3D weaving path generation method for fused filament manufacturing

A technology of weaving paths and paths, applied in the field of additive manufacturing, to achieve the effect of reducing anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0047] Preferred implementation example of the present invention, in conjunction with accompanying drawing, describe in detail as follows:

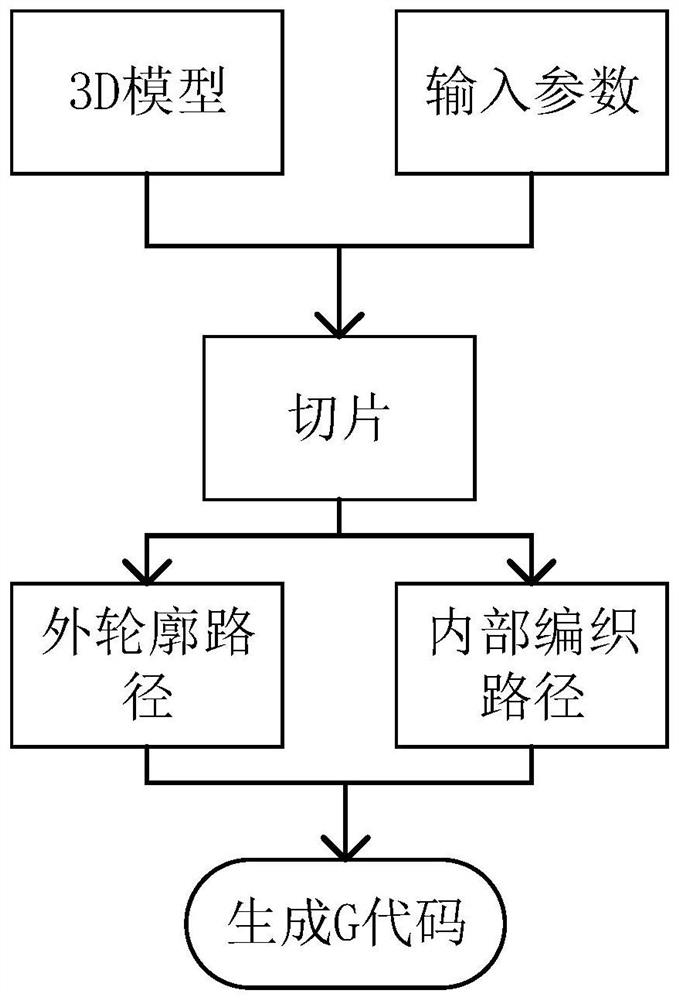

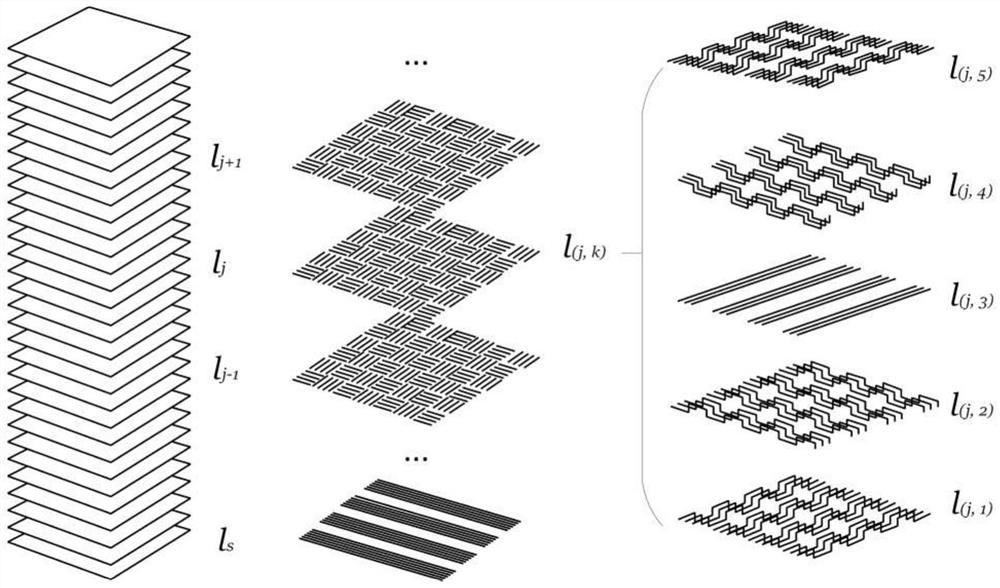

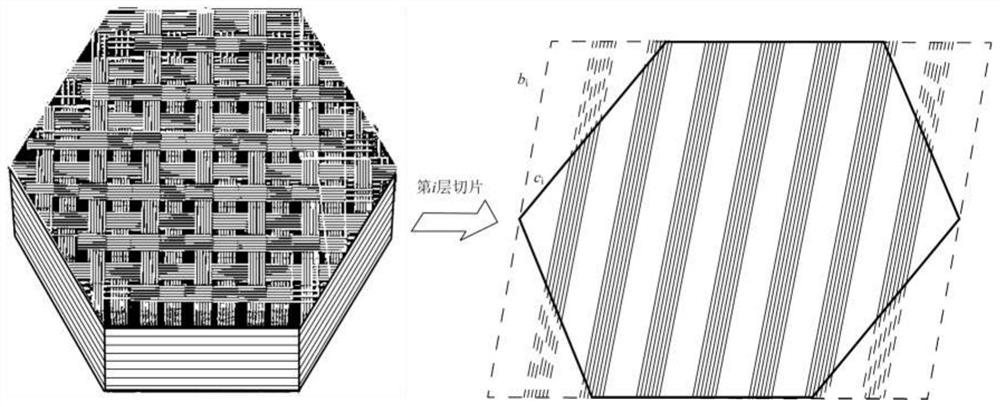

[0048] In this embodiment, the 3D weaving path for fused filament manufacturing includes an inner weaving path and an outer contour path, such as Figure 1-3 As shown, the 3D braiding path generation method for fused filament manufacturing provided in this embodiment includes the following steps:

[0049] (1) Input parameters. The specific operation is to input the surface triangular mesh model (that is, 3D model), layer thickness and weaving control parameters to the 3D printing platform. The programming control parameters include w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com