Electroplating production line evaporation device with collection function

A technology of electroplating production line and evaporation device, which is applied in the direction of evaporation, separation and crystallization, special treatment targets, water/sludge/sewage treatment, etc., to achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

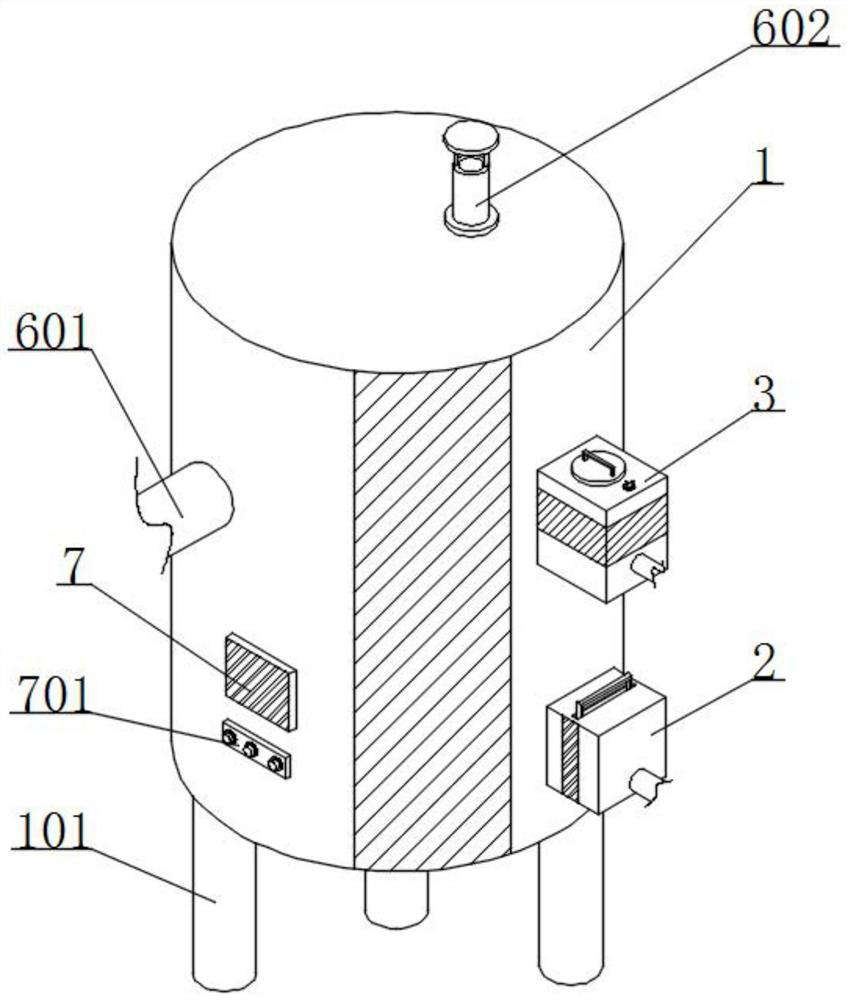

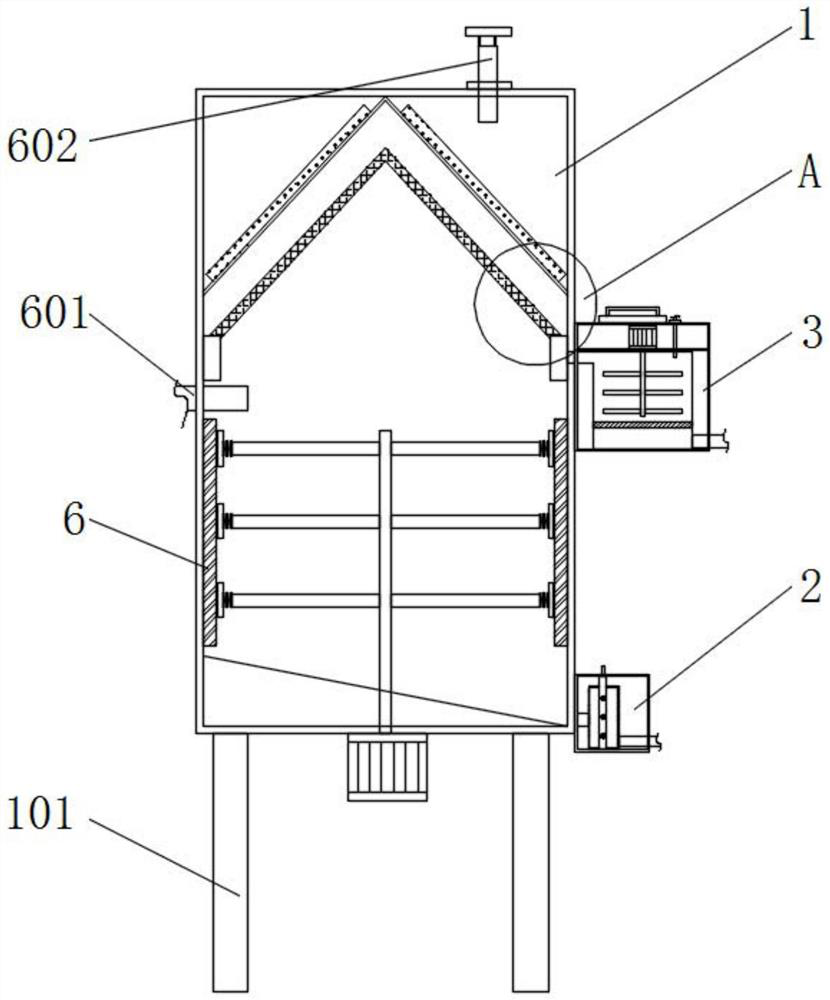

[0028] Example 1: See figure 1 and figure 2 , an electroplating production line evaporation device with a collection function, including a tank body 1, a collection box 2 and a treatment box 3, the role of the tank body 1 is to provide a place for sewage treatment, the role of the collection box 2 is to provide collection for crystallization, and the treatment box The function of 3 is to provide secondary treatment for the sewage. The outer wall of the tank body 1 is equipped with a collection box 2, the outer wall of the tank body 1 is equipped with a treatment box 3, and the inner wall of the tank body 1 is equipped with a water tank 4. Provide a flow place, the bottom of the tank body 1 is equipped with a first motor 5, the role of the first motor 5 is to provide power for the scraping of crystals, the inner wall of the tank body 1 is equipped with a heating block 6, and the effect of the heating block 6 is to clean the sewage To provide evaporation energy, a display scre...

Embodiment 2

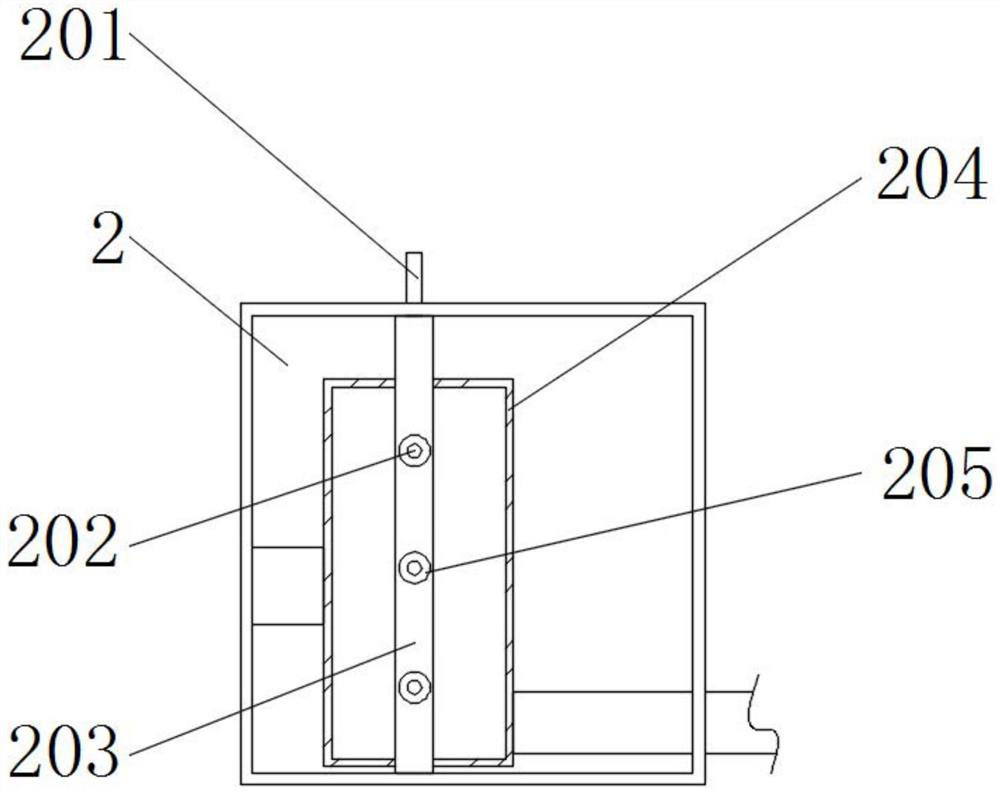

[0029] Example 2: see image 3 and Figure 6 , the inner wall of the collection box 2 is equipped with a slideway 203, the inner wall of the slideway 203 is equipped with a pulley 205, one end of the pulley 205 is equipped with a pillar 202, one end of the pillar 202 is installed with a filter box 204, and the top of the filter box 204 is equipped with a handle 201 , and one end of the handle 201 extends to the outer wall of the collection box 2, a first pipeline is installed on the outer wall of the filter box 204, a second pipeline is installed on the outer wall of the filter box 204, and one end of the second pipeline extends to the outer wall of the collection box 2, The output end of the first motor 5 is equipped with a rotating rod 504, the outer wall of the rotating rod 504 is equipped with a second pole 501, one end of the second pole 501 is equipped with a spring 502, and one end of the spring 502 is equipped with a scraper 503, slideway The function of 203 is to pro...

Embodiment 3

[0030] Example 3: See Figure 4 and Figure 5, the inner wall of the processing box 3 is equipped with a first pole, the outer wall of the first pole is equipped with a second motor 301, the output end of the second motor 301 is equipped with a stirring blade 305, and the inner wall of the processing box 3 is equipped with a first filter screen 302 A box cover 303 is installed on the top of the process box 3, a third pipeline 304 is installed through the top of the process box 3, a fourth pipeline is installed through the outer wall of the process box 3, a fifth pipeline is installed through the outer wall of the process box 3, the sink The outer wall of 4 is equipped with a second filter screen 401, the inner wall of the tank body 1 is equipped with a temperature transfer plate 403, the outer wall of the temperature transfer plate 403 has a condensation block 402, the effect of the box cover 303 is to facilitate the cleaning of the processing box 3, the first The function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com