Residue recycling and cleaning device for petroleum coke production and transportation based on circular economy

A cleaning device and technology of petroleum coke, applied in liquid cleaning methods, cleaning methods and utensils, filtration circuits, etc., can solve the problems of incomplete cleaning of impurities, pollution of the surrounding environment, etc., to reduce the difficulty of cleaning, improve environmental protection, Avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

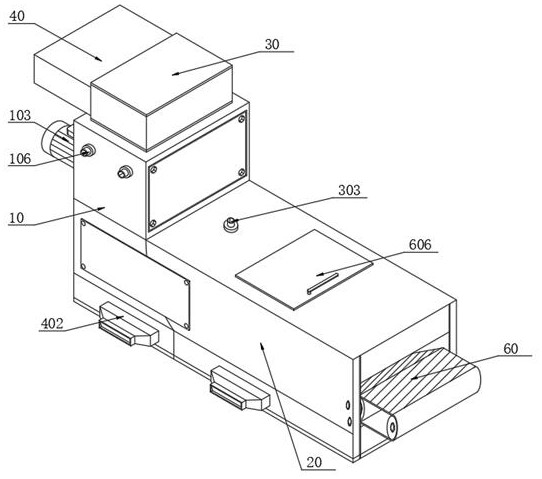

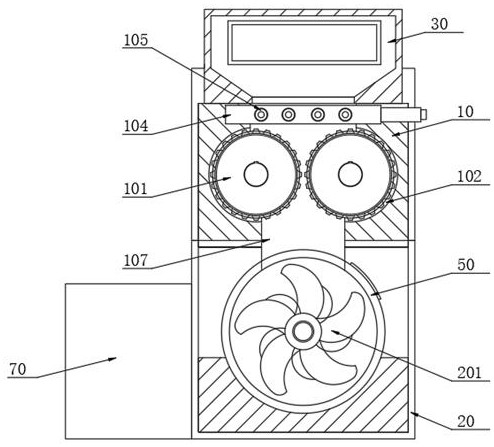

[0033] see Figure 1-2 As shown, a petroleum coke production and transportation residue recovery and cleaning device based on circular economy includes a treatment box 10 and a recovery box 20 below it. The top of the treatment box 10 is provided with a feed hopper 30, and the top of the feed hopper 30 The interior is communicated with a feed pipe 40, the left side of the recovery box 20 is provided with a sieve tube 50, and the right side of the recovery box 20 is provided with a conveyor belt 60, and the back side of the recovery box 20 is provided with a collecting box 70, and the processing box 10 A crushing mechanism is provided inside the crushing mechanism. The crushing mechanism includes a crushing wheel 101. A crushing cavity 102 is provided inside the processing box 10, and two crushing wheels 101 are symmetrically arranged inside the crushing cavity 102. There is a gap between the two crushing wheels 101. In the crushing gap, two crushing wheels 101 are used to crus...

Embodiment 2

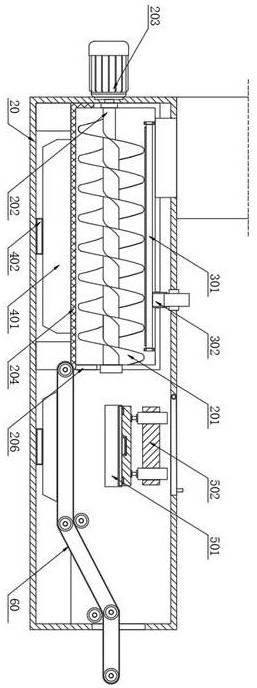

[0037] see Figure 3-4 As shown, in the present invention, the inside of the sieve material drum 50 is provided with a feeding mechanism, wherein the feed mechanism includes a feed impeller 201, and the inside of the sieve material drum 50 is rotatably connected with a rotating shaft 202, and the surface of the rotating shaft 202 and the inside of the feeding impeller 201 Fixedly connected, one end of the rotating shaft 202 runs through the sieve material cylinder 50 and extends to the outside of the sieve material cylinder 50, the left side of the recovery box 20 is provided with a feeding motor 203, and the output shaft of the feeding motor 203 is used to drive the rotating shaft 202 to rotate, and the rotating shaft 202 drives the feeding impeller 201 to rotate inside the sieve barrel 50, and the feeding impeller 201 pushes the crushed material inside the sieve barrel 50 to the right. During the movement of the crushed material to the right, the crushed material with too sma...

Embodiment 3

[0040] see image 3 As shown, the bottom of the movable cover 205 in the present invention is provided with a flushing mechanism, wherein the flushing mechanism includes a flushing pipeline 301, the two ends of the flushing pipeline 301 are fixedly connected to the bottom of the movable cover 205, and the top of the flushing pipeline 301 is communicated with a water guide pipe 302 , by setting the flushing pipe 301 inside the screening cylinder 50, the water guide pipe 302 sends water to the inside of the flushing pipe 301, and when the crushed material is conveyed in a screw in the screening cylinder 50, the flushing pipe 301 flushes the crushed material, crushing Impurities in the material are mixed with waste water and fall out of the inside of the sieve material cylinder 50 through the filter screen 204;

[0041] One end of the water guide pipe 302 runs through the movable cover 205 and extends to the top of the movable cover 205. The top of the recovery box 20 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com