Crankshaft rotor assembly, compressor and air conditioner

A rotor and crankshaft technology, applied in the field of air conditioning, can solve the problems of high cost, complicated operation, and high machining accuracy of the crankshaft, and achieve the effects of low cost, increased contact area, accurate and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

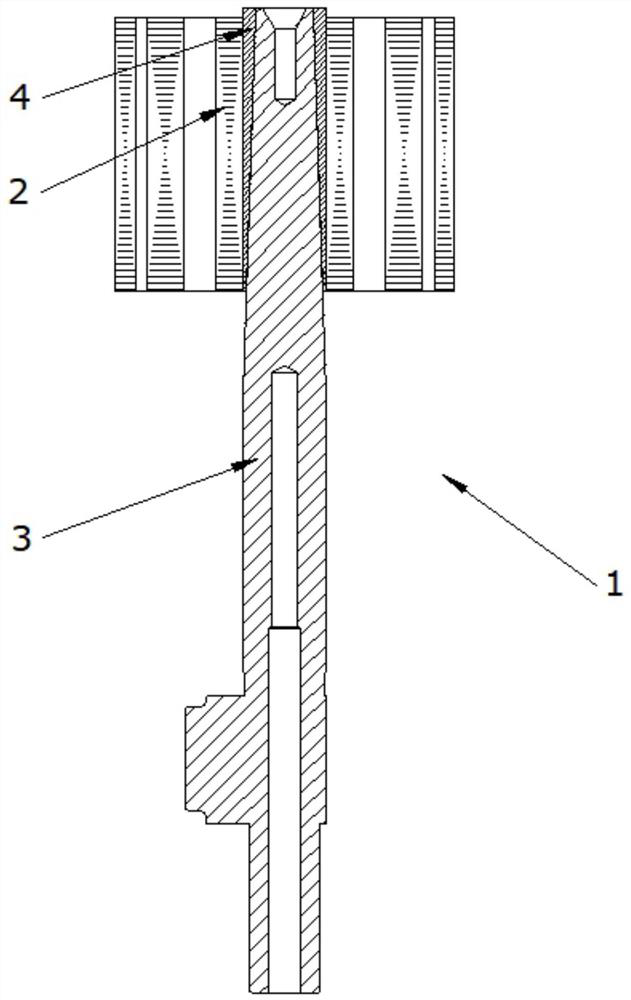

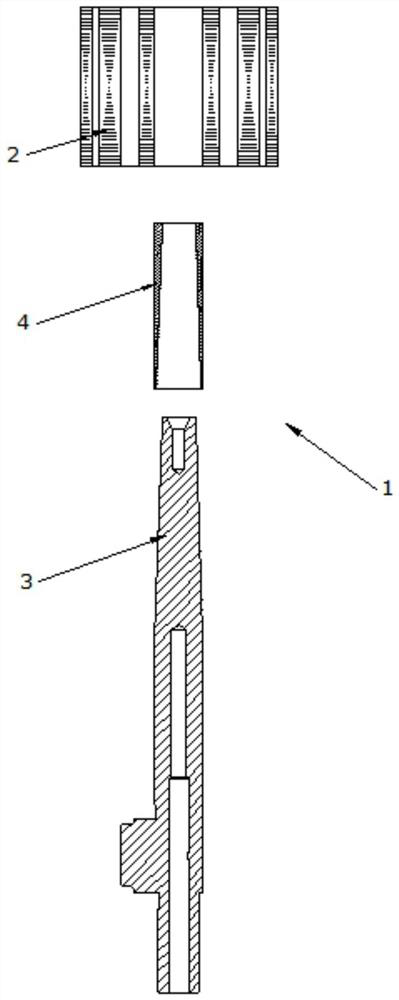

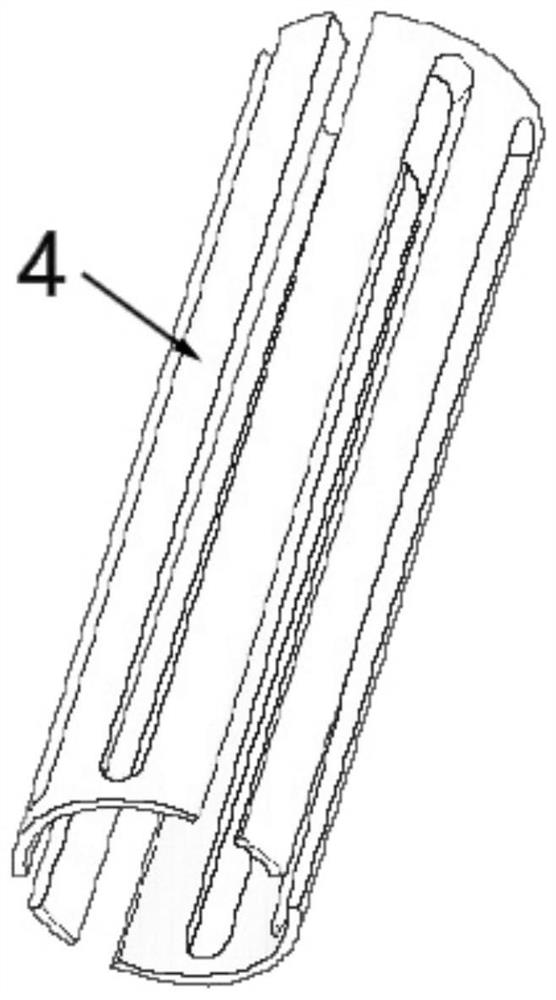

[0052]A crankshaft rotor assembly, including a crankshaft, a rotor and a bushing, the crankshaft includes a long shaft section, the upper part of the long shaft section is a truncated cone, and the inside of the bushing is a truncated cone that fits the truncated cone of the crankshaft , the rotor is provided with a mounting hole, and the bushing is set outside the crankshaft and is interference fit with the mounting hole of the rotor. The frustum of the crankshaft passes through the bushing and is fixedly installed in the installation hole of the rotor. The long axis section of the crankshaft also includes a cylinder, and the cylinder is connected with the truncated cone. The bush is provided with several grooves. The groove body is a U-shaped groove. The U-shaped grooves extend axially and are evenly distributed around the bushing, and the openings of two adjacent U-shaped grooves have different orientations. The mounting hole of the rotor is cylindrical, and the outside ...

Embodiment example 2

[0054] A crankshaft rotor assembly, including a crankshaft, a rotor and a bushing, the crankshaft includes a long shaft section, the upper part of the long shaft section is a truncated cone, and the inside of the bushing is a truncated cone that fits the truncated cone of the crankshaft , the rotor is provided with a mounting hole, and the bushing is set outside the crankshaft and is interference fit with the mounting hole of the rotor. The frustum of the crankshaft passes through the bushing and is fixedly installed in the installation hole of the rotor. The long axis section of the crankshaft also includes a cylinder, and the cylinder is connected with the truncated cone. The bush is provided with several grooves. The groove body is a U-shaped groove. The U-shaped grooves extend axially and are evenly distributed around the bushing, and the openings of two adjacent U-shaped grooves have different orientations. The mounting hole of the rotor is cylindrical, and the outside...

Embodiment example 3

[0056] A crankshaft rotor assembly, including a crankshaft, a rotor and a bushing, the crankshaft includes a long shaft section, the upper part of the long shaft section is a truncated cone, and the inside of the bushing is a truncated cone that fits the truncated cone of the crankshaft , the rotor is provided with a mounting hole, and the bushing is set outside the crankshaft and is interference fit with the mounting hole of the rotor. The frustum of the crankshaft passes through the bushing and is fixedly installed in the installation hole of the rotor. The long axis section of the crankshaft also includes a cylinder, and the cylinder is connected with the truncated cone. The bush is provided with several grooves. The groove body is a U-shaped groove. The U-shaped grooves extend axially and are evenly distributed around the bushing, and the openings of two adjacent U-shaped grooves have different orientations.

[0057] The installation hole of the rotor is in the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com