Extraction and purification method of industrial hemp total terpene and preparation

A technology of industrial hemp and purification method, applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, and pill delivery, etc., can solve problems such as damage, low terpene extraction rate and purity, and reduce interference , The effect of process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

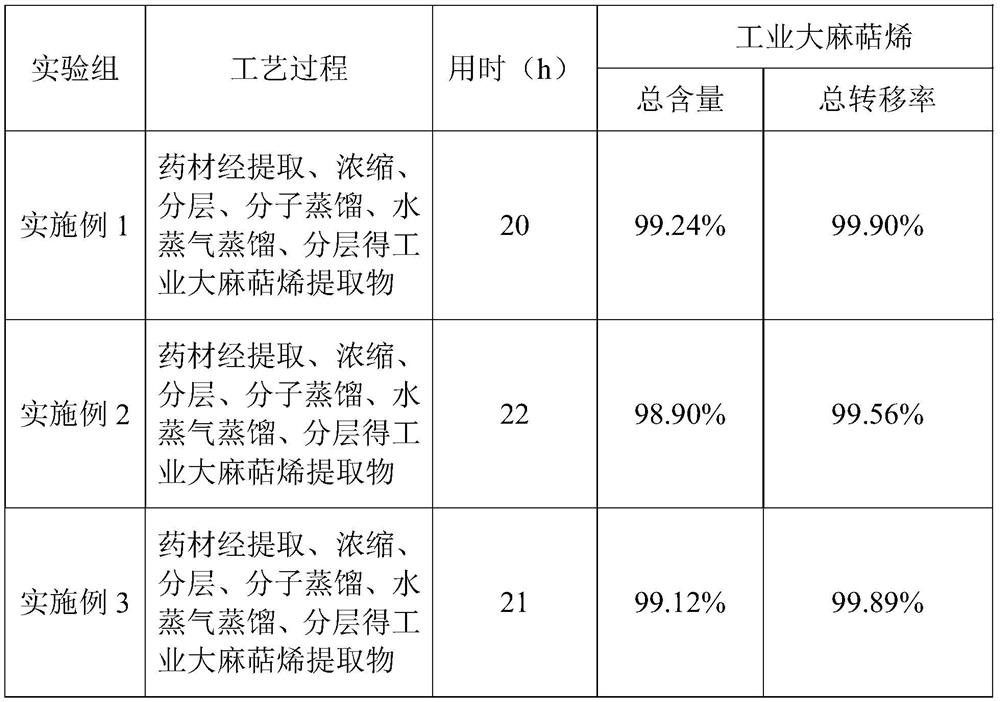

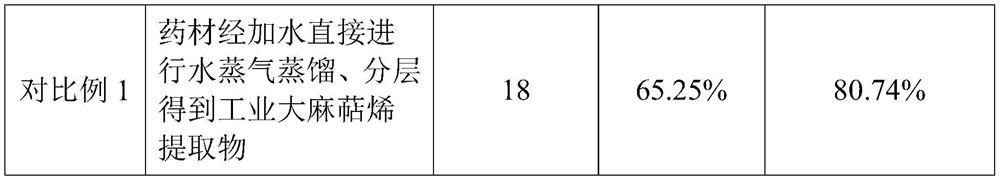

Embodiment 1

[0030] A method for extracting and purifying total terpenes of industrial hemp, comprising the following steps:

[0031] a) Industrial hemp medicinal material powder (unroasted industrial hemp leaves, industrial hemp flowers, industrial hemp roots, industrial hemp stem cores, industrial hemp seed meal or any combination of two or more) 100.00kg, add 8 times the amount of 80% ethanol was stirred and extracted at room temperature, and the extract was concentrated under reduced pressure at 60°C to obtain a concentrated solution;

[0032] b) After dispersing the concentrated solution by adding 6 times the amount of hot water, after cooling to room temperature, separate the supernatant by centrifugation;

[0033] c) Keep the supernatant liquid warm (temperature 90°C), carry out molecular distillation (pressure: -0.1Pa; temperature: 80°C; speed: 200rpm; condensation temperature: 10°C; distance between evaporation surface and condensation surface: 20mm), collect Light component, get...

Embodiment 2

[0036] A method for extracting and purifying total terpenes of industrial hemp, comprising the following steps:

[0037]a) Industrial hemp medicinal material powder (unroasted industrial hemp leaves, industrial hemp flowers, industrial hemp roots, industrial hemp stem cores, industrial hemp seed meal or any combination of two or more) 100.00kg, add 5 times the amount of 95% ethanol was stirred and extracted at room temperature, and the extract was concentrated under reduced pressure at 50°C to obtain a concentrated solution;

[0038] b) After dispersing the concentrated solution with 4 times the amount of hot water, after cooling to room temperature, separate the supernatant through centrifugation;

[0039] c) After keeping the supernatant liquid warm (temperature 80°C), carry out molecular distillation (pressure: -0.01Pa; temperature: 70°C; speed: 180rpm; condensation temperature: 5°C; distance between evaporation surface and condensation surface: 5mm), and collect Light com...

Embodiment 3

[0042] A method for extracting and purifying total terpenes of industrial hemp, comprising the following steps:

[0043] a) Industrial hemp medicinal material powder (unroasted industrial hemp leaves, industrial hemp flowers, industrial hemp roots, industrial hemp stem cores, industrial hemp seed meal or any combination of two or more) 100.00kg, add 10 times the amount of 50% ethanol was stirred and extracted at room temperature, and the extract was concentrated under reduced pressure at 70°C to obtain a concentrated solution;

[0044] b) After dispersing the concentrated solution by adding 8 times the amount of hot water, after cooling to room temperature, separate the supernatant by centrifuging and layering;

[0045] c) After keeping the supernatant liquid warm (temperature 95°C), carry out molecular distillation (pressure: -0.99Pa; temperature: 95°C; speed: 220rpm; condensation temperature: 15°C; distance between evaporation surface and condensation surface: 25mm), and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com