Preparation method of nano silver phosphate photocatalyst

A catalyst, phosphoric acid technology, applied in the field of photocatalyst, can solve the problems of easy photocorrosion and weak photocatalytic stability of a single material, and achieve the effect of improving photocatalytic degradation performance, stable catalytic performance and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

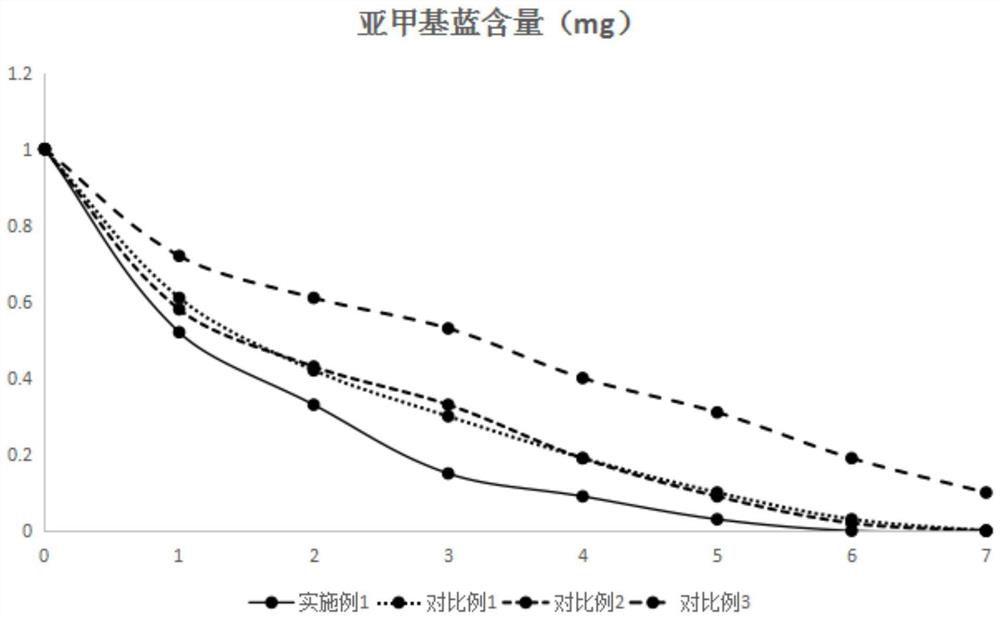

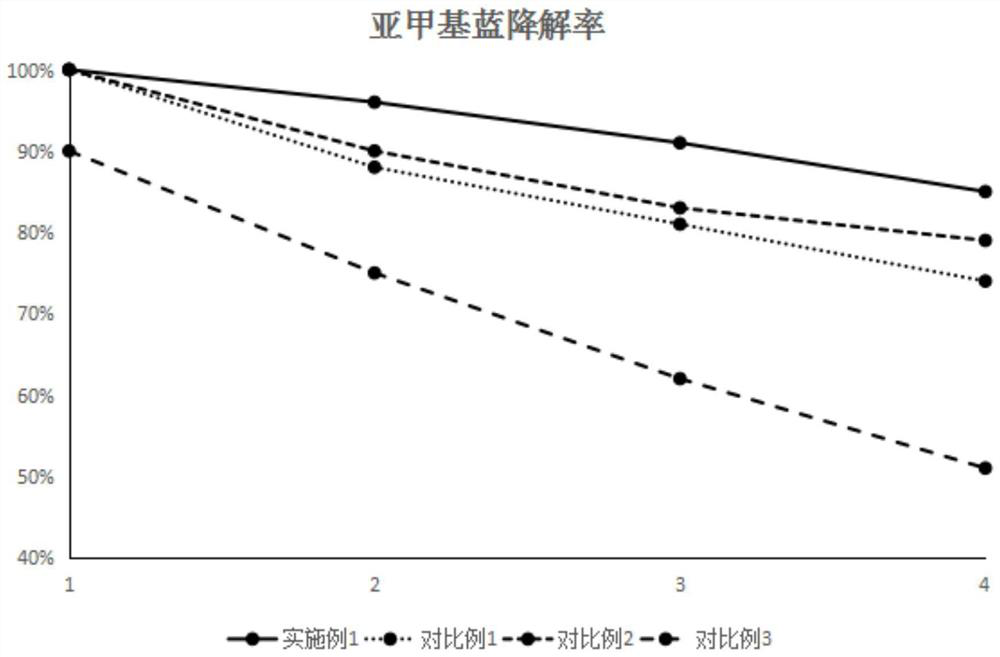

Embodiment 1

[0030] Mix 0.27g of iron powder with 0.67g of trimesic acid, then add 150ml of nitric acid and hydrofluoric acid mixed solution, wherein the volume mixing ratio of nitric acid and hydrofluoric acid is 3:2, put it in a drying oven and keep a constant temperature Dry at 140°C for 18 hours to obtain a solid powder. After alternately washing with ethanol and deionized water for 2 hours, put it in a drying oven at 80°C for 6 hours to obtain a metal-organic framework material MIL-100(Fe);

[0031] Get 1g of silver nitrate and dissolve it in 80ml of deionized water to obtain a silver nitrate solution, then add dropwise a 10wt% ammonia solution by weight at a rate of 0.5ml / min to obtain a silver ammonia solution;

[0032] Dissolve 0.5 g of disodium hydrogen phosphate dodecahydrate in 80 ml of deionized water, then add 0.1 g of molybdenum trioxide, and perform ultrasonic treatment for 15 minutes to obtain a mixed solution A;

[0033] The prepared silver ammonia solution was gradually a...

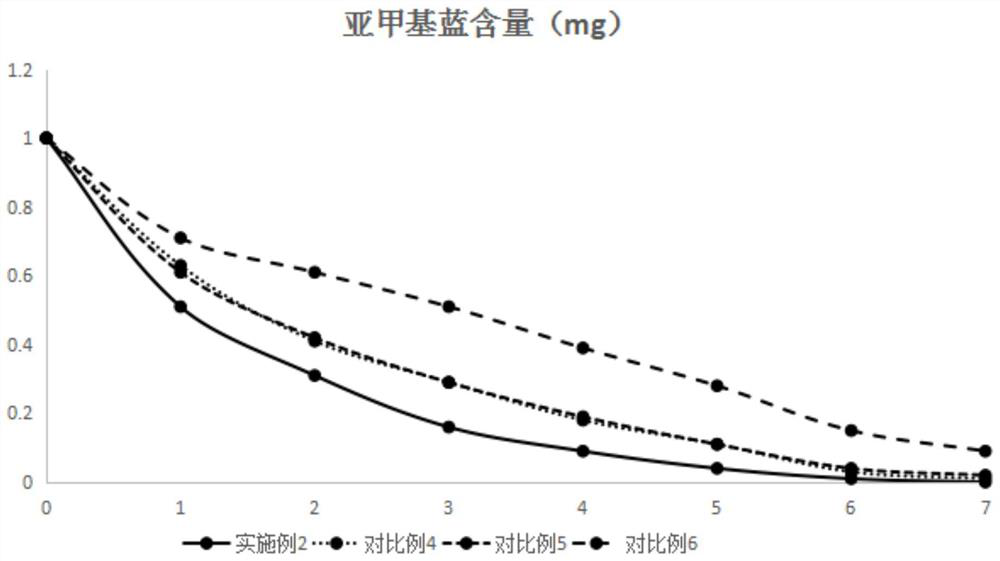

Embodiment 2

[0073] Mix 0.3g of iron powder with 0.74g of trimesic acid, then add 150ml of nitric acid and hydrofluoric acid mixed solution, wherein the volume mixing ratio of nitric acid and hydrofluoric acid is 3:2, put it in a drying oven and keep a constant temperature Dry at 180°C for 24 hours to obtain a solid powder. After alternately washing with ethanol and deionized water for 2 hours, put it in a drying oven at 80°C for 6 hours to obtain a metal-organic framework material MIL-100(Fe);

[0074] Get 3g of silver nitrate and dissolve it in 100ml of deionized water to obtain a silver nitrate solution, then add dropwise a 10wt% ammonia solution by weight at a rate of 0.5ml / min to obtain a silver ammonia solution;

[0075] Dissolve 0.8g of disodium hydrogen phosphate dodecahydrate in 100ml of deionized water, then add 0.2g of molybdenum trioxide, and perform ultrasonic treatment for 30min to obtain mixed solution A;

[0076] The prepared silver ammonia solution was gradually added drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com