Precise aluminum profile extrusion forming equipment and forming method

A technology of extrusion molding and molding method, which is applied in the field of aluminum profile manufacturing, can solve the problems of low cleaning efficiency and achieve the effects of improving work stability, production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

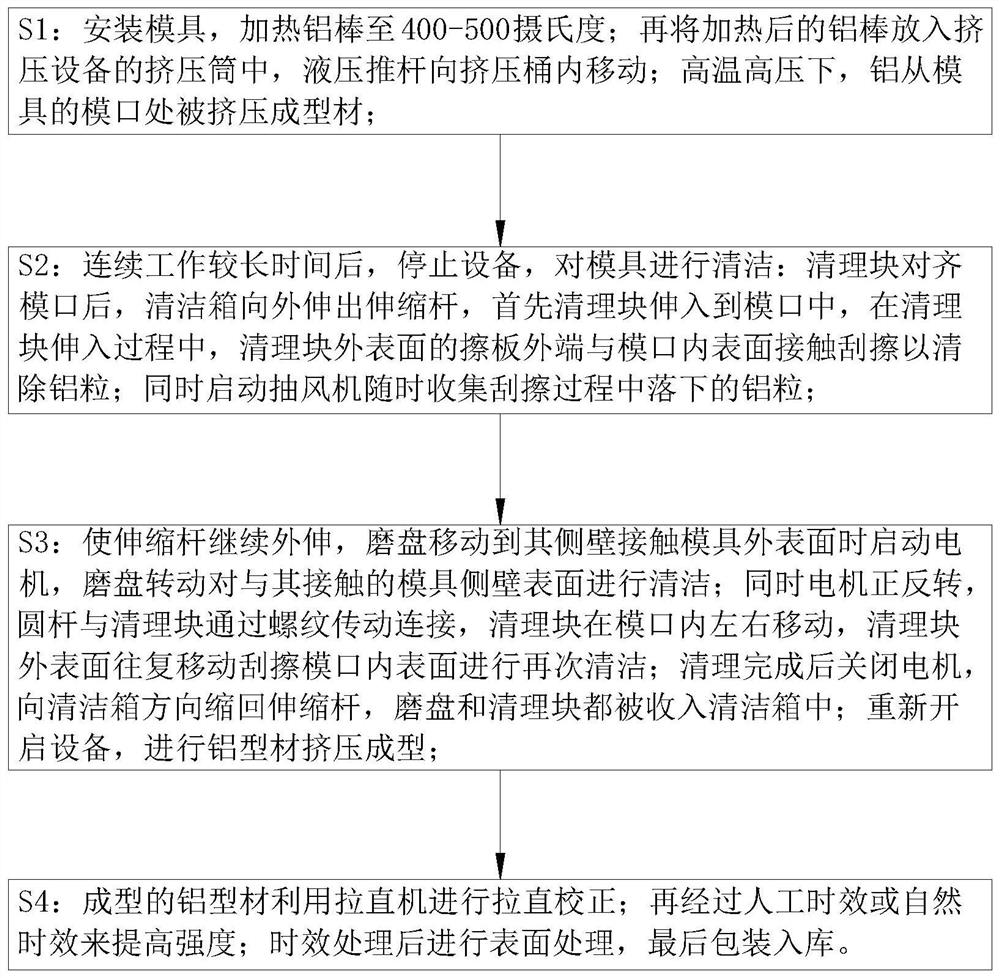

Method used

Image

Examples

Embodiment approach

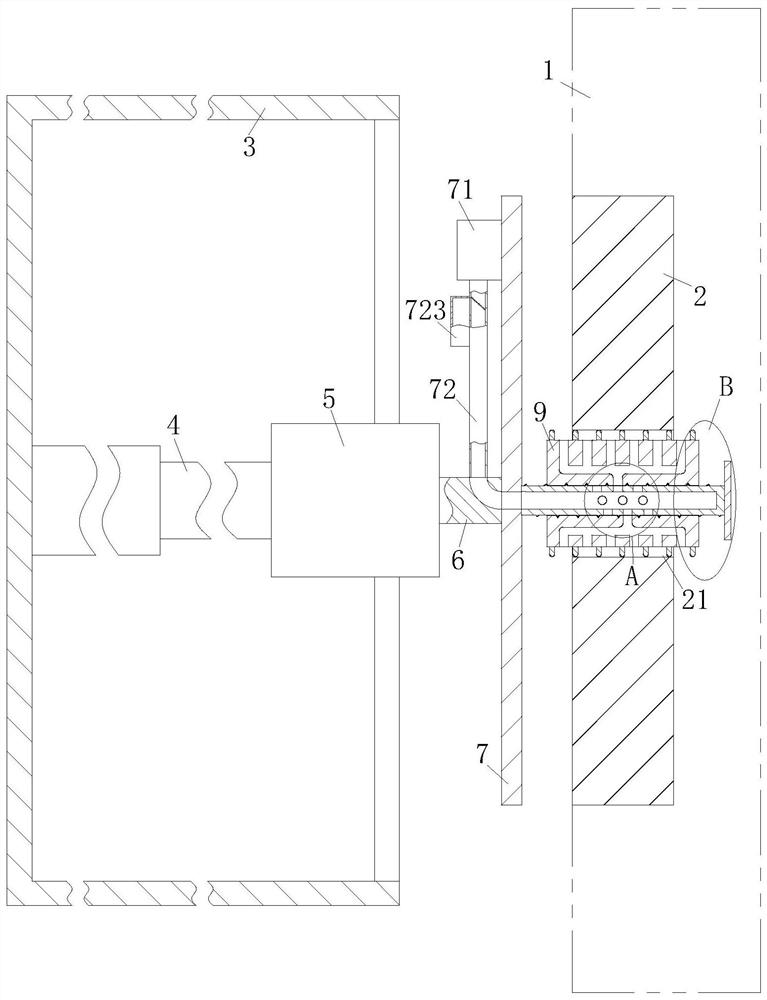

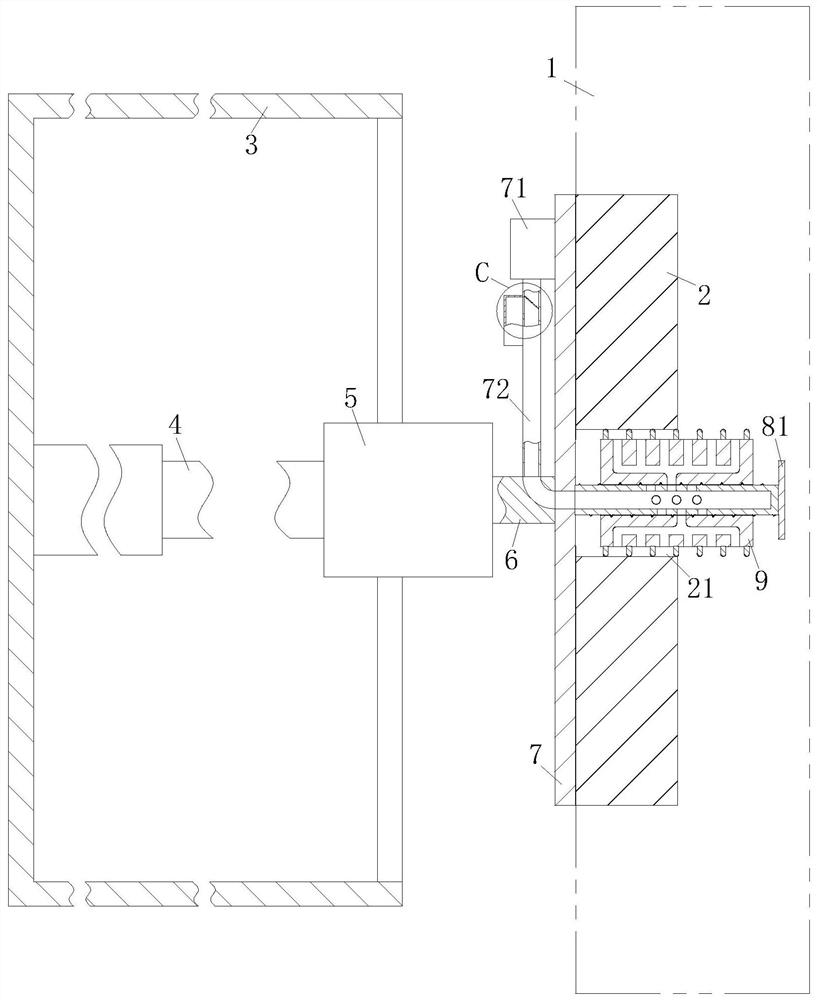

[0051] As an embodiment of the present invention, the exhaust fan 71 is installed at a position close to the edge of the side wall surface of the grinding table 7 .

[0052] During work, since the blower 71 is arranged on the position of the side wall surface of the grinding disc 7 near the edge, the counterweight of the grinding disc 7 is uneven, and when the grinding disc 7 rotates, a large vibration can be caused, and the vibration is transmitted to the cleaning block 9 through the round rod 8, so that The end of the wiping plate 92 also vibrates relative to the mold 2, and the vibration strengthens the scraping force of the wiping plate 92 on the inner surface of the die opening 21, which improves the cleaning efficiency; and the vibration makes the end of the wiping plate 92 and the inner surface of the die opening 21 more energy Intermittent gaps are produced to cooperate with the exhausting effect of the exhaust fan 71 to avoid the situation that some large aluminum part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com