Coal ash sintering temperature prediction method based on principal component regression

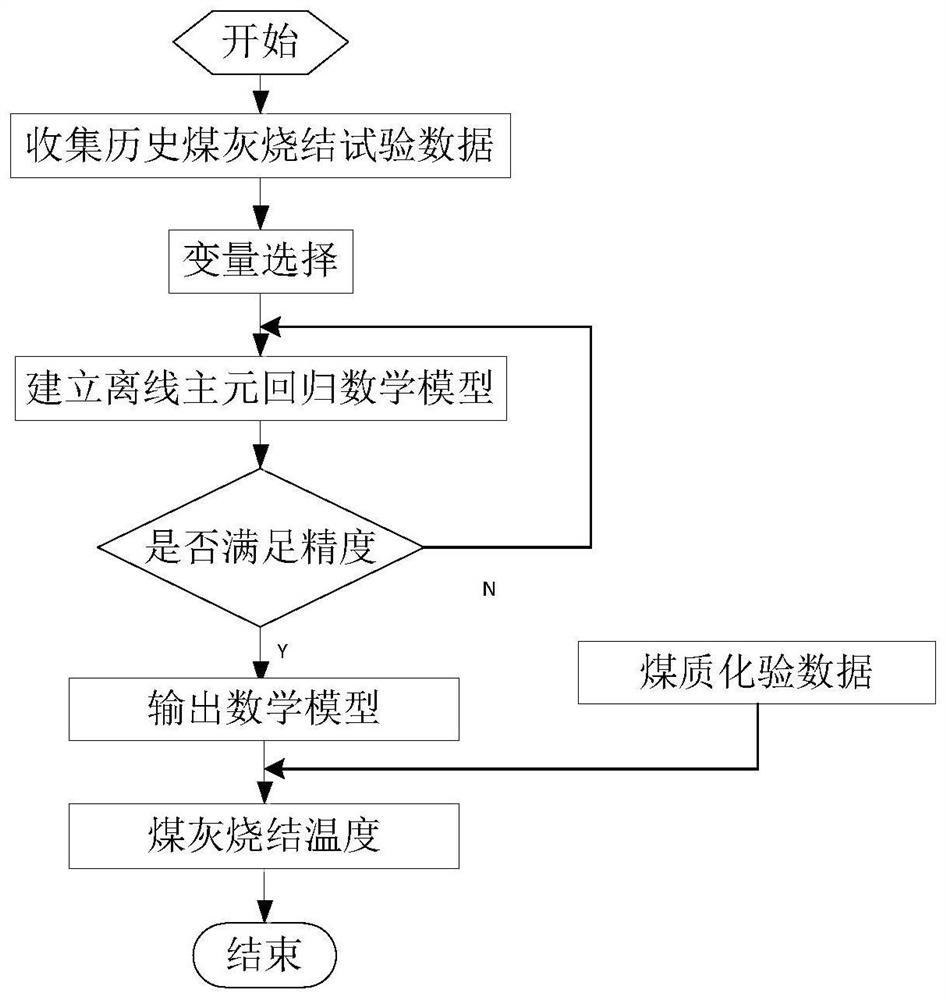

A technology of sintering temperature and principal element regression, which is applied in complex mathematical operations, design optimization/simulation, calculations, etc., can solve problems such as poor prediction accuracy and small amount of historical test data, and achieve good accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

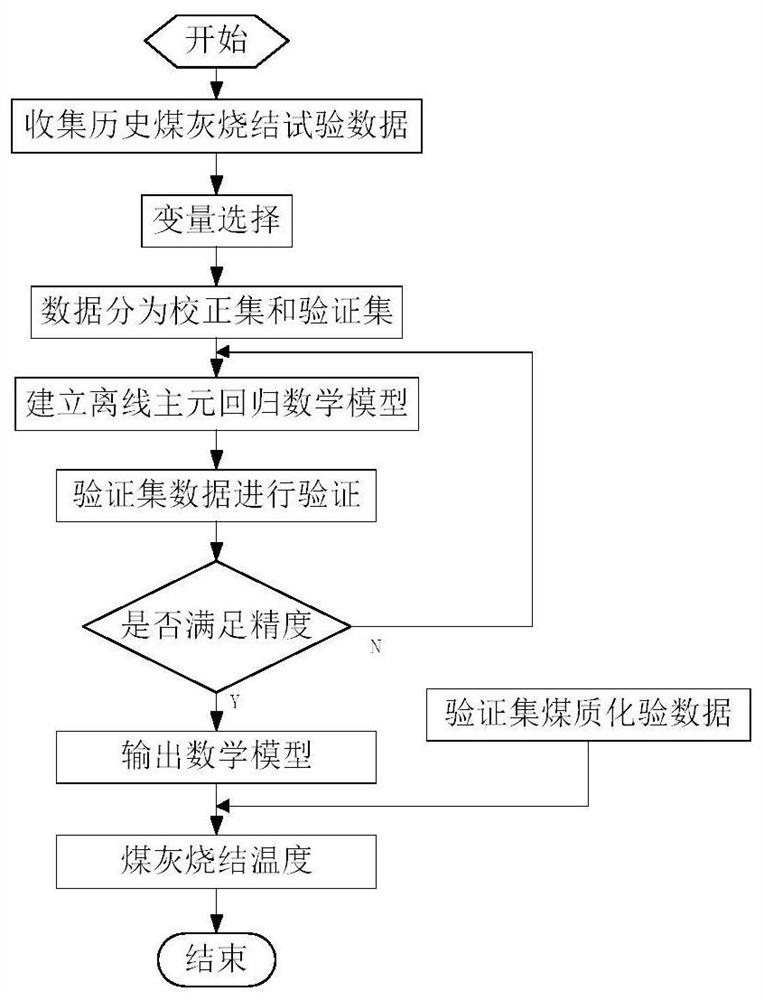

[0091] This example involves the prediction of the sintering temperature of coal ash of typical domestic slagging and contaminated coals. The main coals are Shenhua coal, Binchang coal, Lu'an coal, Shanxi coal, Jingbian coal, Wucaiwan coal and kaolin. For the prediction of sintering temperature under the ratio, the specific prediction model is established as figure 2 shown.

[0092] Step 1: Collect test samples, collect test coal quality data and laboratory coal ash initial sintering temperature test data, test coal types are shown in Table 2, a total of 26 coal samples.

[0093] Table 2 Test coal samples

[0094]

[0095]

[0096]

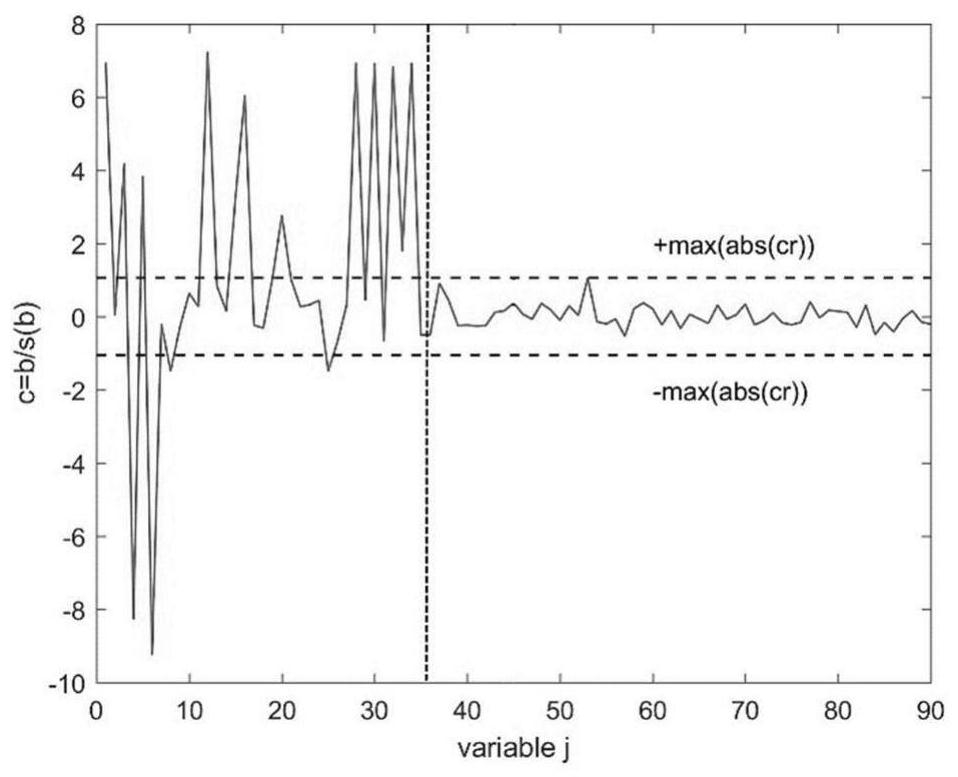

[0097] Step 2: Useless information variable removal

[0098] Generate a random matrix S as the noise matrix. The S matrix takes the standard normal distribution and has the same dimensions as the original calibration sample set X, and is added to the matrix X to form a new matrix XS. The elements in the added noise matrix S should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com