Preparation method of ecological well rock salt

A well mine salt and ecological technology, applied in the field of ecological mine salt preparation, can solve problems such as non-conformity, and achieve the effects of avoiding adhesion, high product quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

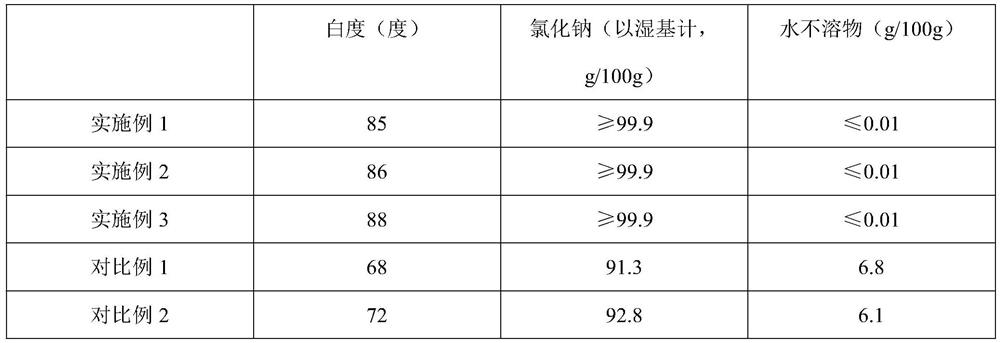

Examples

Embodiment 1

[0029] A kind of preparation method of ecological well mineral salt, concrete steps are as follows:

[0030] (1) First add natural rock salt collected from 1,000 meters underground into the reactor, heat it to 650°C, feed carbon dioxide into the reactor under heat preservation, and discharge the molten material in the reactor through the outlet;

[0031] (2) Then heat to 799° C., feed carbon dioxide into the reactor under heat preservation state, and discharge the molten material in the reactor through the outlet;

[0032] (3) Then be heated to 830 ℃, pass into carbon dioxide in the reaction kettle under the heat preservation state, collect the material of molten state from the outlet of reaction kettle, cool to obtain solid, get 10kg solid and add 120kg water, stir and dissolve, obtain brine;

[0033] (4) Finally, pump the brine into the five-effect evaporator for evaporation and crystallization, and the five-effect discharge volume is 15%, 30%, 45%, 60%, and 50% of the corre...

Embodiment 2

[0042] A kind of preparation method of ecological well mineral salt, concrete steps are as follows:

[0043] (1) First add natural rock salt collected from 1,000 meters underground into the reactor, heat it to 750°C, feed carbon dioxide into the reactor under heat preservation, and discharge the molten material in the reactor through the outlet;

[0044] (2) Then heat to 799° C., feed carbon dioxide into the reactor under heat preservation state, and discharge the molten material in the reactor through the outlet;

[0045](3) Then be heated to 820 ℃, pass into carbon dioxide in the reaction kettle under heat preservation state, collect the material of molten state from the outlet of reaction kettle, cool to obtain solid, get 10kg solid and add in 150kg water, stir and dissolve, obtain brine;

[0046] (4) Finally, pump the brine into the five-effect evaporator for evaporation and crystallization, and the five-effect discharge volume is 15%, 30%, 45%, 60%, and 50% of the corresp...

Embodiment 3

[0055] A kind of preparation method of ecological well mineral salt, concrete steps are as follows:

[0056] (1) First add natural rock salt collected from 1,000 meters underground into the reactor, heat it to 700°C, feed carbon dioxide into the reactor under heat preservation, and discharge the molten material in the reactor through the outlet;

[0057] (2) Then heat to 799° C., feed carbon dioxide into the reactor under heat preservation state, and discharge the molten material in the reactor through the outlet;

[0058] (3) Then be heated to 825 ℃, pass into carbon dioxide in the reactor under heat preservation state, collect the material of molten state from the outlet of reactor, cool to obtain solid, get 10kg solid and add in 140kg water, stir and dissolve, obtain brine;

[0059] (4) Finally, pump the brine into the five-effect evaporator for evaporation and crystallization, and the five-effect discharge volume is 15%, 30%, 45%, 60%, and 50% of the corresponding feed amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com