Concrete pouring method for large steel ladle reinforced concrete protective door

A reinforced concrete and protective door technology, which is applied in the direction of buildings, door leaves, windows/doors, etc., can solve the problems affecting the appearance quality of steel-laden reinforced concrete protective doors, affecting the overall force of steel-laden reinforced concrete protective doors, and the combination of steel plates and concrete is not compact, etc. problems, to achieve the effect of strengthening the construction quality of filling, avoiding dryness and cold joints, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

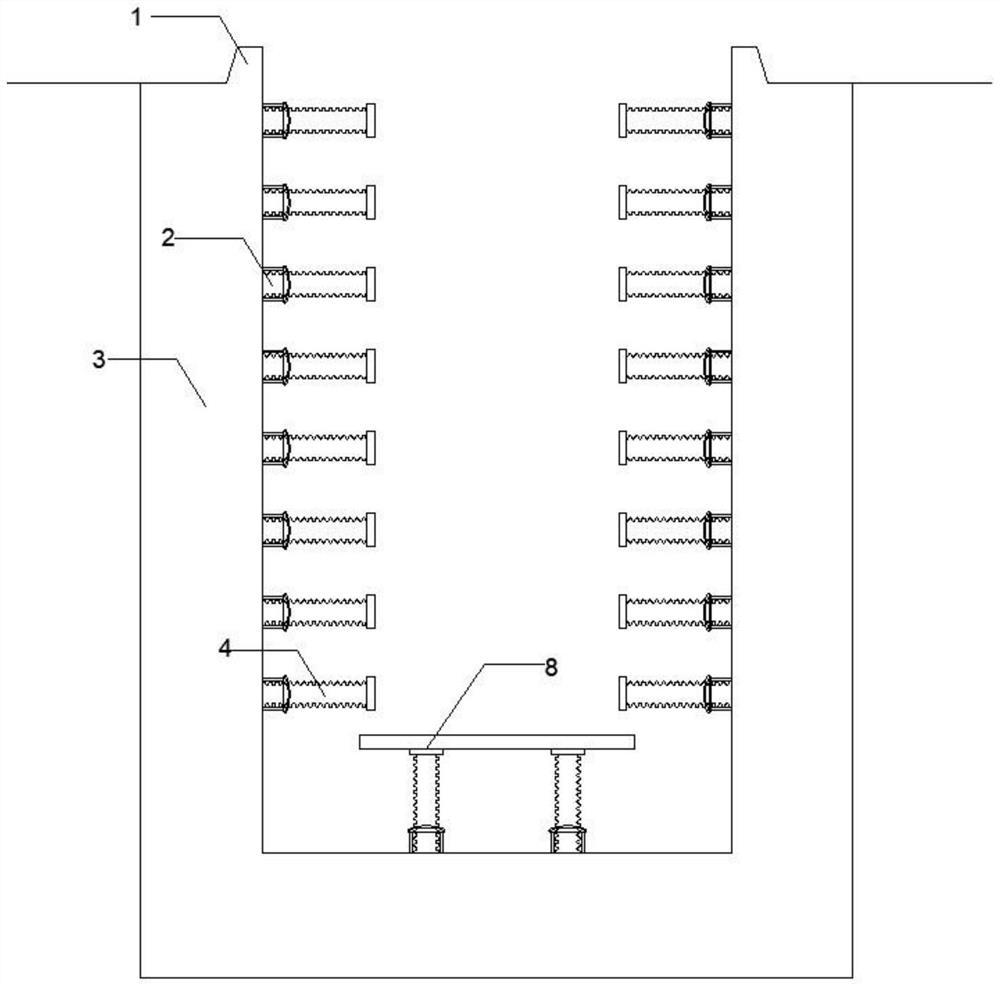

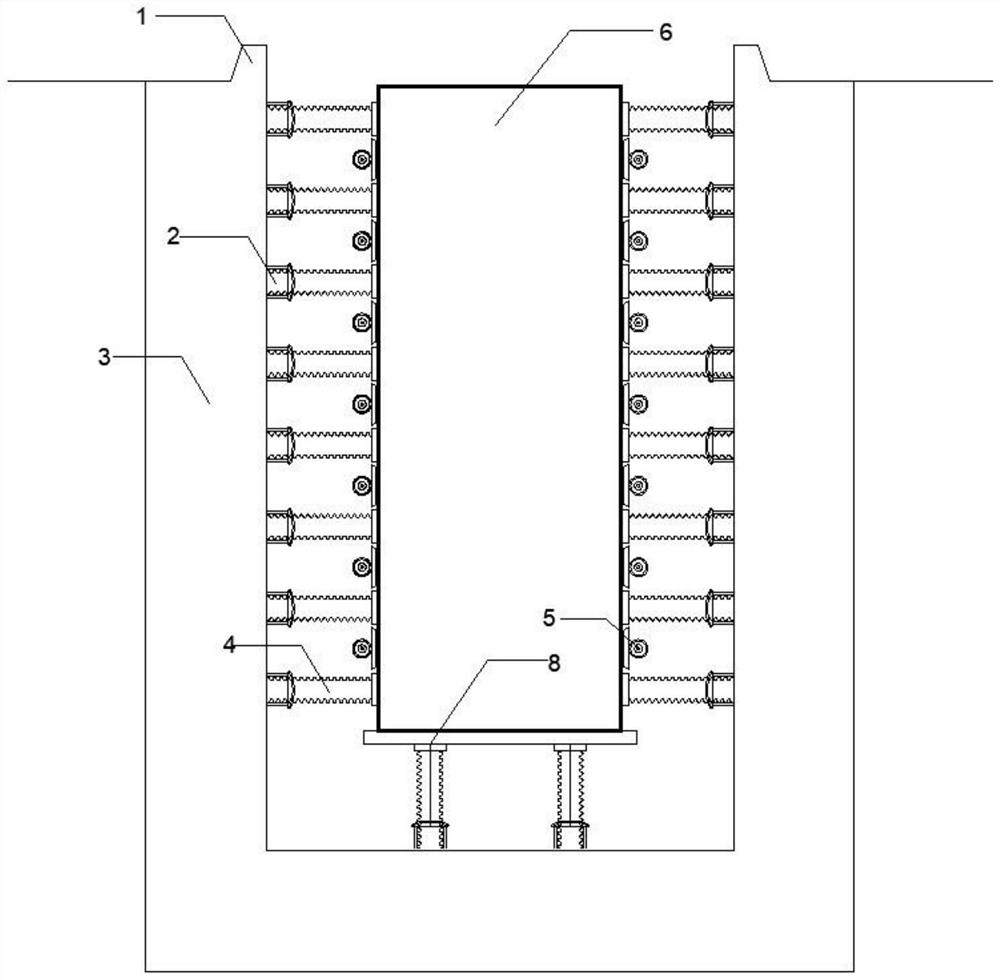

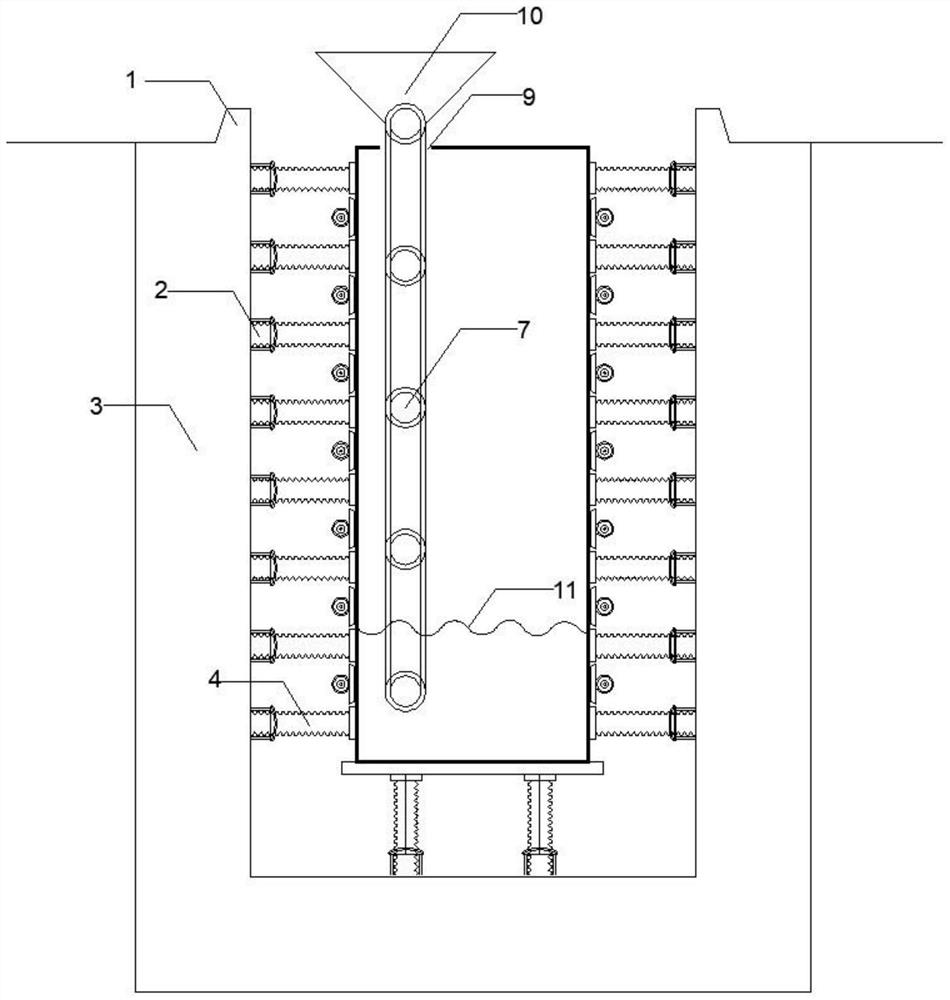

[0031] The present invention will be further described below in conjunction with specific embodiment, see Figure 1-Figure 3 , the invention provides a method for pouring concrete for a large ladle reinforced concrete protective door, which is a self-unloading vertical concrete pouring method for a large steel ladle reinforced concrete slab protective door, comprising the following construction steps:

[0032]1. Special fixed door slot 3: The special fixed door slot 3 is used as the fixed container for the ladle reinforced concrete protective door. The fixed door slot 3 is the core content of the present invention. The fixed door slot 3 is arranged below the ground and consists of a side wall, a bottom plate, a pre-embedded fixed fulcrum 2, an anti-collision safety pier 1, and an adjustable support base 8. The construction of the fixed door slot 3 should meet the following points: A. The bottom bearing capacity of the fixed door slot 3 should meet the requirements of bearing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com