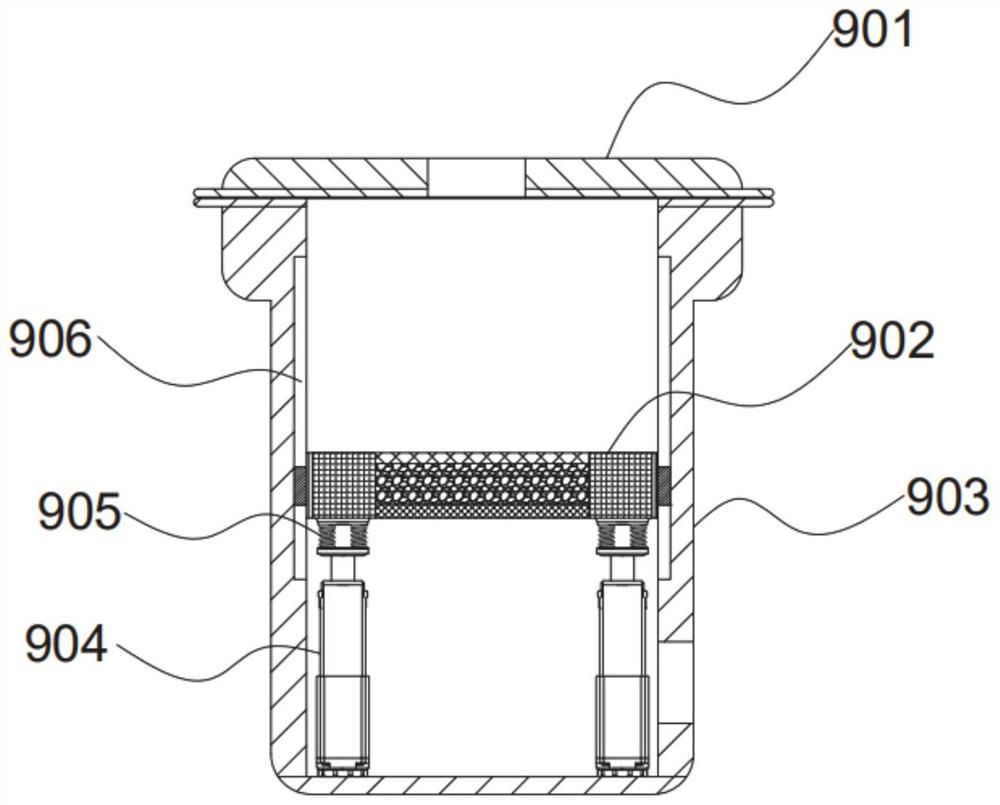

[0036] Gas filter assembly 9, the gas filter assembly 9 is arranged on the pipeline auxiliary mechanism, and the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com