Microwave heating film device and system

A technology of microwave heating and thin film, which is applied in the direction of microwave heating to achieve the effects of avoiding leakage, improving heating efficiency and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

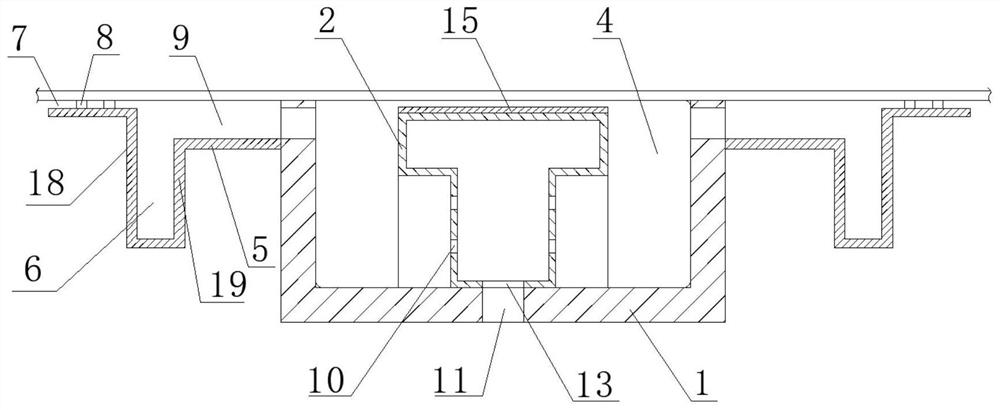

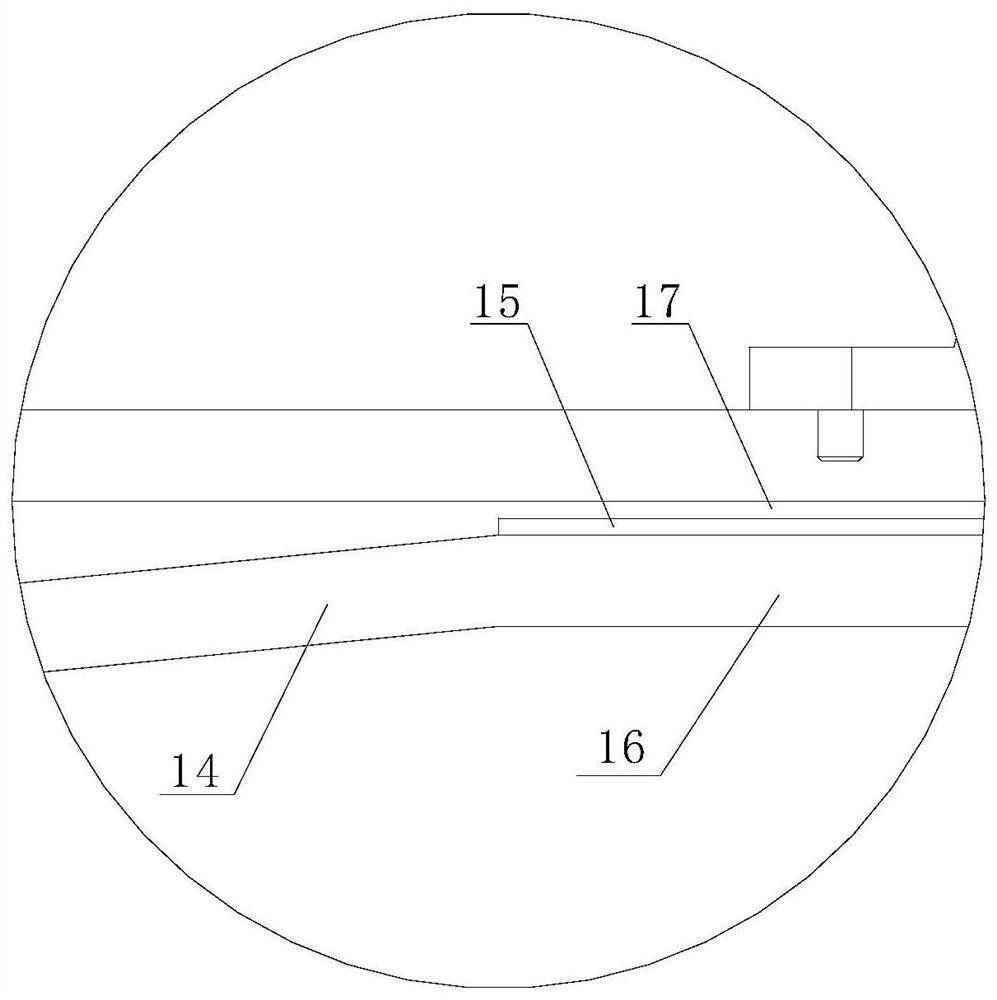

[0034] Such as Figure 1-4 As shown, a microwave heating film device, the heating device includes a rectangular waveguide 1 and a compression ridge 2, the compression ridge 2 is arranged in the cavity 4 of the rectangular waveguide 1, and a dielectric plate 15 is arranged on the compression ridge 2 , the dielectric plate 15 is a dielectric plate with a high dielectric constant. In the present embodiment, the dielectric constant of the dielectric plate 15 is greater than 3.6. In the present embodiment, the dielectric plate 15 is a cuboid structure, preferably 99% Corundum, the compressed ridge 2 is separated from the film to be heated to form a gap 17, the electromagnetic wave passes through the gap 17 after being compressed by the compressed ridge 2, and heats the lossy dielectric film attached to the metal surface; The rectangular waveguide 1 is provided with an anti-leakage device, so as to prevent the electromagnetic waves at the gap 17 from leaking to the outside, and the ...

Embodiment 2

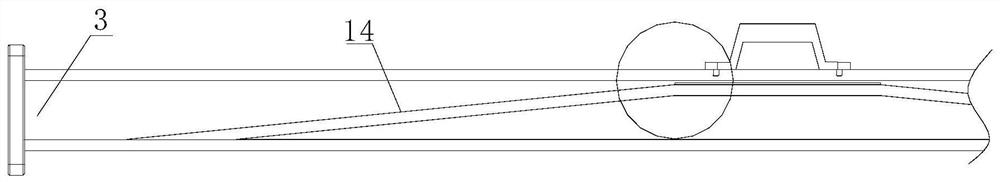

[0043] Considering the low energy utilization rate of the ridge waveguide heating film, multiple heating chambers can be set in a heating device to make full use of microwave energy. A film heating system, such as Figure 5 As shown, a plurality of film heating devices according to the above-mentioned embodiment are provided. In order to uniformly heat the film, generally an even number of parallel film heating devices are provided, and several rectangular waveguides 1 are connected end to end through 90° turning waveguides 21 to form an "S" shape. The heating system of the structure, several said compression ridges 2 are arranged in the same row so that the films to be heated pass through the compression ridges 2 one by one, that is, the moving direction of the film to be heated is perpendicular to the film heating device, and the films are heated from several films one by one. The heating system includes a microwave inlet 3 and a microwave receiving end 22.

[0044] The micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com