Low-carbon steel and manufacturing method for improving performance uniformity of low-carbon steel rolled by CSP process ferrite

A manufacturing method and low-carbon steel technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as edge waves in the galvanizing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

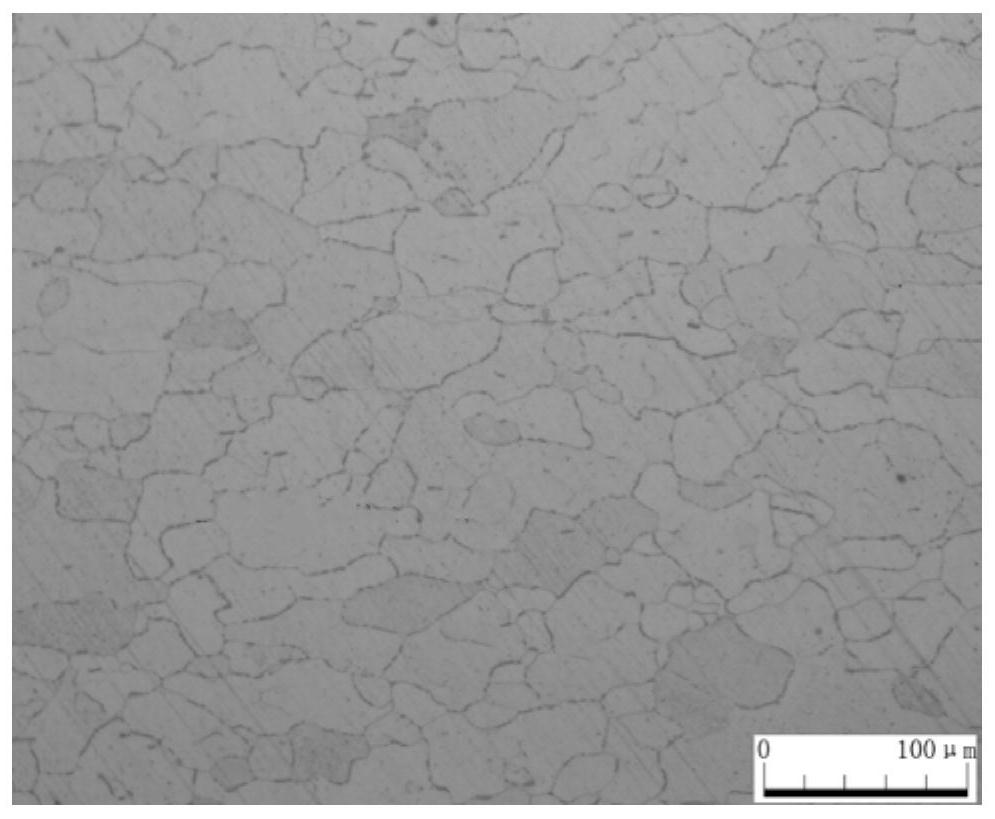

[0030] A manufacturing method for improving the performance uniformity of ferritic rolled low-carbon steel in a CSP process, the chemical composition and weight percentage content of the low-carbon steel are: C: ≤0.070%, Si: ≤0.050%, Mn: 0.08-0.30 %, P: ≤0.025%, S: ≤0.015%, Als: 0.020-0.060%, and the rest are Fe and unavoidable inclusions. The specific component contents of each embodiment are shown in Table 1, and the balance not shown in Table 1 is Fe and unavoidable inclusions.

[0031] The manufacturing method is as follows: converter smelting, LF furnace refining, continuous casting, heating, rolling, laminar cooling, and coiling.

[0032] The process control is:

[0033] 1) For smelting and continuous casting, converter smelting and LF furnace refining shall be carried out according to the ingredients in the above requirement 1, and the vibration curve shall adopt the principle of high frequency and low amplitude; and continuous casting into billets with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

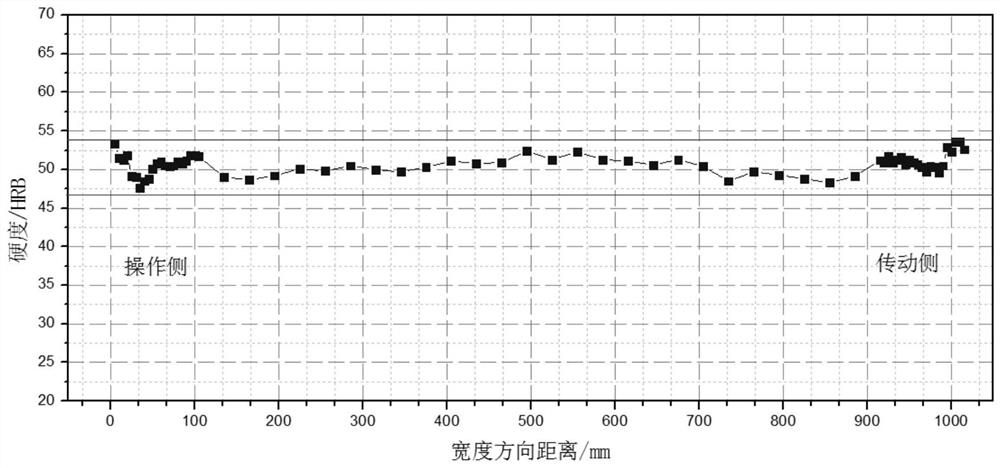

| Hardness | aaaaa | aaaaa |

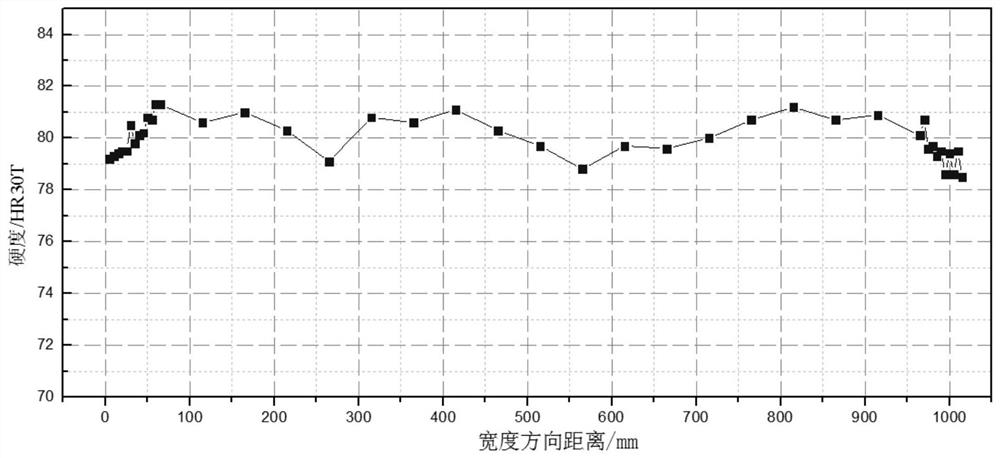

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com