Ultrasonic generator based on direct-current power supply

A technology of DC power supply and ultrasonic wave, applied in current collectors, electric vehicles, electrical components, etc., can solve problems such as large layout space of self-generating structures, improve hole forming speed and drilling efficiency, delay air flow speed, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

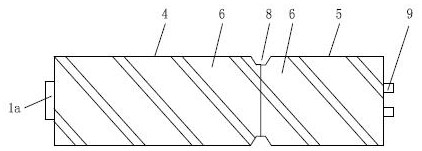

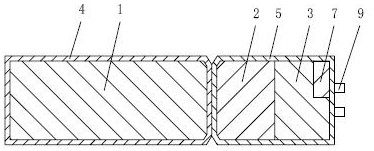

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

[0017] see figure 1 , figure 2 , an ultrasonic generator based on a DC power supply, comprising a DC power supply 1, an inverter circuit 2, an ultrasonic generation circuit 3 and a remote control unit 7, the DC power supply is made of a rechargeable battery with a charging interface 1a; the remote control unit 7 It has a frequency adjustment circuit and an opening and closing control circuit, and is used to manage and control the DC power supply 1 , the inverter circuit 2 and the ultrasonic generating circuit 3 .

[0018] Wherein, it also includes a first housing 4 and a second housing 5, the first housing and the second housing are coaxially fixedly connected; the DC power supply 1 and the ultrasonic generating circuit 3 are enclosed in the first housing 4; The charging interface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com