Self-adaptive voltage-dividing anti-compression power transmission cable

A power transmission cable, self-adaptive technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of affecting the use of cables, the decline of recovery ability, etc., to prolong the service life, strong elastic recovery force, improve compression performance and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

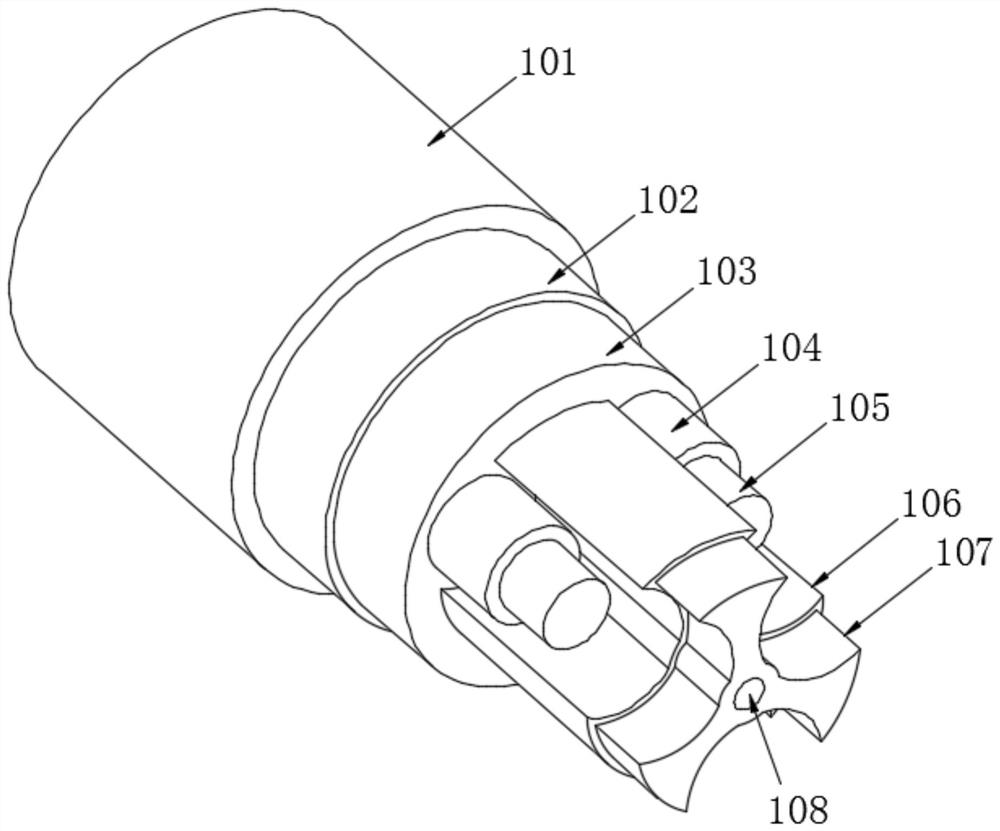

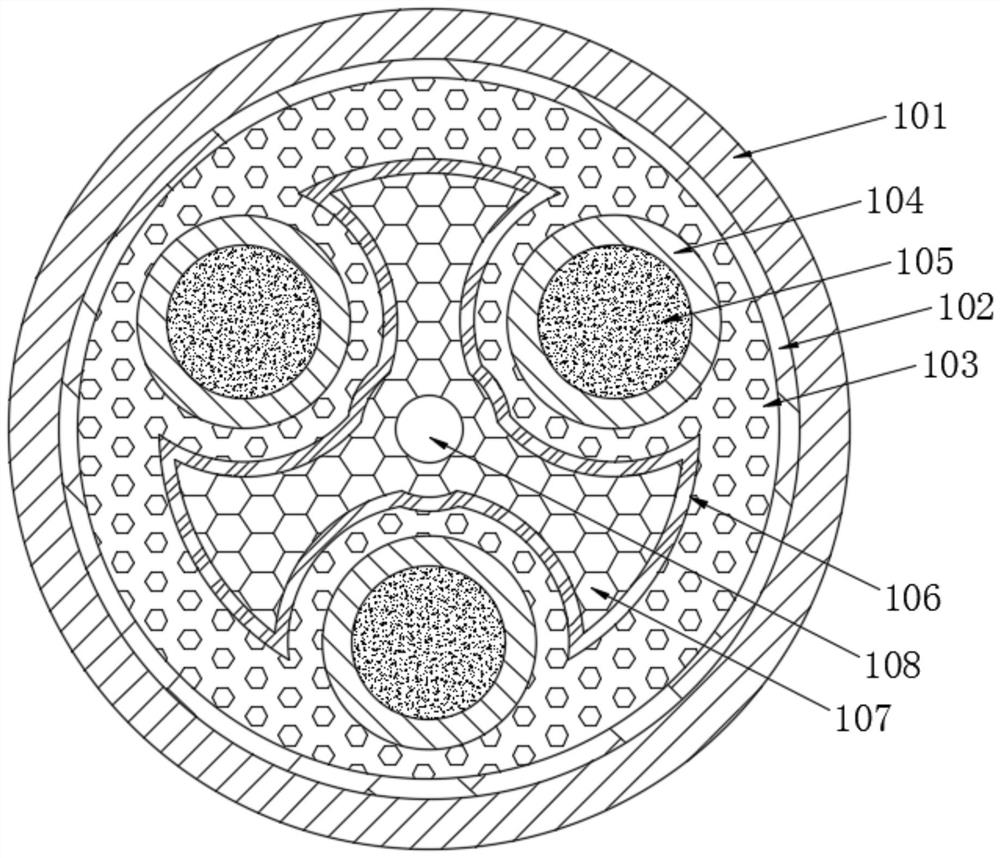

[0054] Embodiment: a kind of pressure-resistant power transmission cable of self-adaptive voltage division, such as figure 1 and figure 2 As shown, it includes an outer insulating layer 101 and three electrical core wires 105, the electrical core wires 105 are wrapped with an inner insulating layer 104, and also includes a Y-shaped pressing piece 106 composed of three branch arch pieces 109 and three inner expansion pieces 112, The branch arch pieces 109 and the inner expansion pieces 112 are arranged alternately. The three electrical core wires 105 are evenly distributed between the outer sides of adjacent branch arches 109 along the circumferential direction of the outer insulating layer 101 . An insulating filling layer 103 is provided between the outer insulating layer 101 , the branch arch piece 109 and the inner insulating layer 104 . An elastic filling layer 107 is disposed inside the Y-shaped pressing piece 106 .

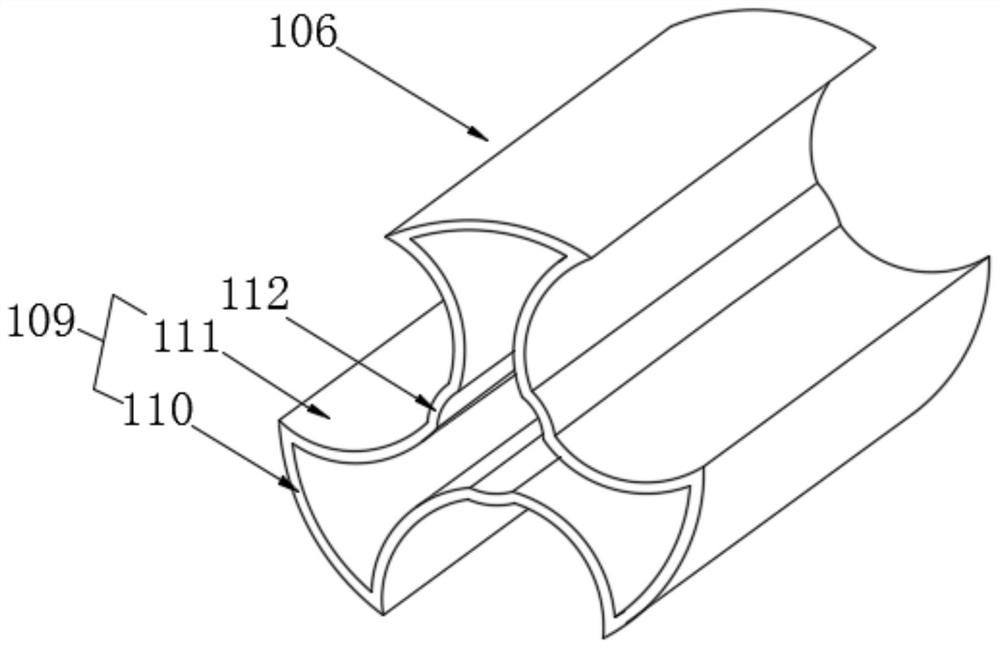

[0055] Such as image 3 As shown, the branch arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com