Directional drilling machine drill bit capable of assisting rapid drilling through ultrasonic vibration

A directional drilling rig and ultrasonic technology, applied in directional drilling, drill bits, vibration generating devices, etc., can solve the problems of inapplicability, large installation space of self-generating structures, etc., achieve fast hole forming speed, improve disassembly and assembly convenience, and drill The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

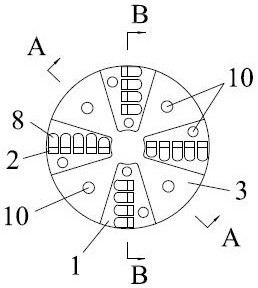

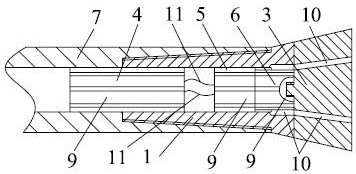

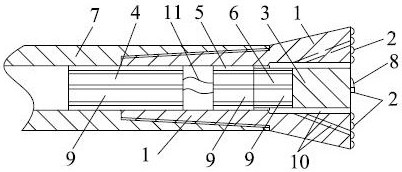

[0020] see figure 1 , figure 2 , image 3 , a directional drill bit for ultrasonic vibration-assisted rapid drilling, comprising a drill body 1 that can be screwed and fixed on the front end of a drill rod 7, the drill body 1 is in a hollow structure, the front end of the drill body 1 is in a multi-claw structure, and each claw The drill teeth 2 are installed through the mounting base 8; the front end of the drill bit main body 1 is provided with an ultrasonic actuator 3, and the ultrasonic actuator 3 has a radial extension embedded in the adjacent tooth groove; the ultrasonic actuator 3 is used After the ultrasonic signal generated by the ultrasonic generator 4 is converted and amplified by the energy converter 5 and the amplitude converter 6, it acts on the rock mass; the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com