Feather low-damage rinsing process

A low-damage, feather technology, applied in the field of feather processing, can solve the problems of affecting the use effect and mechanical damage of feathers, and achieve the effect of reducing quality, small damage and avoiding mechanical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

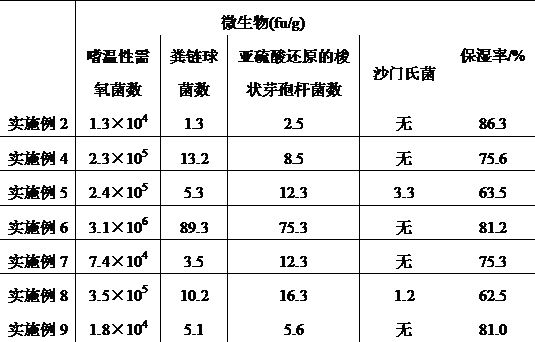

Examples

Embodiment 1

[0038] A low-damage rinsing process for feathers, comprising the following steps:

[0039] (1) Ultrasonic fumigation treatment:

[0040] The feather was placed on the loess stone, and then placed on the steam for fumigation treatment, treated for 10 minutes, and ultrasonically treated during the fumigation treatment. The frequency of the ultrasonic wave was 40kHz, and it was taken out for use after completion;

[0041] (2) Liquid nitrogen spray:

[0042] Evenly spraying liquid ammonia onto the surface of the feathers after ultrasonic fumigation in step (1);

[0043] (3) Shake cleaning treatment:

[0044] The feathers sprayed with liquid nitrogen in step (2) are placed in a constant temperature cleaning solution, and then placed on a shaking table for shaking and cleaning treatment. The shaking speed of the shaking table is controlled to be 80 ° C, and the temperature in the cleaning solution is maintained during the shaking process. The temperature is 50 °C, after shaking f...

Embodiment 2

[0049] A low-damage rinsing process for feathers, comprising the following steps:

[0050] (1) Ultrasonic fumigation treatment:

[0051] The feathers were placed on the loess stone, then placed on the steam for fumigation treatment, treated for 13 minutes, and ultrasonically treated during the fumigation treatment, the frequency of the ultrasonic wave was 60kHz, and taken out for use after completion;

[0052] (2) Liquid nitrogen spray:

[0053] Evenly spraying liquid ammonia onto the surface of the feathers after ultrasonic fumigation in step (1);

[0054] (3) Shake cleaning treatment:

[0055] The feathers sprayed with liquid nitrogen in step (2) are placed in a constant temperature cleaning solution, and then placed on a shaking table for shaking and cleaning treatment, and the shaking speed of the shaking table is controlled to be 85 ° C, and the temperature in the cleaning solution is maintained during the shaking process. The temperature is 55 °C, after shaking for 10...

Embodiment 3

[0060] A low-damage rinsing process for feathers, comprising the following steps:

[0061] (1) Ultrasonic fumigation treatment:

[0062] The feathers were placed on the loess stone, then placed on the steam for fumigation treatment, treated for 16 minutes, and ultrasonically treated during the fumigation treatment. The frequency of the ultrasonic wave was 80kHz, and after completion, it was taken out for use;

[0063] (2) Liquid nitrogen spray:

[0064] Evenly spray the liquid ammonia onto the surface of the feathers after ultrasonic fumigation in step (1);

[0065] (3) Shake cleaning treatment:

[0066] The feathers sprayed with liquid nitrogen in step (2) are placed in a constant temperature cleaning solution, and then placed on a shaking table for shaking and cleaning treatment, and the shaking speed of the shaking table is controlled to be 90 ° C, and the temperature in the cleaning solution is maintained during the shaking process. The temperature is 60°C, after shaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com