Room-temperature-curing solvent-free anti-doodling coating

A room temperature curing, solvent-free technology, applied in the direction of coating, etc., can solve the problem of easy separation of fluorine and silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

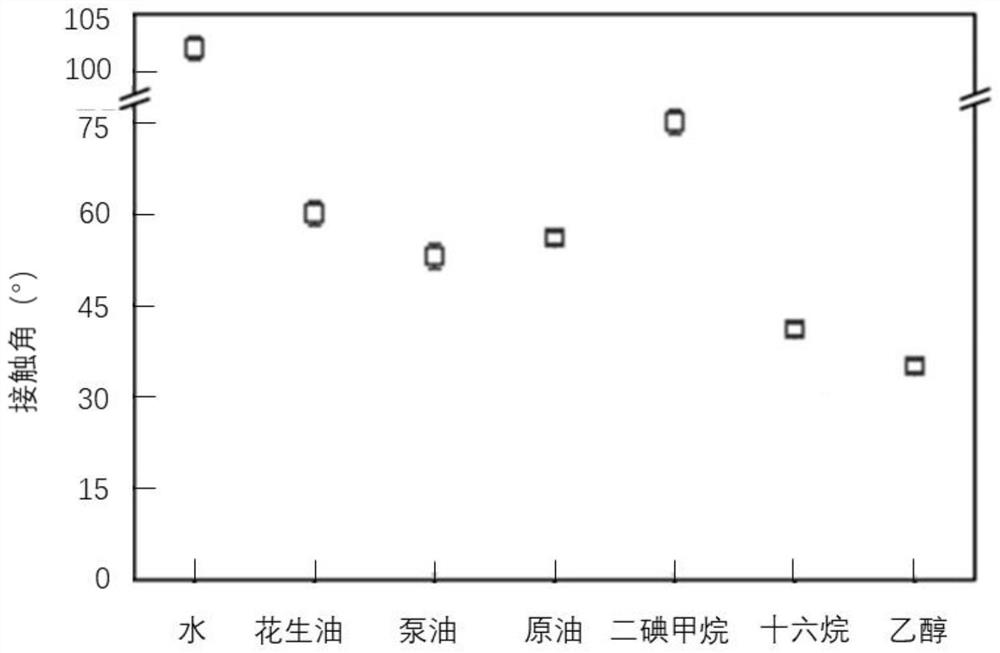

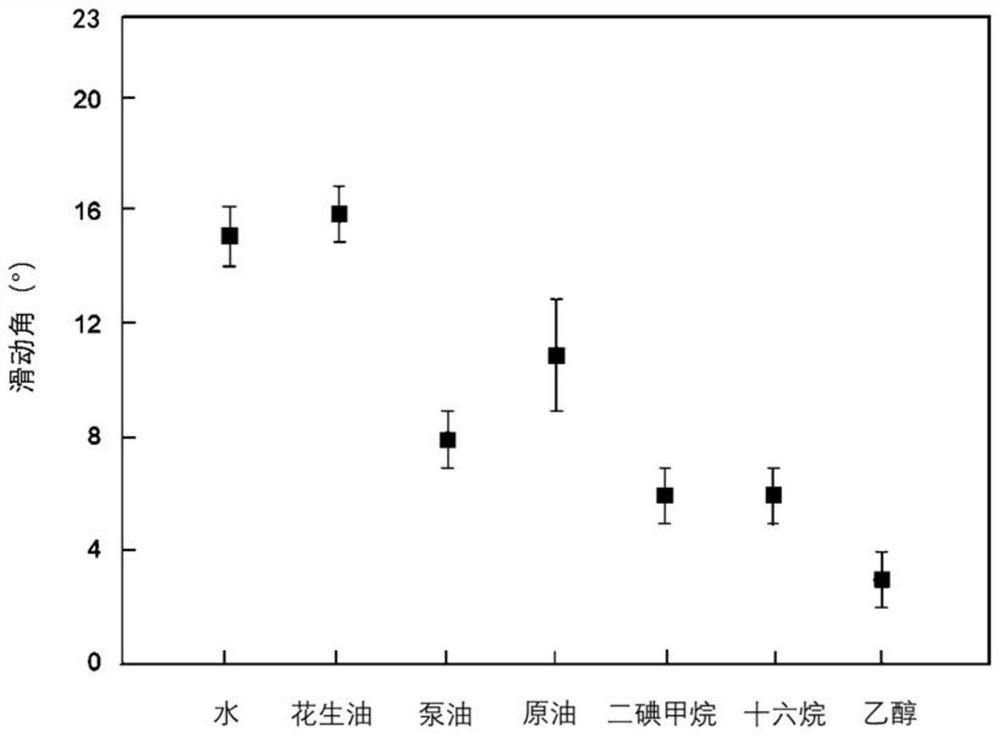

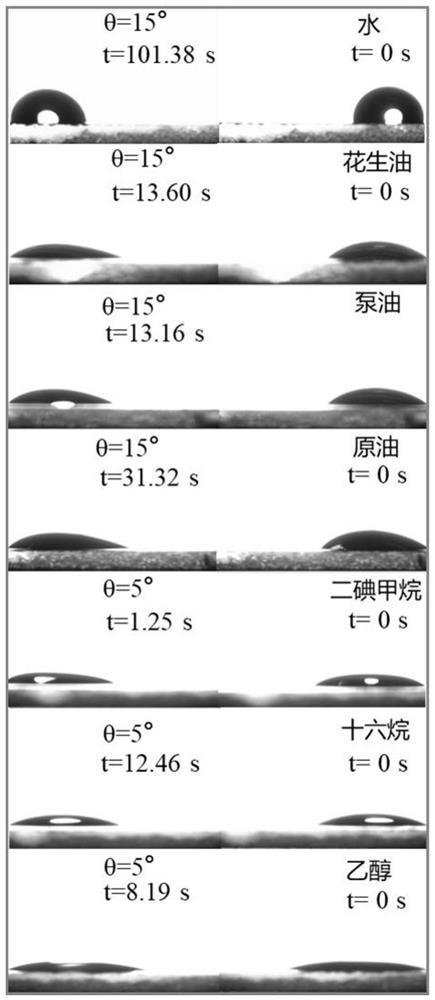

[0051] 1, take water, peanut oil, pump oil, crude oil, diiodomethane, n-hexadecane and ethanol as measuring liquid respectively, measure the contact angle and sliding angle of different liquids on the anti-graffiti coating described in embodiment 1, contact angle The required test liquid is 2 μL, and the test liquid required for the sliding angle is 20 μL. For the measurement results, see the attached Figure 1-3 , as can be seen from the figure, the contact angles of water, peanut oil, pump oil, crude oil, diiodomethane, n-hexadecane and ethanol on the anti-graffiti coating are all below 105°, and the sliding angle is suitably below 20°, even The sliding angle of ethanol on the coating is below 5°, and below 15°, these liquids can slide off quickly in a short time, so as to achieve the effect of antifouling and antigraffiti.

[0052] When dihydroxy-terminated hydroxysilicone is covalently linked into the network, it does not behave as a liquid at the macroscopic level, but st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com