Electric control actuator, tail gas treatment system and vehicle

An electric control actuator and exhaust gas treatment technology, which is applied in the direction of electric control, charging system, engine control, etc., can solve the problem that the electric control actuator is not finely laid out, the overall size of the electric control actuator is too large, and the internal installation Low space utilization and other issues, to achieve the effect of saving production costs, reducing assembly efficiency, and increasing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

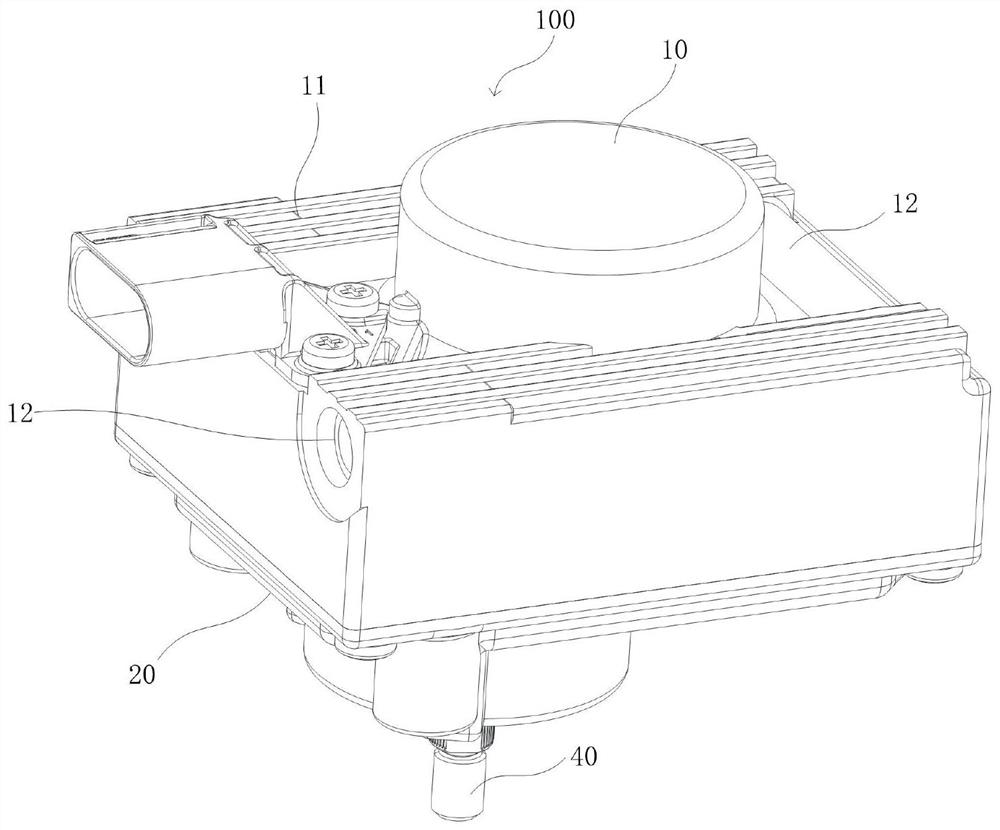

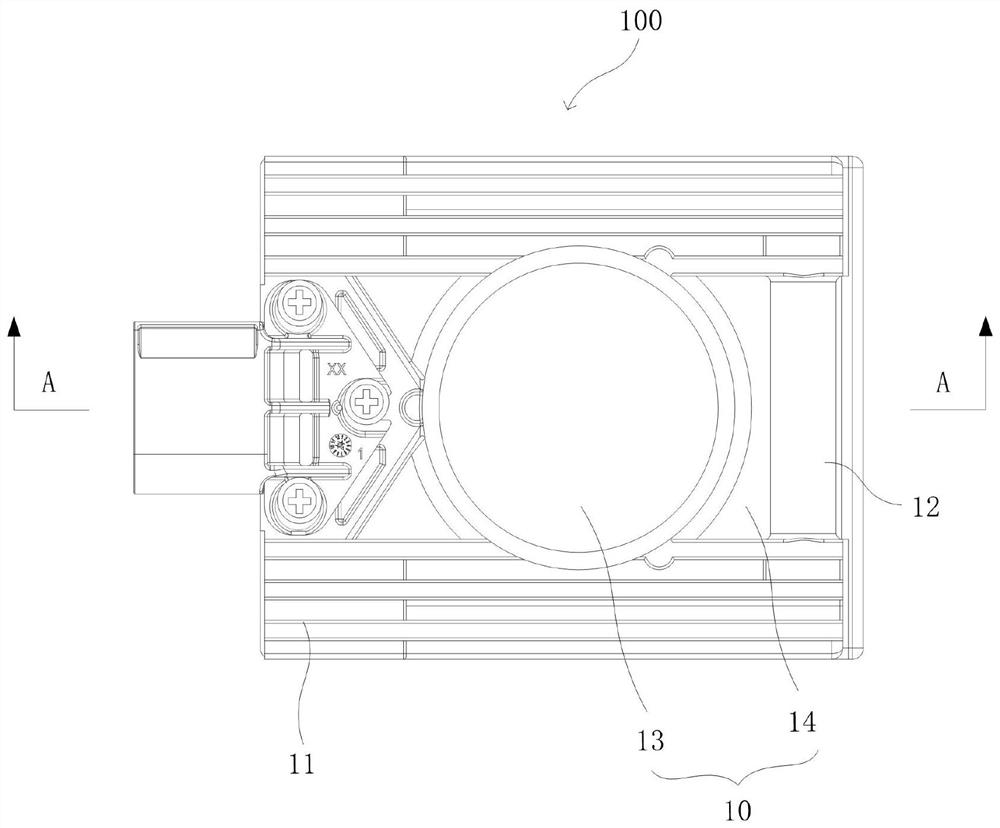

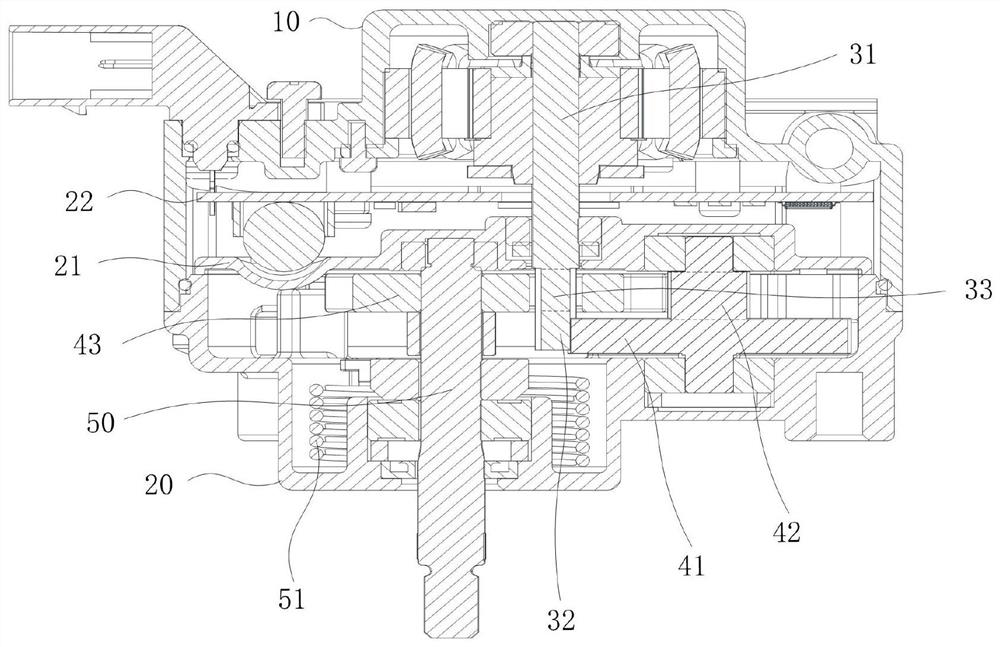

[0043] see figure 1 , which is a schematic structural diagram of an electronically controlled actuator 100 provided in Embodiment 1 of the present invention. The electric control actuator 100 includes, for example, a housing, a drive motor 30 and a compact gear assembly, wherein an installation space is provided in the housing, and the drive motor 30 and the compact gear assembly are all located in the installation space, and the compact gear assembly cooperates with the drive motor 30 Connection; the driving motor 30 is provided with a motor shaft 31, through which the transmission connection with the compact gear assembly can be realized.

[0044] combine Figure 2-Figure 5 Specifically, the compact gear assembly includes, for example, a first reduction gear 41 , a second reduction gear 42 and a sector gear 43 . The first reduction gear 41 is connected in transmission with the motor shaft 31; the second reduction gear 42 is coaxially fixedly connected with the first reduct...

Embodiment 2

[0063] Embodiment 2 of the present invention also provides an exhaust gas treatment system, for example, the exhaust gas treatment system includes the electronically controlled actuator 100 as described in Embodiment 1 above. Correspondingly, the technical effect corresponding to any one of the technical solutions in Embodiment 1 can be achieved, which will not be repeated here.

[0064] Preferably, the tail gas treatment system includes, for example, a valve, the valve is arranged on the exhaust gas circulation pipeline, and the electric control actuator 100 is used to control the opening or closing of the valve.

[0065] For example, the exhaust gas treatment system may be: a turbocharging system, an exhaust braking system, and an exhaust gas recirculation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com