Liquid fuel nozzle for dual-radial swirler dual-fuel combustion chamber

A liquid fuel and swirler technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of poor premixed combustion stability, high diffusion combustion emissions, and ensure efficient and stable combustion, efficient and stable combustion, The effect of preventing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

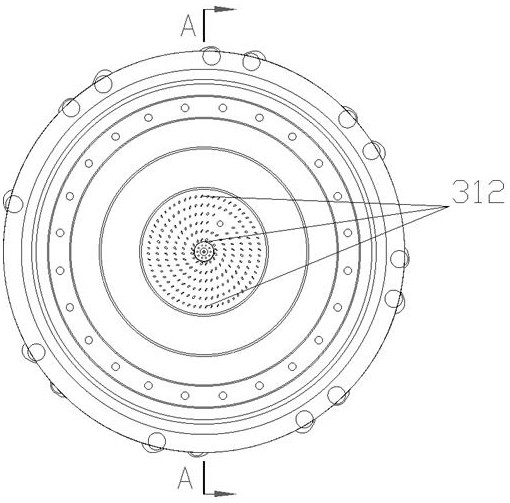

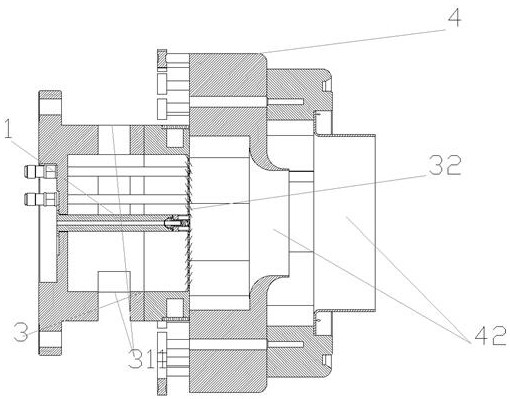

[0058] like Figure 1-4 As shown, a liquid fuel nozzle for a double diameter turntorm dual fuel combustion chamber comprises a crime-level nozzle 1, a primary fuser 2, a front mounting section 3, a vortex 4, and the above zero component is assembled into a whole, Complete atomization evaporation of the burner head fuel.

[0059] Specifically, the front mounting section 3 includes a front mounting segment front section 31 and a rear segment, the front end of the turntorm 4 fixed to the rear segment of the front mounting section 3, and the value-class nozzle 1 is mounted on the center axis of the front mounting section 3, on duty Level nozzle 1 is connected to the vortex throat 42; the front end surface of the eddy current collector 4 is arranged centrally to the center circumference, and the main stage spray rod 2 is arranged, and the main stage sprinkler 2 is connected to the vortex blade passage 41. The front mounting section 3 and the contact surface of the turntorm 4 are the fro...

Embodiment 2

[0063] like Figure 5-7 As shown, on the basis of Example 1, the value class nozzle 1 includes a swirl core 11, a spray tube 12, a crime-level nozzle cooling cover 13, a crime-level nozzle rod 14, a crime-level nozzle rod 14 is mounted in a swirling flow The top of the core 11, the tail end set of the swirl core 11, the outer sleeve of the spray tube 12, the outer sleeve 13; the top of the value class nozzle rod 14 is a crime-level fuel inlet 111, a crime-level nozzle rod 14 The center is axially in a crime-level fuel flow path, and the tail of the spray tube 12 is funnel shape, and the bottom of the funnel is nozzle 114.

[0064] The cyclone core 11 includes a top, intermediate cylindrical segment, and a bottom end, and the top is tapered or spherical, the top and the criterioned nozzle rod 14 forms a tapered or spherical sealing structure, the intermediate of the top and the cylindrical segment. The hollow structure, the bottom of the cylindrical section is the end surface of the...

Embodiment 3

[0070] like Figure 8-9 As shown, on the basis of Example 1 or 2, the axial intermediate of the main fuel spray rod is the main fuel-grade fuel flow path, one end of the main burn-fuel-fuel flow path is the main stage sprinkler fuel inlet 211, another One end is the main fuel outlet; the sidewall of the main fuel spray rod is provided with several major fuel spray rods 212 for the main burn-fuel flow inflow, and the main fuel spray rod spout 212 is associated with the main stage 2 The main level fuel flow in the middle is connected.

[0071] The main bonded fuel is inflows from the primary fuel inlet 211 on the main fuel spray rod, and the main fuel spray rod spout 212 takes a simple hole pressure atomization method to obtain an initial homoa oil cone that satisfies the requirements, and sprayed with eddy current. The blade passage 41.

[0072] The main burn-fuel fuel and the eddy current collector 4 cooperate Figure 10-12 As shown, by using the structure of the open inclined hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com