Multi-point type flexible thermocouple probe tube with parallel positive electrode hot ends for heating furnace

A thermocouple and multi-point technology, applied in the direction of thermometers using electric/magnetic elements that are directly sensitive to heat, using electrical devices, using electromagnetic means, etc., can solve the needs of installation convenience and wiring that cannot meet the volume requirements Complicated, time-consuming installation and other issues, to achieve the effect of high adaptability, small size, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

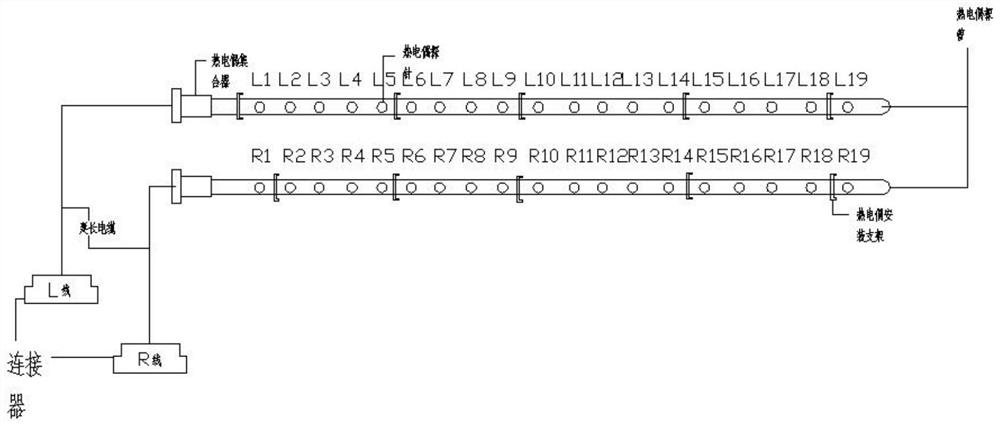

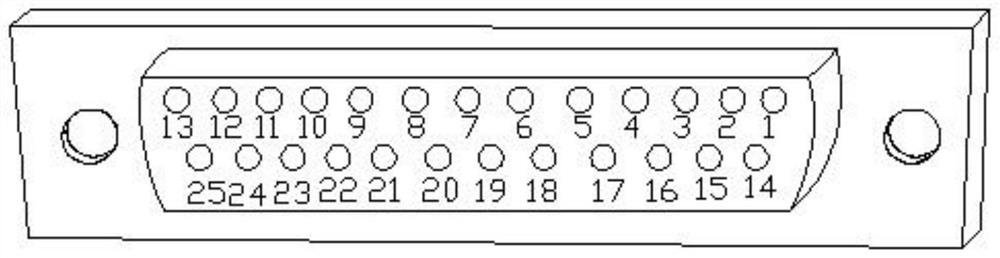

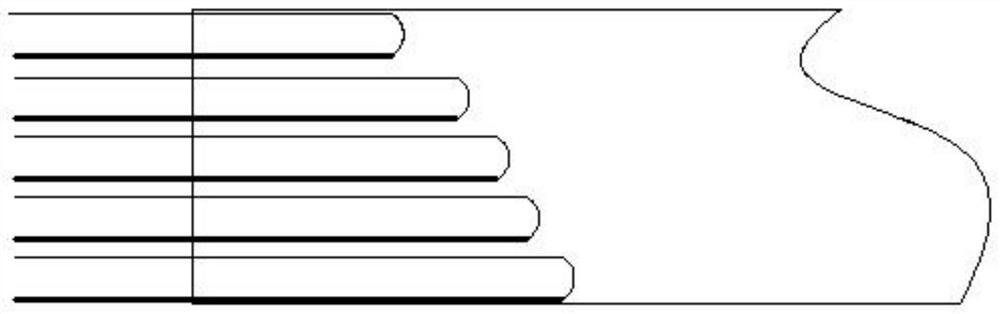

[0017] see Figure 1-3 , according to an embodiment of the present invention, a multi-point flexible thermocouple probe tube for parallel connection of the positive hot end of a heating furnace, including a thermocouple collector, a thermocouple probe tube, a thermocouple probe, an extension cable and a connector, The thermocouple assembly is composed of 19 thermocouples with the largest number of thermocouples in the smallest cross-section. It is a total of 38 thermocouples with glass fibers of 0.25mm (or other sizes) with positive and negative poles (positive and negative poles) Each 19) metal wires are assembled in a corrosion-resistant stainless steel with a diameter of less than 6mm and a length of 10mm (or other sizes) of stainless steel sleeves (the thickness of the stainless steel sleeve is 1mm or other sizes), so that the thermocouple can The distance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com