Device and method for producing hydrogen and byproduct oxygen by using green electricity electrolyzed water

A technology for the electrolysis of water and oxygen, which is applied in the electrolysis process, electrolysis components, refrigeration and liquefaction, etc., can solve the problems that oxygen is not well utilized, the power generation process fluctuates greatly, and is uncontrollable, so as to achieve the economic benefits of enterprises and the environment. efficiency, reducing operating energy consumption, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

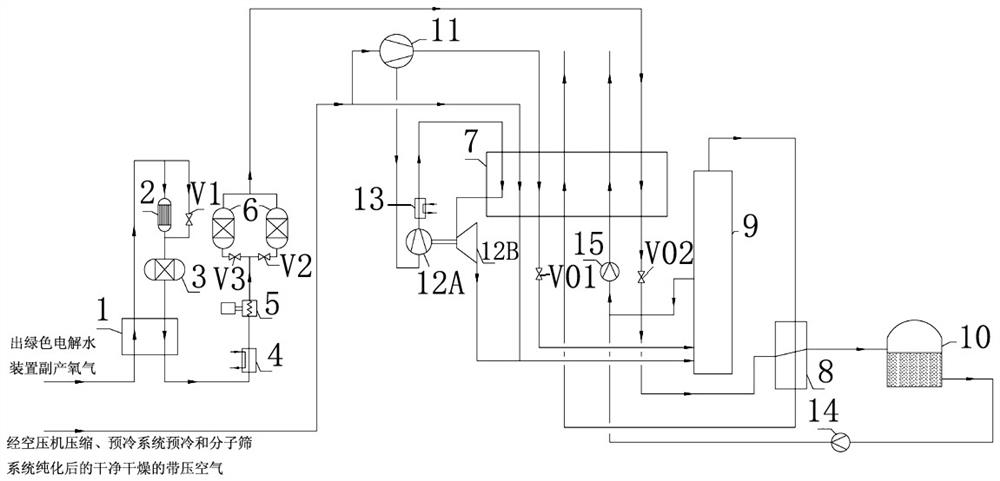

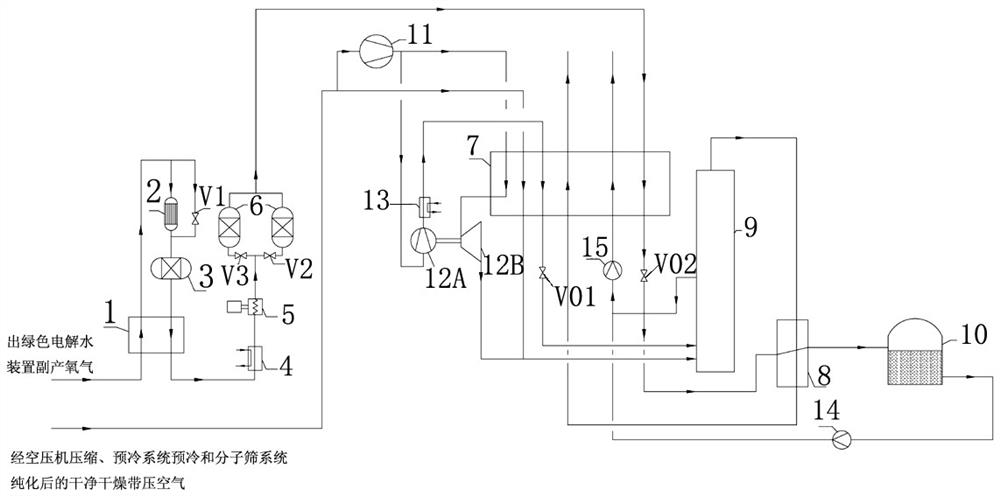

[0027] Such as figure 1 As shown: the pressure of the green electrolyzed water hydrogen production device is about 1.0 MPa. The by-product oxygen undergoes a chemical reaction in the oxygen purifier 3, converting the impurity H2 in the oxygen into H2O and CO into CO2; then in the oxygen purifier 6 Remove the impurities in the oxygen, and the CO in the oxygen after the oxygen purifier 6 2 and H 2 The O content is not more than 1ppm; the purified oxygen enters the heat exchanger 7, and exchanges heat with the return gas and process flow oxygen in the heat exchanger 7, so that the purified oxygen is cooled to a liquid state, and is throttled through the valve V02 to After 0.5MPa, liquid oxygen is obtained. When the green electricity is sufficient, this part of liquid oxygen is divided into two streams, one of which is combined with the liquid oxygen generated from the rectification of the air separation rectification system and enters the process. The liquid oxygen pump 15 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com