Application method of protective coating in glass hot bending process

A technology of protective coating and application method, applied in applications, household utensils, inks, etc., can solve problems such as shortened service life of molds, low yield rate, mold indentation, etc., to achieve extended service life, high hardness, and excellent adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

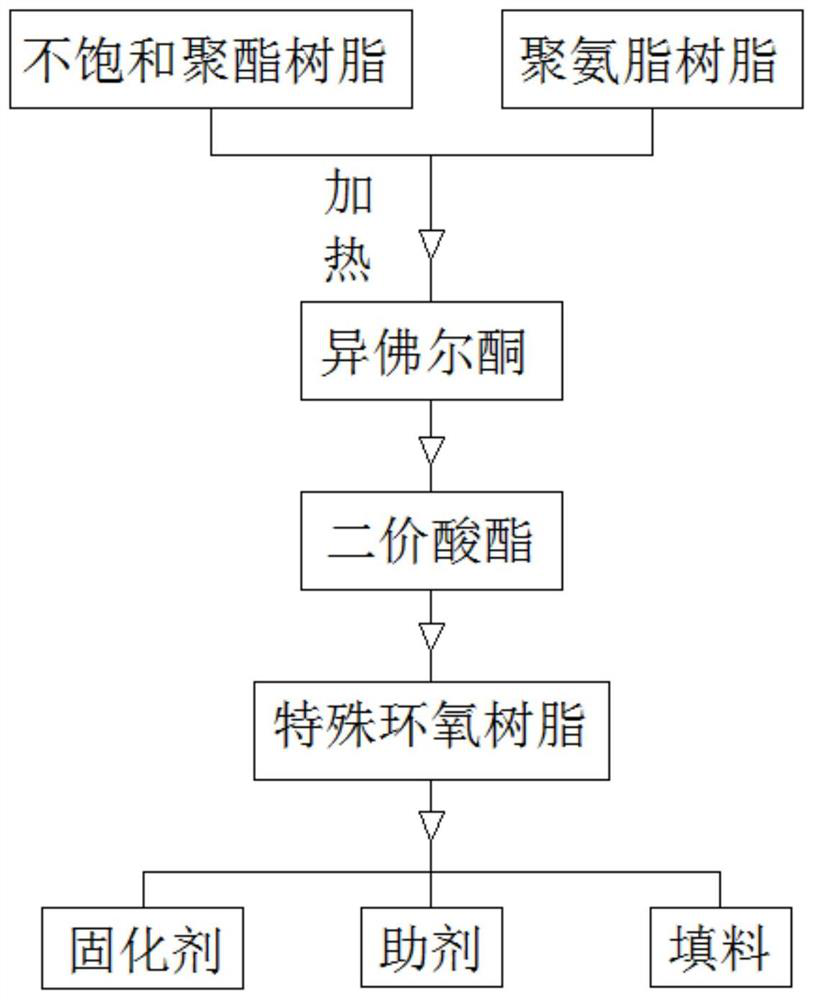

[0018] 1. The protective coating in the hot bending process of glass is made of unsaturated polyester resin, polyurethane resin, isophorone, dibasic ester, special epoxy resin, curing agent, auxiliary agent and filler;

[0019] 2. The mass percentage of each component is as follows: unsaturated polyester resin 20-30%, polyurethane resin 25-35%, isophorone 15-18%, divalent ester 18-20%, special epoxy resin 20%, curing agent 6-8%, auxiliary agent 1-2%, filler 5-10%;

[0020] 3. Pour the unsaturated polyester resin and polyurethane resin into the container, heat it, stir it continuously during the heating process, so that it can be fully mixed, and stop heating after heating to 80 °C;

[0021] 4. Add isophorone and dibasic acid ester to the heated and stirred mixture, use a mixer to stir slowly for 5 minutes to make a mixed solvent, and keep heating during the stirring process to keep the temperature at 80°C;

[0022] 5. Gradually add the special epoxy resin to the mixed solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com