Heat recovery system and method for low-load operation stage of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor, operation stage technology, applied in the field of nuclear power, can solve the problems of energy waste, energy is not effectively used, etc., and achieve the effects of low renovation cost, realization of recycling, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

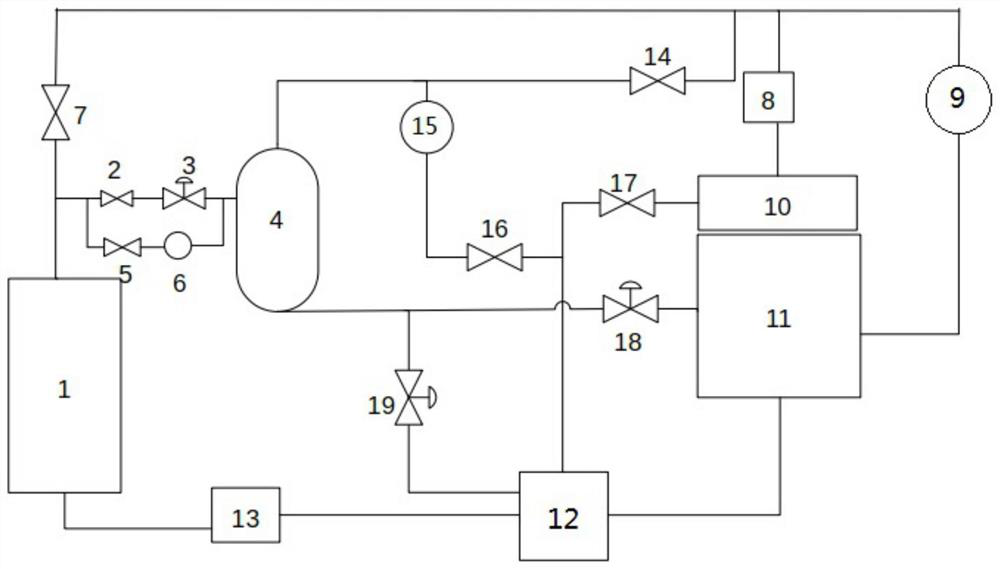

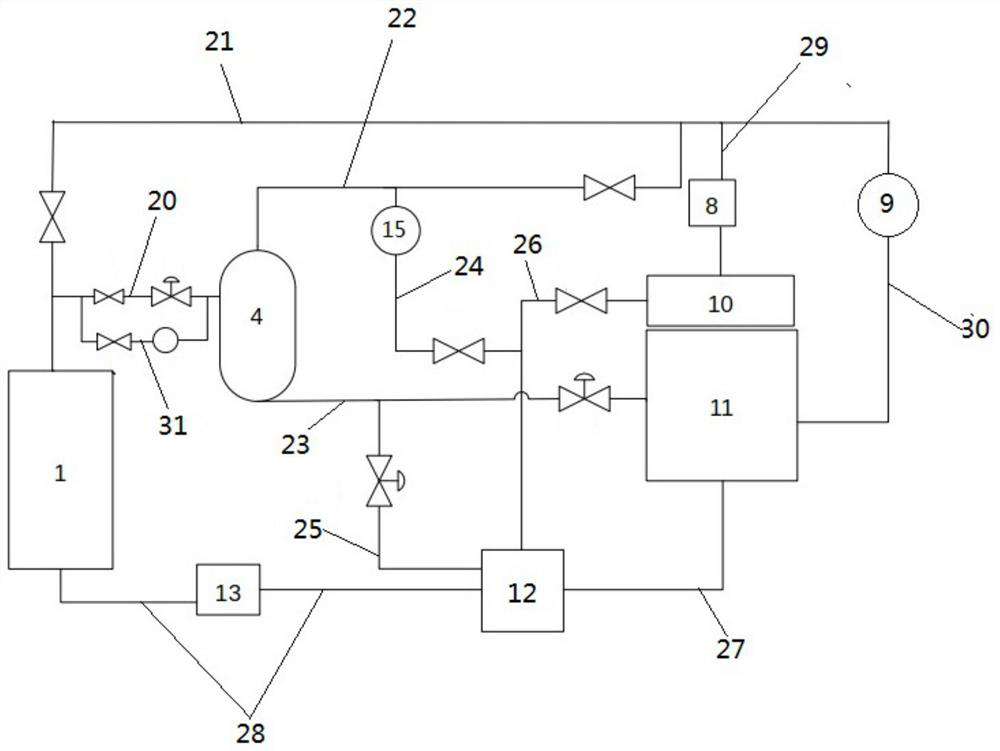

[0051] This embodiment provides a heat recovery method in the low-load operation stage of a high-temperature gas-cooled reactor, which is specifically divided into the following six stages:

[0052] At the initial stage of reactor start-up, the first cut-off valve 2 is opened, the outlet feed water of the steam generator flows into the steam-water separator 4 through the first pipeline, and the first regulating valve 3 controls the pressure at the outlet of the steam generator to be 13.9Mpa.

[0053] In the first period of time, when the outlet feed water in the steam generator is saturated water stage, the second regulating valve 18 is opened to discharge the water in the steam-water separator to the condenser, and at the same time, the second regulating valve 18 is used to control the water in the steam-water separator. liquid level. When the internal pressure of the steam-water separator is higher than the operating pressure of the deaerator, the fifth stop valve 16 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com