Copper bar electrotinning bath

A technology for electroplating tin and copper bars, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of temperature rise, environmental impact, and electroplating efficiency decline, and achieve the effect of reducing pollution, reducing damage, and improving electroplating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

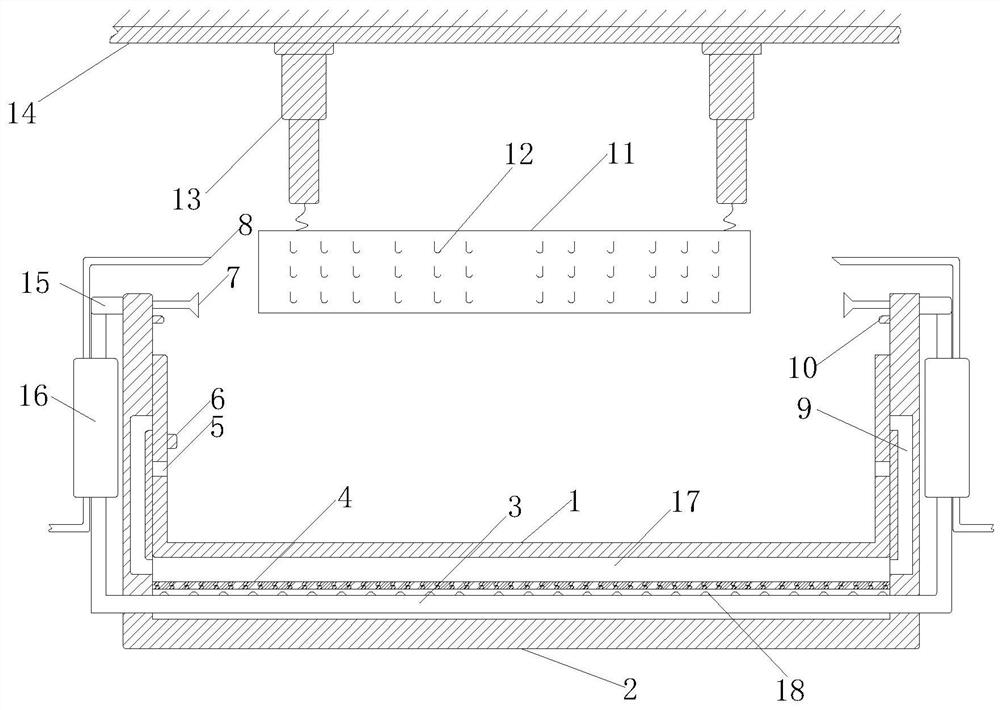

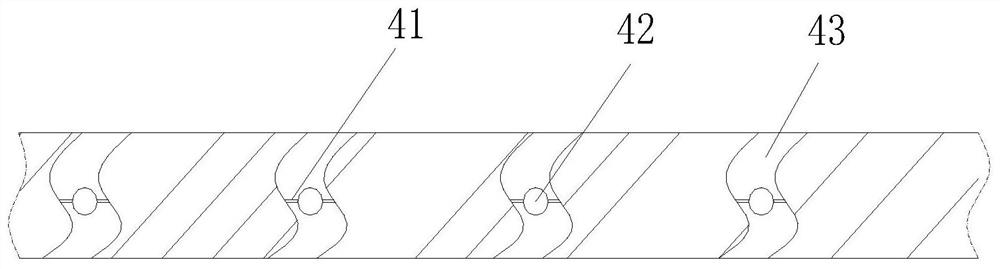

[0034] As a specific embodiment of the present invention, the trachea 3 runs through the chamber 17 , and the upper side wall of the part of the trachea 3 located in the chamber 17 is provided with air holes 18 .

[0035] When the gas reaches the chamber 17 through the heat exchanger 16, a protruding air hole 18 is provided on the upper side pipe wall of a section of the air pipe 3 in the chamber 17, and the gas flows out from the air hole 18 to achieve the effect that the gas flows out evenly, which helps While the gas is fully filtered, the stability of the gas pushing the inner tank 1 to move is improved.

[0036]The present invention not only enables the electroplating solution to be uniformly distributed in the electroplating process by utilizing the harmful gas and air generated, but also enables the harmful gas to be filtered during the electroplating process, thereby improving the electroplating effect of copper bars and reducing the emission of harmful gases .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com