Step-by-step temperature compensation method for fiber-optic gyroscope

A technology of fiber optic gyroscope and temperature compensation, applied in neural learning methods, Sagnac effect gyroscopes, instruments, etc., can solve problems such as temperature drift, circuit equivalent phase error drift, poor generalization ability, etc., and achieve higher temperature Environmental adaptability, improved zero bias stability, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

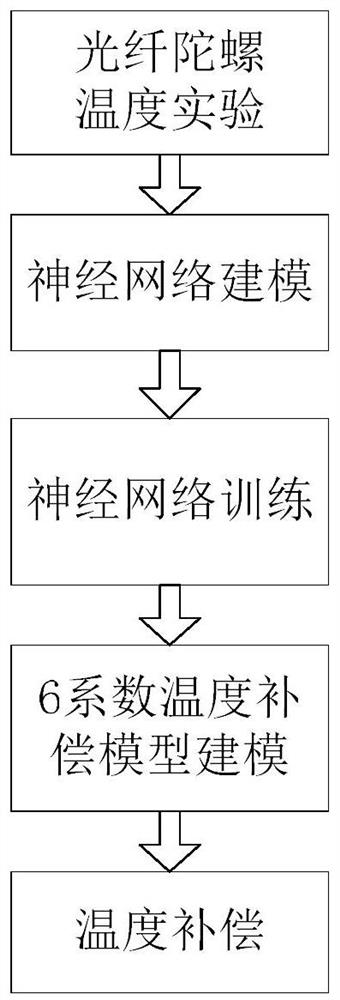

[0041] A step-by-step compensation method for fiber optic gyroscope, please refer to Figure 1-8 , its invention point is, comprises the following steps:

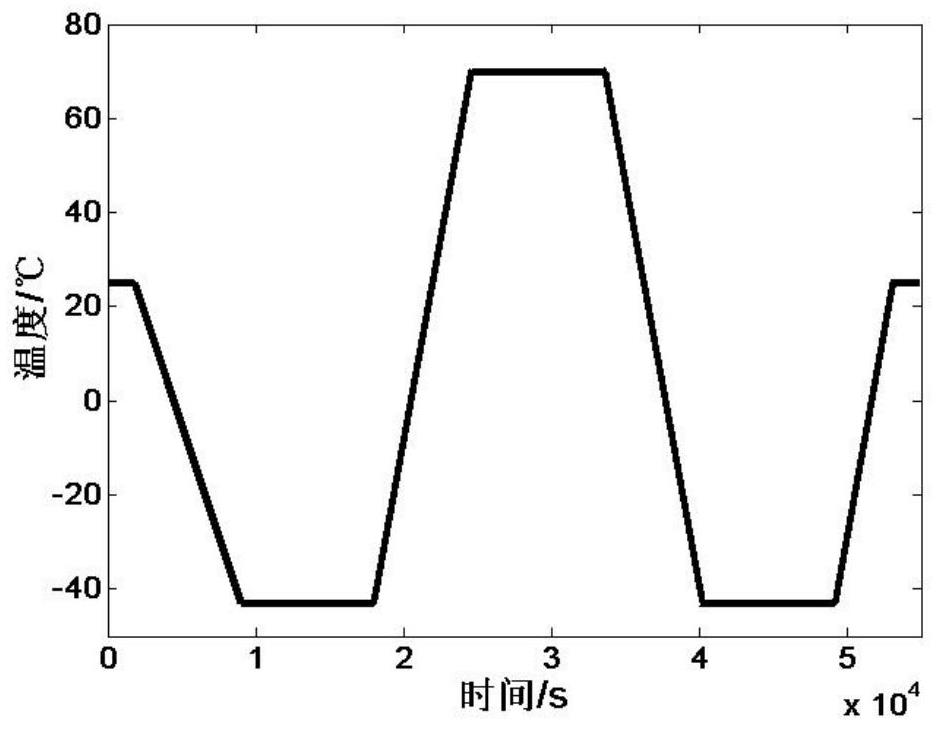

[0042] Step 1. Fiber optic gyroscope temperature experiment

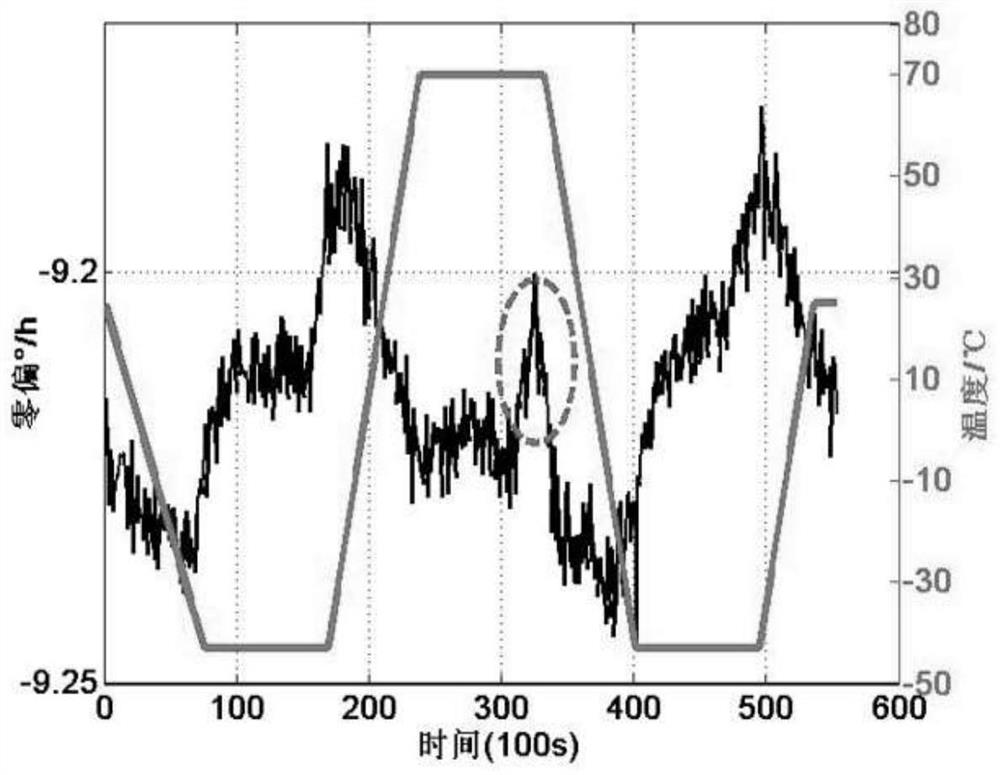

[0043] The normal temperature zero-bias stability of the experimental fiber optic gyroscope is 0.01° / h. The fiber optic gyroscope is placed in a high and low temperature test box with a vibration isolation table for testing. The sensitive axis of the gyroscope points to the sky. The temperature range of the test is -43°C- 70℃, detailed temperature curve as figure 2 shown. The data sampling interval is 1s, and the output angular velocity and temperature values of the gyroscope are collected at the same time, and the length of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com