Plate grooving machine

A slotting machine and plate technology, which is applied to metal processing machinery parts, metal sawing equipment, driving devices, etc., can solve the problems of difficulty in adjusting the correct inclination angle of the driven wheel, large groove depth error, and frequent replacement of the driven wheel, etc. Easy maintenance and replacement, long service life and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

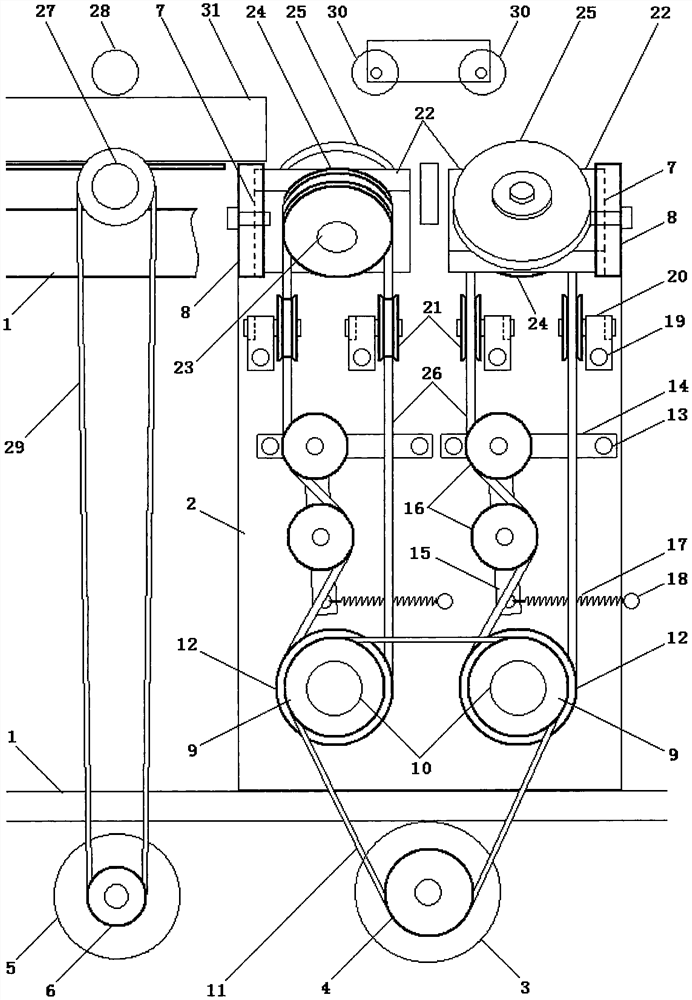

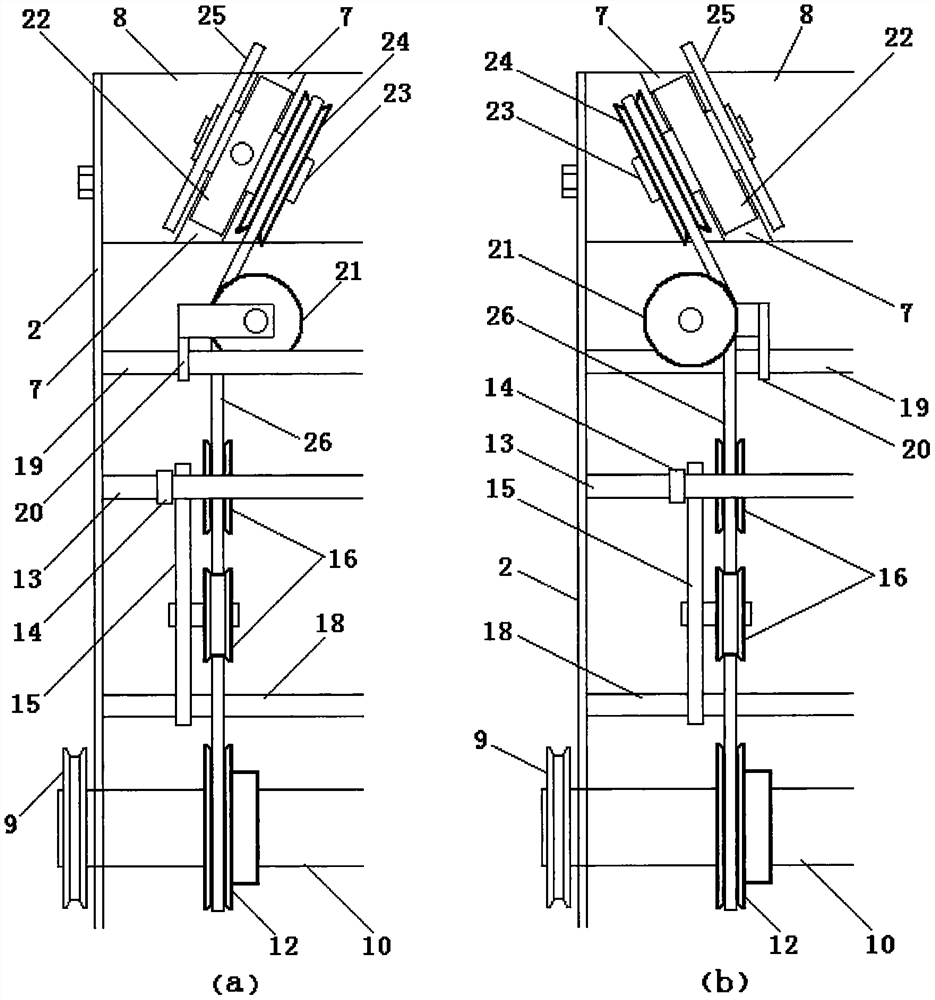

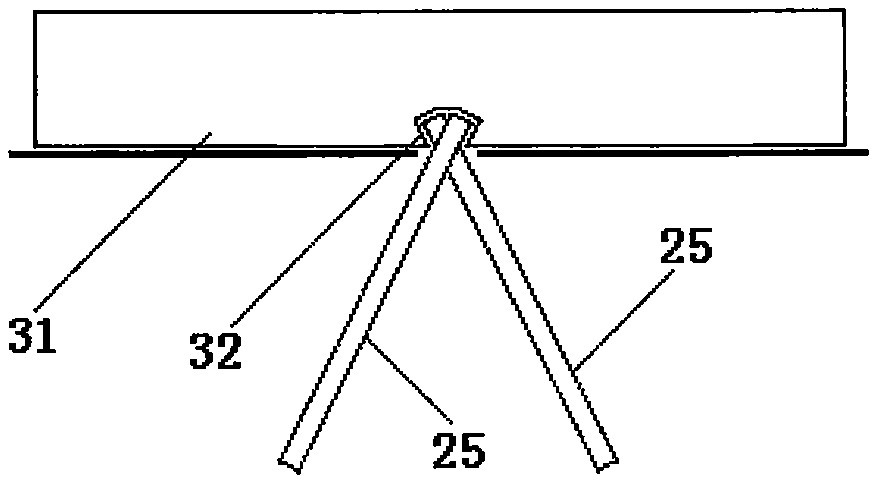

[0026] Example 1: Combining figure 1 , figure 2 , during slotting, the slotting motor 3 and the plate-feeding motor 5 start, and drive the driving wheel 9 of the front and rear two sets of slotting devices and the lower sheave 12 on the driving wheel 9 to rotate coaxially through the toothed belt 11, and the lower groove The wheel 12 drives the upper sheave 24 and the circular saw blade 25 to rotate coaxially through the transmission belt 26. At the same time, the tension springs 17 of the front and rear two sets of slotting devices have been pulling the movable wheel frame 15 to keep the tension wheel 16 in an elastic tension state. , so that the drive belt 26 will not slip due to slack and lose rotation, and the reversing wheels 21 of the front and rear slotting devices keep the upper sheave 24 and the circular saw blade 25 in the normal rotation in the inclined state; then put the plate 31 and the grooving face is sent to the grooving station by the lower roller 27 and th...

Embodiment 2

[0027] Embodiment 2: the processing of plates 31 with different groove depths can be realized by adjusting the circular saw blades 25 of different diameters; height; because the present invention adopts the lower slotting scheme and replaces the ordinary circular saw blade with a milling cutter, it can also ensure consistent groove depth and smooth edges when processing plates with obvious thickness errors.

Embodiment 3

[0028] Embodiment 3: The number of slotting units is correspondingly increased or decreased according to the number of slots on each plate 31; when it is necessary to slot on both sides of the plate 31, the slots on both sides should be staggered to avoid opening on the same parallel line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com