Method for preparing N-polarity GaN based on CMP, N-polarity GaN and application of N-polarity GaN

A polarity and polarity surface technology, applied in the field of electronic science, can solve the problems of slow dry etching technology, increase of ohmic contact resistance, increase of surface roughness, etc., achieve low cost, reduce ohmic contact resistance, Effect of High Thinning Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

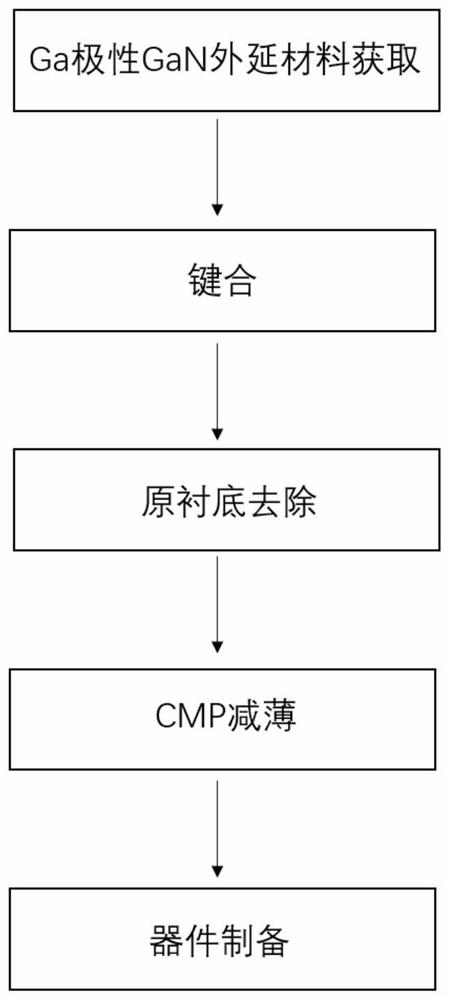

[0069] A method for preparing N-polar GaN based on CMP, comprising:

[0070] SiO with KOH as pH regulator and particle size of 10-60nm 2 As polishing abrasive particles, a polishing solution with pH=10 is configured;

[0071] Fix the wafer to be polished and thinned in the middle of the wafer carrier, and the wafer carrier is installed on the carrier assembly, so that the surface of the wafer to be polished and thinned is in contact with the polishing pad, and the wafer to be polished and thinned is provided with 8N by the carrier assembly. The pressure, the speed of the polishing pad is 30 rpm, the flow rate of the polishing solution is 10ml / min, the speed of the wafer carrier is 50 rpm, and the polishing time is 10 minutes; use N-polar AlN (AlGaN) and N-polar GaN polishing Selective polishing with high selectivity ratio of thinning rate, fast removal of 200nm AlN nucleation layer and 2μm AlGaN stress buffer layer, slow removal of GaN layer, until the surface of N-polar GaN ...

Embodiment 2

[0074] A method for preparing N-polar GaN based on CMP, comprising:

[0075] SiO with a particle size of 20-30nm using NaOH as a pH regulator 2 As polishing abrasive particles, a polishing solution with pH=12 is configured;

[0076] Fix the wafer to be polished and thinned in the middle of the wafer carrier, and the wafer carrier is installed on the carrier assembly so that the surface of the wafer to be polished and thinned is in contact with the polishing pad; and the wafer to be polished and thinned is provided with a pressure of 15N by the carrier assembly , the rotating speed of the polishing pad is 20 rpm, the flow rate of the polishing liquid is 10ml / min, the rotating speed of the wafer carrier is 30 rpm, and the polishing time is 6 minutes; using N-polarity AlN (AlGaN) and N-polarity GaN polishing thinning Selective polishing with a high selectivity ratio, quickly removes the 200nm AlN nucleation layer and 2μm AlGaN stress buffer layer, and slowly removes the GaN laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com