Method for preparing barium carbonate and strontium carbonate through microorganism mineralization

A technology based on barium carbonate and microorganisms, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of strong practicability, uniform dispersion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

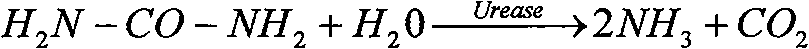

Method used

Image

Examples

Embodiment 1-8

[0042] A kind of microbial mineralization prepares the method for barium carbonate, comprises the following steps:

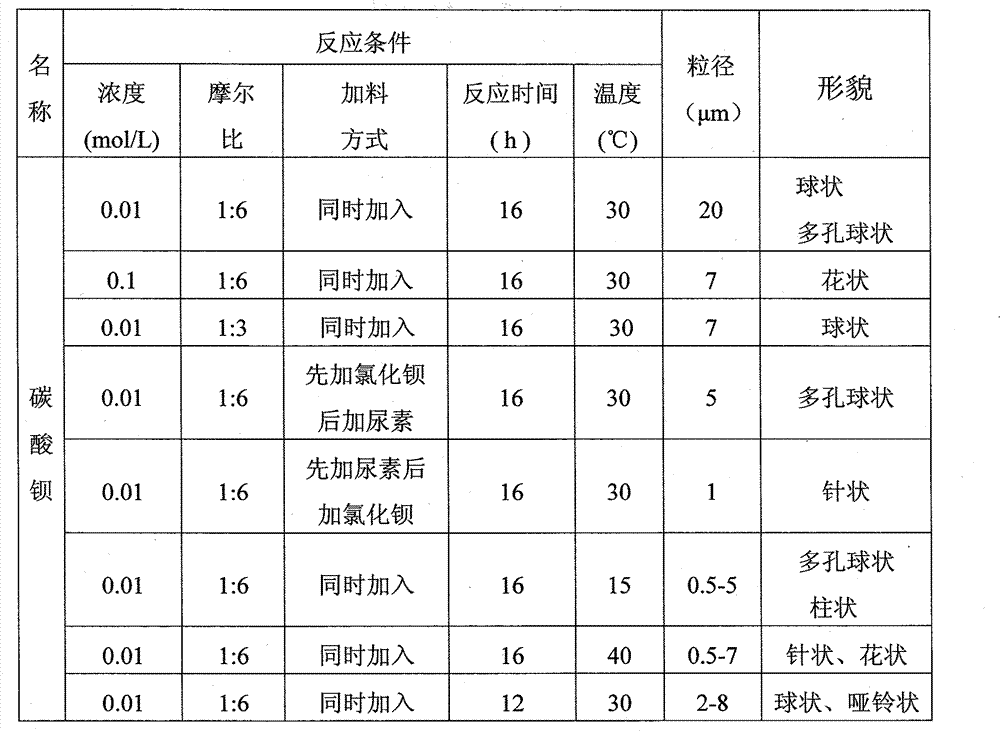

[0043] Prepare the culture medium of microorganism Bacillus pasteurianus and prepare the culture solution containing Bacillus pasteurianus: take 15g of peptone, 5g of NaCl, 1L of distilled water, mix them evenly to form a culture medium and distribute them into conical flasks (such as 250ml conical flasks) 1. Obtain sterilized nutrient solution after high-temperature sterilization; get a Erlenmeyer flask with sterilized nutrient solution, inoculate it with Bacillus Pasteurella, and put the seeds (being Bacillus Pasteurella) into the shaker In the bed (or other equipment in the prior art), at a temperature of 30°C and a rotating speed of 200r / min, cultivate for 12h; get 10ml of the cultured Bacillus pasteurian seed solution and inject it into 100ml of sterilized culture solution , expand the culture in a shaker for 35h (at a temperature of 30°C and a rotating spe...

Embodiment 9-10

[0051] A kind of microbial mineralization prepares the method for barium carbonate, comprises the following steps:

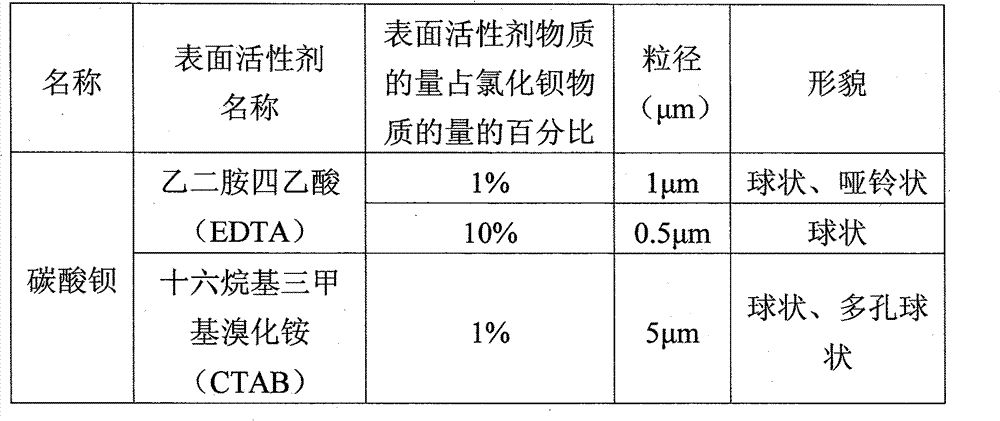

[0052] The cultivation of Bacillus pasteurianus was as in Example 1-8. After the Bacillus pasteurianum was expanded and cultivated for 35h, the barium chloride of 0.01mol / L, urea solution and 0.292g surfactant ethylenediaminetetraacetic acid (EDTA) were added to the above culture solution containing the Bacillus pastereuii simultaneously, The molar ratio of barium chloride to urea solution is 1:6, the reaction temperature is 30°C, and the rotation speed is 200r / min. After 16 hours of reaction, the barium carbonate powder is obtained by aging, washing, filtering and drying, which is spherical and has a particle size of about 3 μm. The powder has complete shape, uniform distribution and no agglomeration. Adding different surfactants and controlling the dosage, the particle size and shape of the barium carbonate powder are different, as shown in Table 2.

[0053...

Embodiment 11

[0056] A kind of microbial mineralization prepares the method for barium carbonate, comprises the following steps:

[0057] The first step, ingredients: get the culture fluid (that is, contain the culture fluid of the bacillus pasturella after cultivation) that has been inoculated with Bacillus pasteurianum after cultivation, take the ratio of adding 0.001mol barium chloride by 1L of this culture fluid Barium chloride, by barium chloride: the ratio of the amount of substance (mol) of urea is to get urea in the ratio of 1: 1;

[0058] The second step, mineralization reaction: according to the order of adding barium chloride first and then adding urea, barium chloride and urea are added to the culture solution inoculated with Bacillus pasturella and cultivated at 10°C. Under the temperature, stir reaction 54h, obtain the post-reaction material that has barium carbonate;

[0059] The third step, aging and post-treatment: after the reacted material containing barium carbonate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com