Transportation crown block system of crystallizer copper pipe machining assembly line

A crystallizer copper tube and assembly line technology, which is applied in the field of transportation, can solve the problems such as the inability of the transportation crane to move complicatedly, and achieve the effect of fast transportation speed and automatic system processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

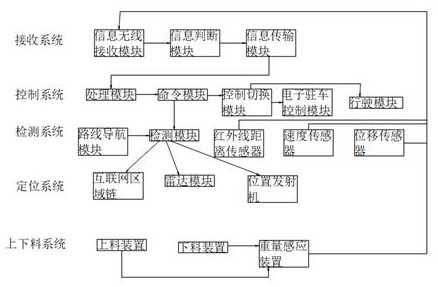

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a transport crane system for the mold copper tube processing line, including a receiving system, a control system, a detection system, a positioning system and a loading and unloading system.

[0030] The receiving system includes an information wireless receiving module for receiving external information;

[0031] An information judgment module for judging received information;

[0032] The information is transmitted to the next system information transmission module.

[0033] The control system includes a command module for controlling the transport crane;

[0034] A processing module for processing relevant information;

[0035] A control switching module for switching related motion controls;

[0036] Electronic parking control module for parking the crane;

[0037] The driving module that moves the transport crane.

[0038] The detection system includes a route navigation module for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com