Energy-saving and environment-friendly waste glass recycling device

A technology for waste glass, energy saving and environmental protection, applied in the direction of grain processing, etc., can solve the problem of inability to classify and collect glass according to specifications, and achieve the effect of accelerating the rolling speed and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

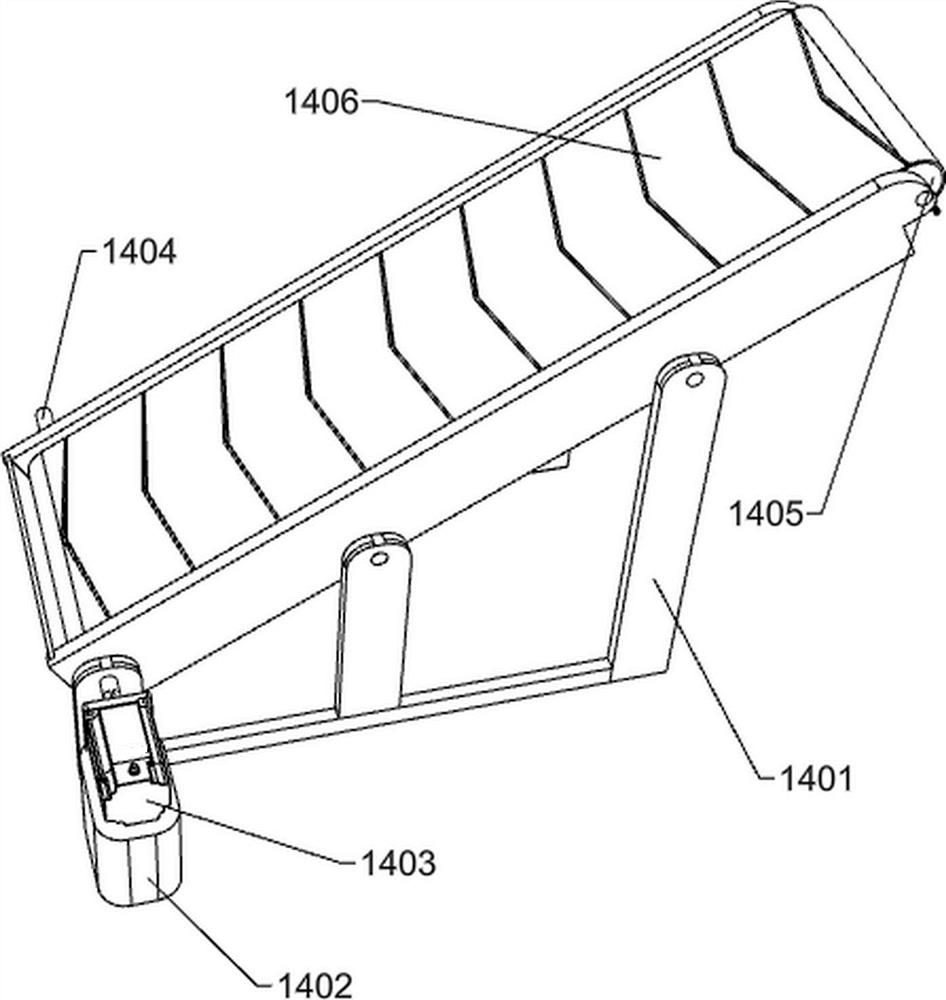

[0074] A waste glass recycling device for energy saving and environmental protection, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a crushing frame 2, a first rotating shaft 3, a first rotating sleeve 4, a first shaft seat 5, a second rotating shaft 6, a pulley set 7, a first mounting seat 8, a first motor 9, Small breaking hammer 10, large breaking hammer 11, first bevel gear 12, second bevel gear 13 and transmission mechanism 14, the top of the bottom plate 1 is provided with a crushing frame 2, and the inner wall of the crushing frame 2 is connected with a first rotating shaft 3. The first rotating shaft 3 is provided with a first rotating sleeve 4, and the top right side of the bottom plate 1 is provided with two first shaft seats 5, and the first shaft seats 5 are provided with a second rotating shaft 6 , the two sides of the second rotating shaft 6 and the first rotating sleeve 4 are connected with a pulley set 7, the top right side...

Embodiment 2

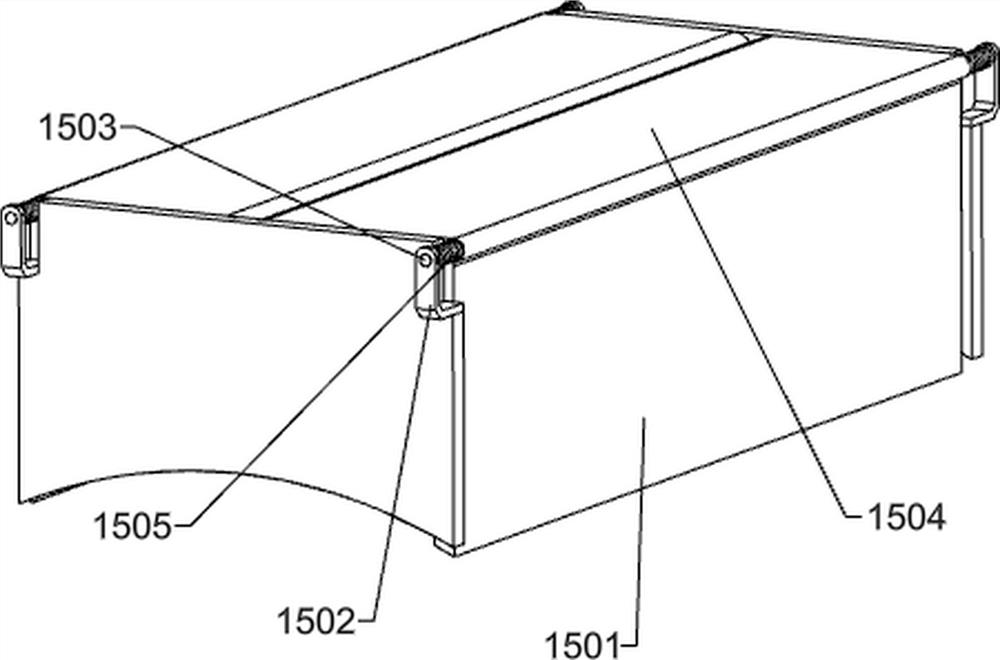

[0078] On the basis of Example 1, such as Figure 4 As shown, an anti-splash mechanism 15 is also included. The anti-splash mechanism 15 includes a first support frame 1501, a fourth rotating shaft fixing frame 1502, a fifth rotating shaft 1503, a rotating plate 1504 and a torsion spring 1505. The top of the crushing frame 2 is set There is a first supporting frame 1501, and fourth rotating shaft fixing frames 1502 are symmetrically arranged on both sides of the upper part of the first supporting frame 1501, and fifth rotating shafts 1503 are rotatably arranged between the longitudinal fourth rotating shaft fixing frames 1502, so A rotating plate 1504 is disposed on the fifth rotating shaft 1503 , and a torsion spring 1505 is connected between the rotating plate 1504 and the fixing frame 1502 of the fourth rotating shaft.

[0079] When crushing waste glass products, the staff can turn the rotating plates 1504 on both sides upward, and the torsion spring 1505 is deformed. When ...

Embodiment 3

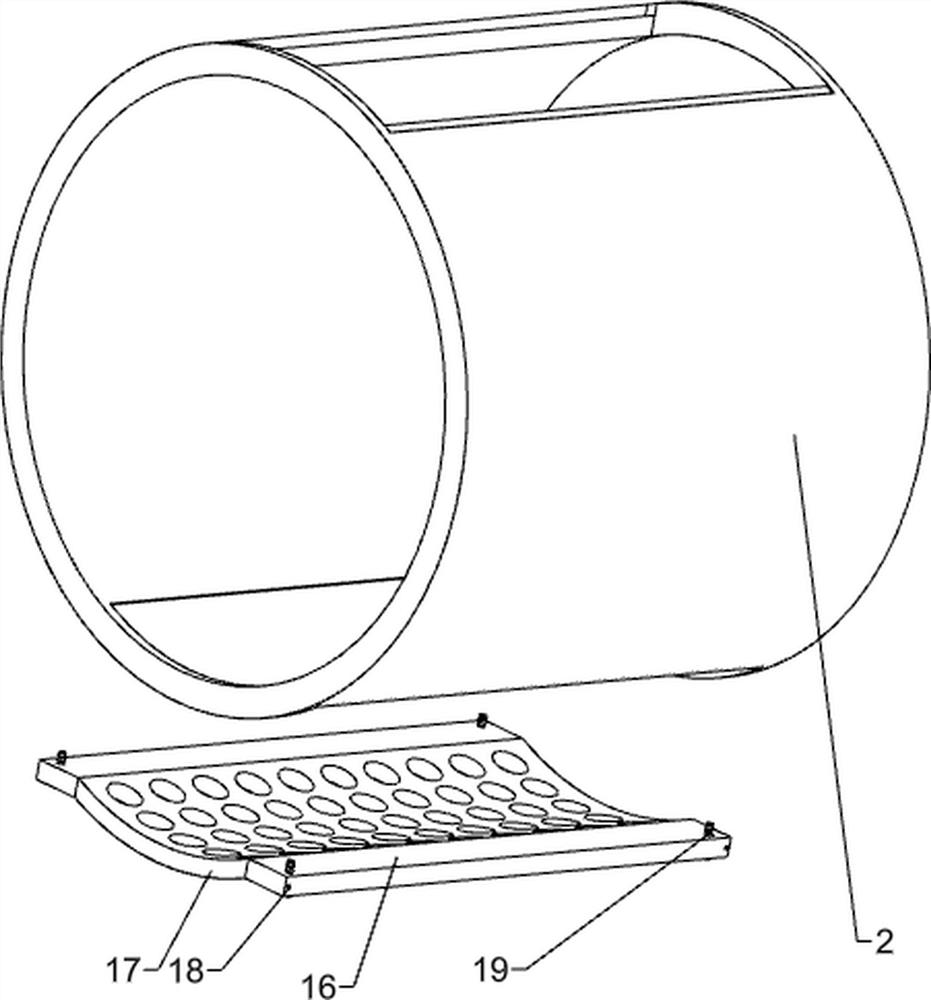

[0081] On the basis of Example 2, such as Figure 5-Figure 8 As shown, it also includes a positioning plate 16, a large screen 17, a first fixing screw 18 and a second fixing screw 19, and the positioning plate 16 is detachably installed in the broken At the bottom of the frame 2, a large screen 17 is arranged between the positioning plates 16.

[0082] When it is necessary to classify and collect the broken glass slag, the glass slag falls on the large screen 17 to screen the glass slag, and the staff can turn the first fixing screw 18 and the first fixing screw 18 to facilitate the removal of the glass slag. The large screen 17 is taken out and replaced, which is convenient for the staff to work better.

[0083] It also includes a second support frame 20, a positioning frame 21, a middle screen 22, a small screen 23, a supporting plate 24 and a sixth rotating shaft 25, and both sides of the bottom plate 1 are provided with a second support frame 20, the The sixth rotating ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap