MEMS gyroscope

A technology of gyroscopes and ring structures, applied in the field of gyroscopes, can solve the problems of low bias stability, affecting detection performance, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

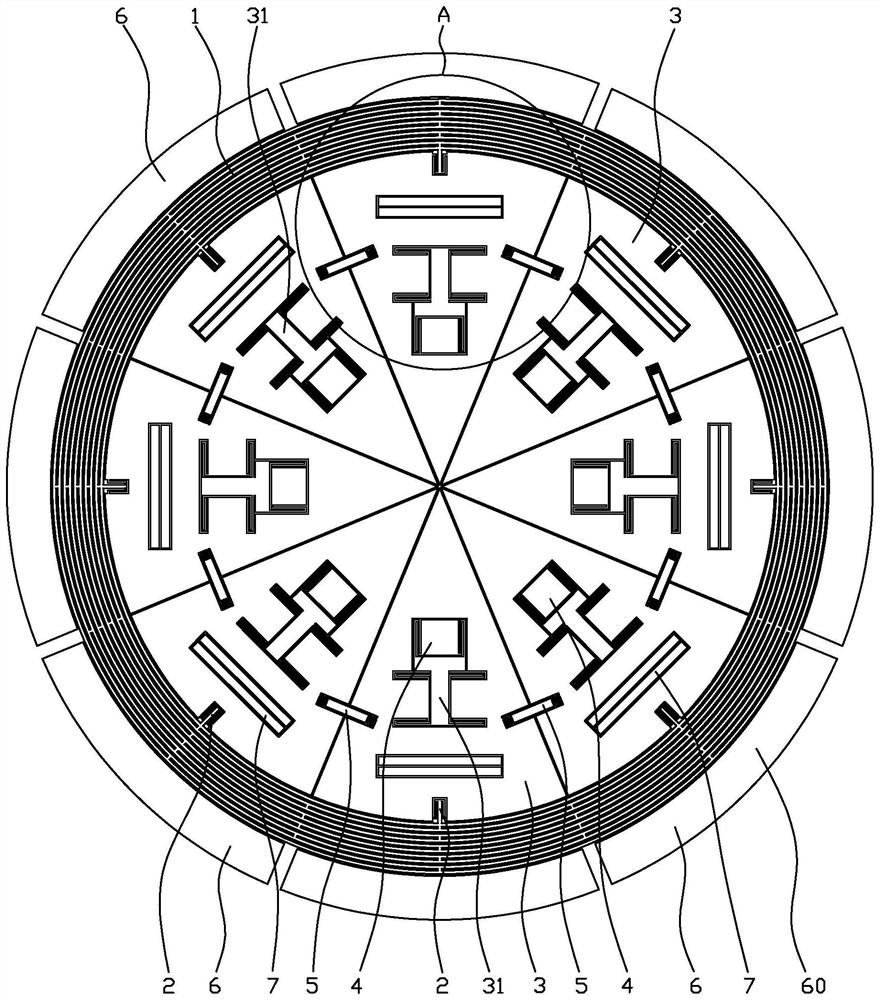

[0035] Such as figure 1 As shown, the MEMS gyroscope includes a ring structure 1, a first coupling structure 2 connected to the ring structure 1, a mass block 3 connected to the end of the first coupling structure 2 away from the ring structure 1, and an anchor point 4 connected to the mass block 3 , the second coupling structure 5 connected between adjacent mass blocks 3 and the transducer assembly 60 connected to the ring structure 1 and the mass block 3, the MEMS gyroscope includes 4N equiangular arrangements around the center of the ring structure 1 and The mass block 3 with the same size, N is an integer greater than or equal to 2, the mass block 3 includes a main body 30 connected to the first coupling structure 2 and having a receiving groove 33 inside, and an elastic structure connected to the main body 30 and located in the receiving groove 33 31 , the anchor point 4 is disposed in the receiving groove 33 and connected with the elastic structure 31 .

[0036] The ma...

Embodiment 2

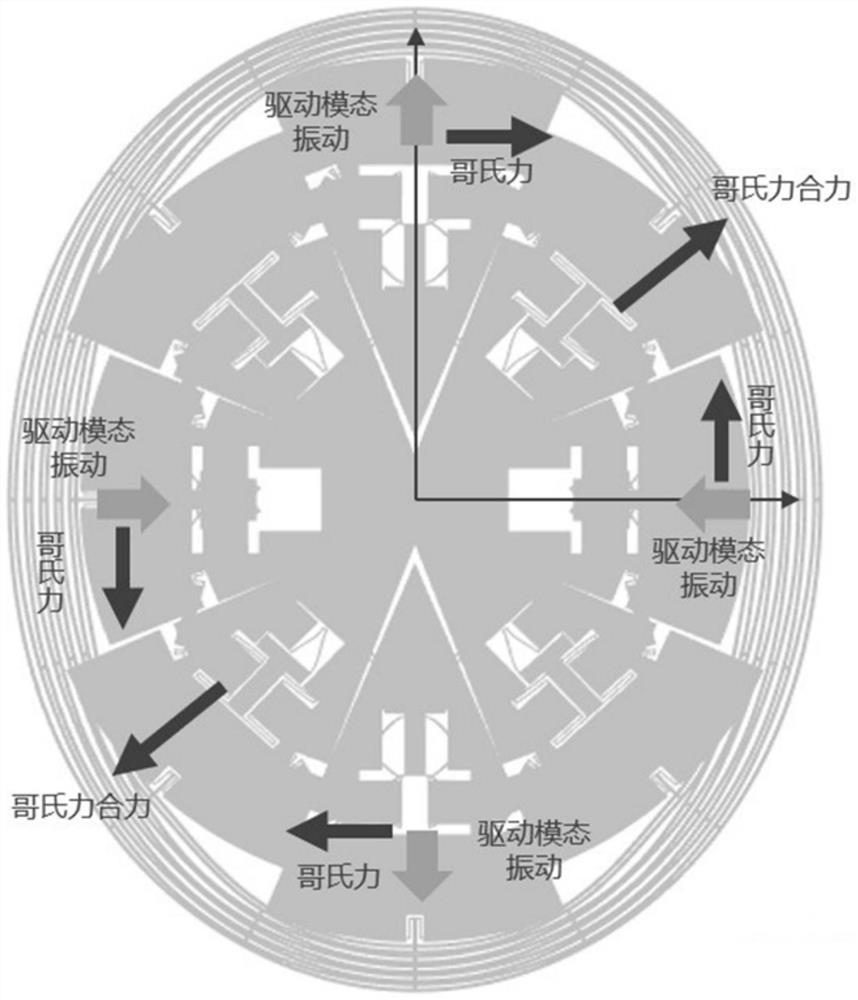

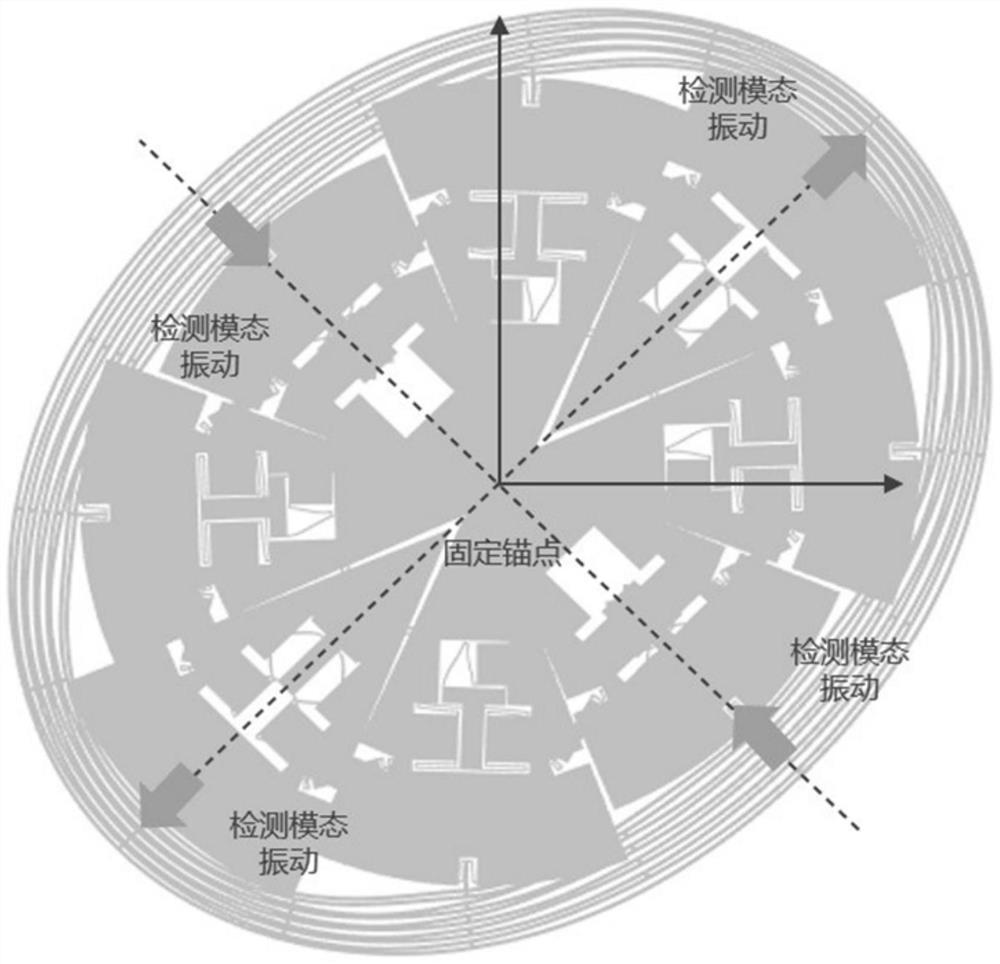

[0044] Such as Figure 7 As shown, the difference with Embodiment 1 is that in this embodiment, N is 3, that is, the mass block 3 has 12 pieces, and now the vibration mode of the MEMS gyroscope is Figure 8 As shown, the detection modality is as Figure 9 shown. In some embodiments, N can be 4, 5, 6, etc., so that the number of masses reaches 16, 20, 24, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com