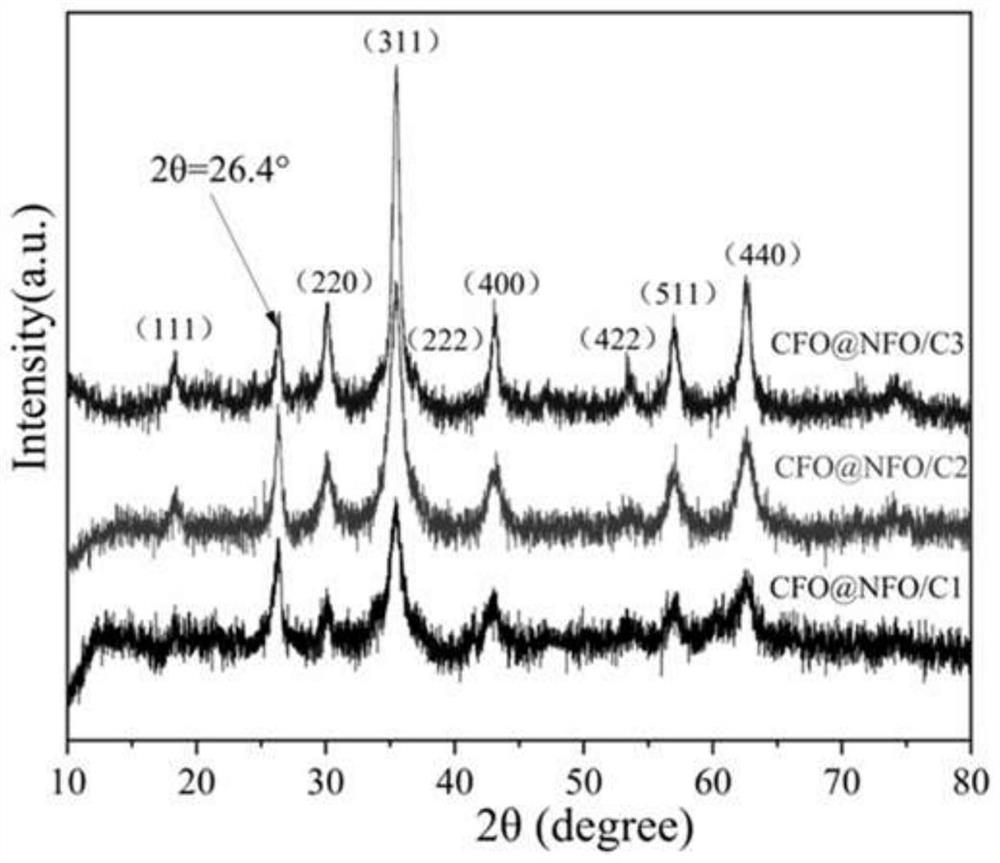

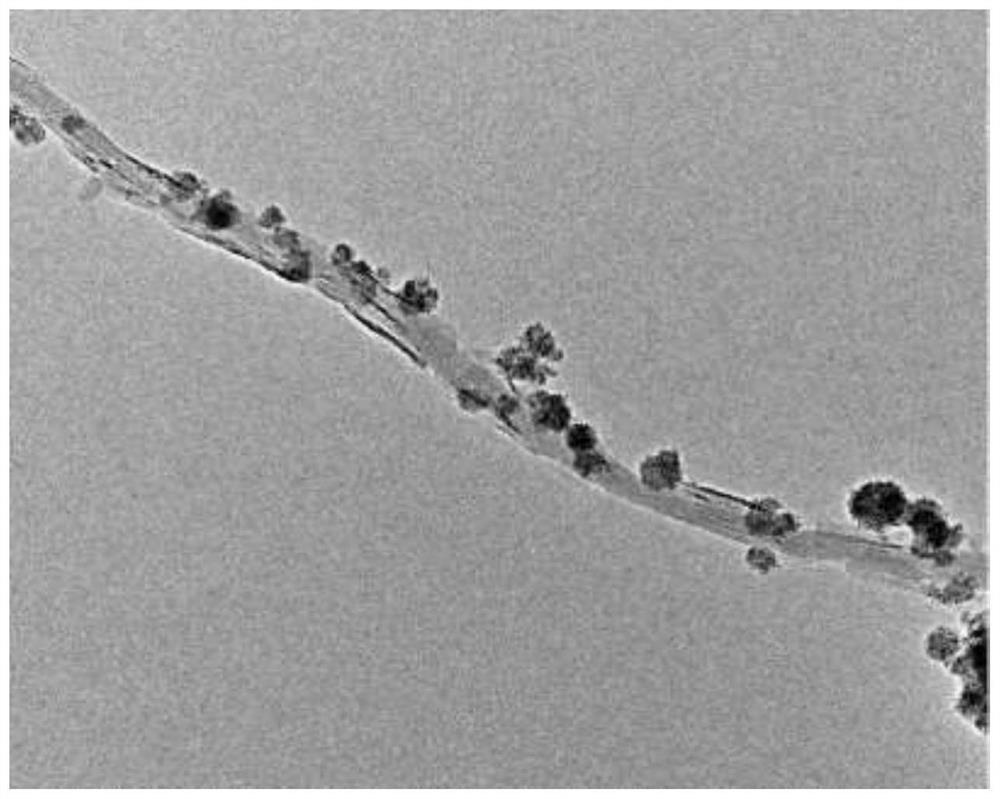

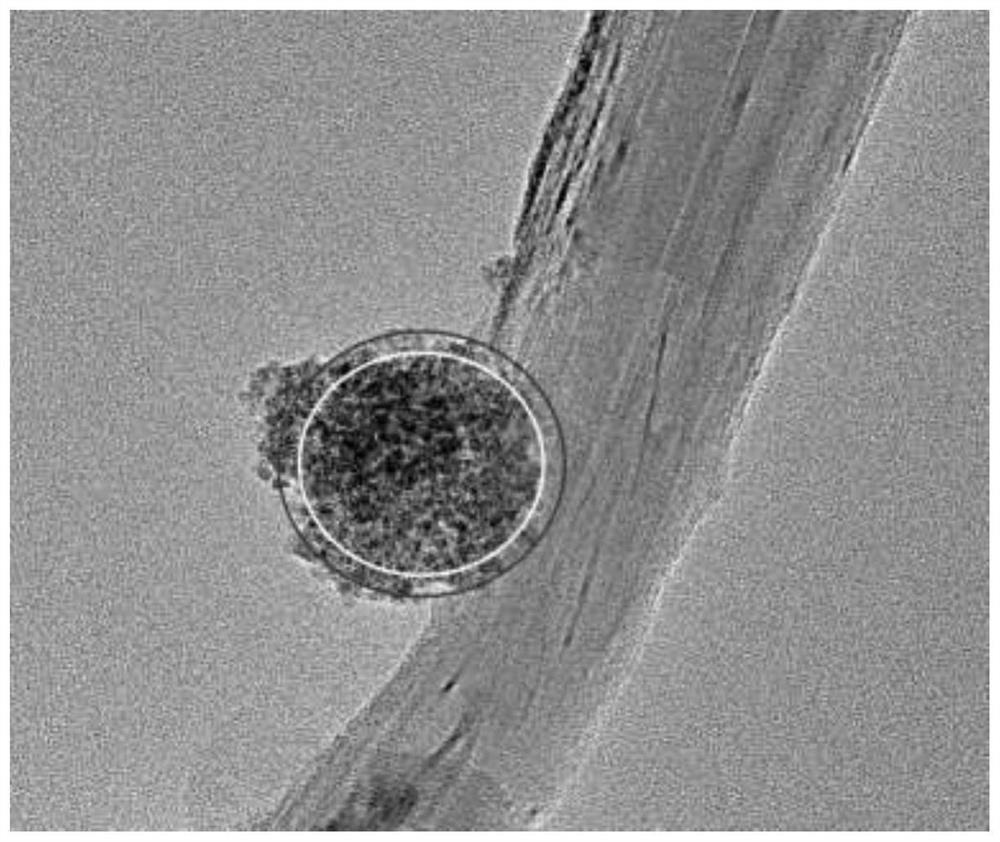

Ternary composite wave-absorbing material with core-shell structure and preparation method thereof

A ternary composite and wave-absorbing material technology, applied in shielding materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., to achieve excellent microwave absorption performance, high effective wave-absorbing frequency bandwidth, and good impedance matching The effect of the attenuation characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A spherical ternary composite absorbing material with a core-shell structure, according to CoFe 2 o 4 with NiFe 2 o 4 The mass ratio of 3:1 requires the design of the composite absorbing material, and the specific preparation method comprises the following steps:

[0041] 1) Preparation of acidified carbon nanofibers

[0042] First measure 60mL mixed acid (concentration is 98% concentrated sulfuric acid concentration is 95% and concentrated nitric acid is mixed with the volume ratio of 3:1) is placed in beaker, then adds 1.0g carbon nanofiber, moves in the 100ml there-necked flask, transfers Stir magnetically in an oil bath at 80°C, carry out condensation and reflux treatment, and the acidification process lasts for 6 hours; ℃ in a vacuum oven for 12 hours to obtain acidified carbon nanofibers, which are denoted as O-CNFs;

[0043] 2) Preparation of CoFe by solvothermal method 2 o 4

[0044] Take 50ml of ethylene glycol (EG) and place it in a 100ml beaker, add 0...

Embodiment 2

[0053] A spherical ternary composite absorbing material with a core-shell structure, according to CoFe 2 o 4 with NiFe 2 o 4 The mass ratio of 1:1 requires the design of the composite absorbing material, and the specific preparation method comprises the following steps:

[0054] 1) Preparation of acidified carbon nanofibers

[0055] First measure 60mL mixed acid (concentration is 98% concentrated sulfuric acid concentration is 95% and concentrated nitric acid is mixed with the volume ratio of 3:1) is placed in beaker, then adds 1.0g carbon nanofiber, moves in the 100ml there-necked flask, transfers Stir magnetically in an oil bath at 80°C for condensation and reflux treatment. The acidification process lasts for 6 hours; Dry in a vacuum oven at 60°C for 12 hours to obtain acidified carbon nanofibers, which are denoted as O-CNFs;

[0056] 2) Preparation of CoFe by solvothermal method 2 o 4

[0057] Take 50ml of ethylene glycol (EG) into a 100ml beaker, add 0.595g of CoC...

Embodiment 3

[0063] A spherical ternary composite absorbing material with a core-shell structure, according to CoFe 2 o 4 with NiFe 2 o 4 The mass ratio of 1:3 requires the design of the composite absorbing material, and the specific preparation method comprises the following steps:

[0064] 1) Preparation of acidified carbon nanofibers

[0065] First measure 60mL mixed acid (concentration is 98% concentrated sulfuric acid concentration is 95% and concentrated nitric acid is mixed with the volume ratio of 3:1) is placed in beaker, then adds 1.0g carbon nanofiber, moves in the 100ml there-necked flask, transfers Stir magnetically in an oil bath at 80°C for condensation and reflux treatment. The acidification process lasts for 6 hours; Dry in a vacuum oven at 60°C for 12 hours to obtain acidified carbon nanofibers, which are denoted as O-CNFs.

[0066] 2) Preparation of CoFe by solvothermal method 2 o 4

[0067] First, measure 50ml of ethylene glycol (EG) into a 100ml beaker, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com