Plate heat exchanger for white smoke removal system

A plate heat exchanger, whitening technology, applied in direct contact heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problem of increasing the amount of pipelines and floor space, and long distances between flue gas and air , Poor whitening effect and other problems, to achieve the effect of preventing liquid re-evaporation, reducing residence time, and improving total heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

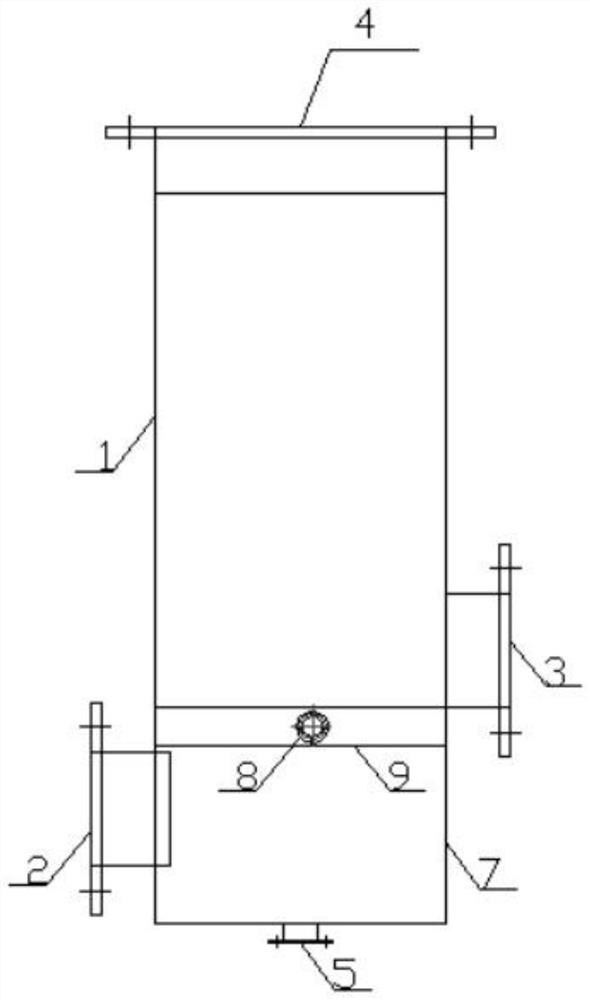

[0014] Attached below Figure 1-5 The technical scheme of the present invention will be further described.

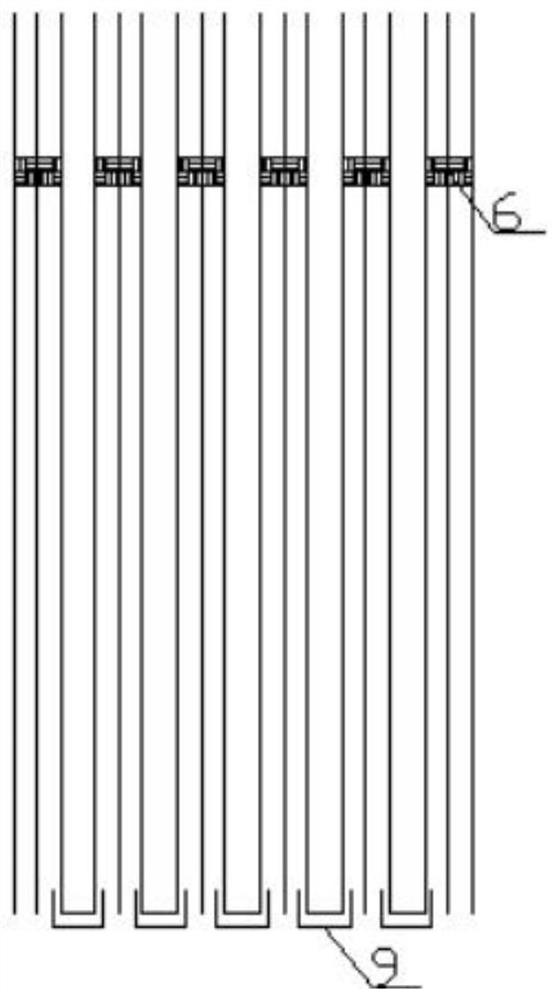

[0015] As shown in the figure, a plate heat exchanger for dewhitening system includes a hot cavity 1 located in the middle of the heat exchanger, a flue gas inlet pipe 2 located below the hot cavity 1, a flue gas duct 7 and The mixed gas outlet 4 is located above the hot cavity 1, and the inside of the hot cavity 1 is a heat exchange core, which is composed of molded corrugated rectangular heat exchange plates arranged in parallel; the middle and lower part of the thermal cavity 1 is provided with useful In addition to the defoaming screen 6 for blocking liquid droplets, the bottom of the flue gas duct 7 is provided with a liquid discharge port 5, and the lower part of the heat exchange core is provided with a liquid collection tank 9 for collecting condensate.

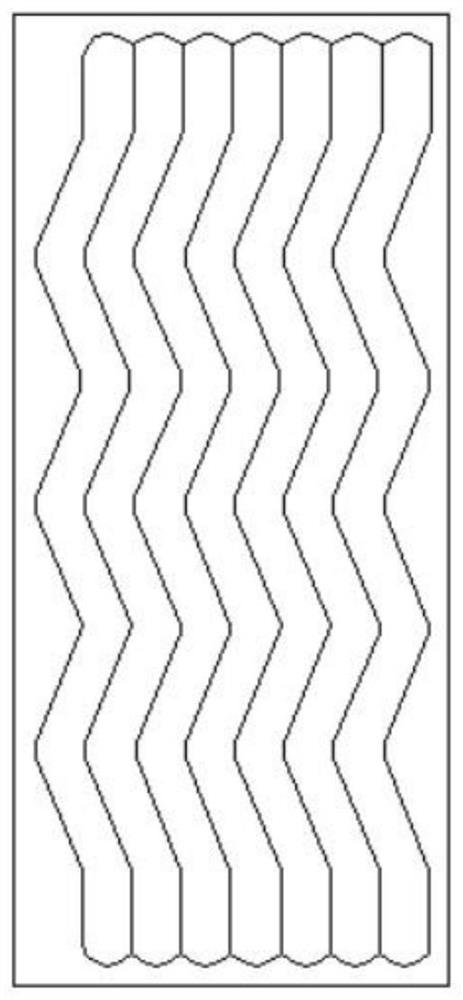

[0016] The heat exchange fin has a corrugated structure along the length, so that the flue gas channel is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com